1 To 1 Isolation Transformer

CN

CN

TW

TW

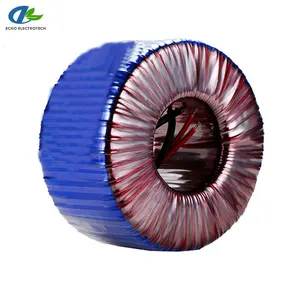

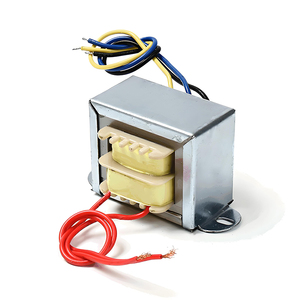

About 1 to 1 isolation transformer

Where to Find 1 to 1 Isolation Transformer Suppliers?

China remains the global epicenter for 1 to 1 isolation transformer manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated supply chains that streamline core material sourcing—such as copper windings, nickel-steel laminations, and permalloy sheets—and support rapid prototyping and mass production. Shenzhen-based manufacturers specialize in compact, PCB-mounted audio and pulse transformers, while Zhejiang and Jiangsu facilities focus on industrial-grade safety and power isolation units rated up to 10KVA.

The industrial ecosystem enables economies of scale, with localized access to precision winding machines, encapsulation systems, and automated testing equipment. This integration reduces lead times for standard models to 15–25 days and supports low minimum order quantities (MOQs), some as small as 1 piece. Buyers benefit from competitive pricing structures, with unit costs ranging from $0.30 for miniature signal transformers to over $7,500 for high-capacity power units, depending on specifications and volume.

How to Choose 1 to 1 Isolation Transformer Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capabilities

Verify that suppliers can meet required electrical parameters including voltage rating, frequency response, insulation resistance, and dielectric strength (hi-pot testing). For medical or audio applications, assess phase accuracy and electromagnetic interference (EMI) suppression performance. Suppliers offering customization should provide full control over core material (EI, toroidal, SMD), wire gauge, encapsulation type, and labeling.

Production and Quality Assurance Infrastructure

Evaluate supplier capabilities based on the following indicators:

- On-time delivery rate exceeding 95%

- Response time under 6 hours for inquiry resolution

- In-house engineering support for design adjustments

- Use of certified materials (e.g., RoHS-compliant copper, UL-listed insulation)

Manufacturers with online revenue exceeding US $40,000 annually demonstrate consistent market presence and export readiness. Prioritize those offering product tagging options such as custom color coding, branding labels, and phase-specific configurations.

Transaction Risk Mitigation

Leverage secure payment mechanisms and pre-shipment inspections. Analyze reorder rates as a proxy for customer satisfaction—rates above 20% indicate strong product reliability. For high-volume procurement, request sample batches to validate consistency in weight, size, and electrical performance before scaling orders.

What Are the Best 1 to 1 Isolation Transformer Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Jiangsu First Power Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $770,000+ | 100% | ≤3h | 55% | Yes | 1 piece |

| Zhejiang Kaiyi Electric Co., Ltd. | Zhejiang, CN | — | US $30,000+ | 100% | ≤1h | 20% | No | 5 sets |

| Shaanxi Magason-Tech Electronics Co., Ltd. | Shaanxi, CN | Multispecialty Supplier | US $40,000+ | 95% | ≤6h | 18% | Yes | 1 piece |

| Shenzhen Hyst Technology Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | US $10,000+ | 100% | ≤4h | 20% | No | 1 piece |

| Shenzhen Zhixiangyuan Electronics Co., Ltd. | Shenzhen, CN | Custom Manufacturer | US $20,000+ | 96% | ≤5h | <15% | Yes | 5 pieces |

Performance Analysis

Jiangsu First Power leads in scalability and customer retention, with a 55% reorder rate and capacity to deliver large-scale power transformers (up to 1000KVA) compliant with ANSI, CE, and UL/CUL standards. Zhejiang Kaiyi Electric excels in fast response times (under 1 hour) and specializes in safety-rated isolation units for industrial environments. Shenzhen-based suppliers like Hyst Technology and Zhixiangyuan offer ultra-low MOQs ideal for R&D and pilot testing, though lower reorder rates suggest room for improvement in long-term satisfaction. Shaanxi Magason-Tech provides extensive customization in core design and labeling, suitable for OEM integration.

FAQs

How to verify 1 to 1 isolation transformer supplier reliability?

Cross-check claimed certifications (CE, UL, ISO) through official databases. Request test reports for insulation resistance, turns ratio, and thermal performance. Assess supplier credibility via documented on-time delivery history, response efficiency, and transaction volume.

What is the typical sampling timeline?

Standard samples are typically shipped within 7–14 days. Custom designs may require 20–30 days depending on complexity. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate custom specifications?

Yes, select manufacturers support full customization of core material, winding configuration, packaging, and branding. Confirm availability of engineering support and request validation through prototype testing before bulk ordering.

Do suppliers offer free samples?

Policies vary. Some suppliers provide paid samples refundable against future orders. Others charge full cost for initial units, especially for high-power models. Free samples are rare but negotiable for potential high-volume contracts.

What are common MOQ and pricing structures?

MOQ ranges from 1 piece for signal transformers to 5,000 pieces for commodity-level components. Unit prices span $0.30 for basic audio isolators to $161 for 3KVA safety units. Volume discounts are standard, particularly beyond 1,000-unit thresholds.