2 Channel Relay Module Producer

1/23

1/23

1/24

1/24

1/11

1/11

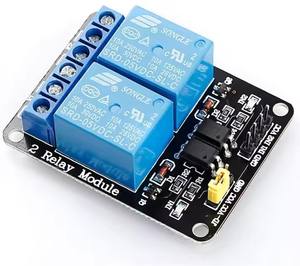

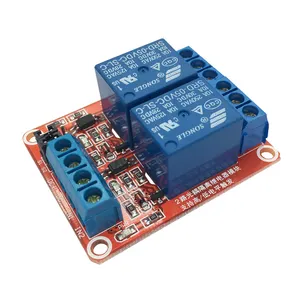

About 2 channel relay module producer

Where to Find 2 Channel Relay Module Producers?

China remains the central hub for 2 channel relay module manufacturing, with key production clusters in Shenzhen and Foshan offering vertically integrated supply chains. These regions host specialized electronics manufacturers that operate dedicated production lines for industrial control components, including relay modules. Shenzhen’s ecosystem benefits from proximity to semiconductor suppliers and PCB fabrication facilities, enabling rapid prototyping and high-volume output. Foshan-based producers leverage established partnerships with component distributors, reducing lead times by up to 25% compared to non-specialized regions.

The concentration of technical expertise and supporting infrastructure allows for efficient scaling across order volumes. Suppliers in these zones typically maintain in-house SMT lines, automated testing stations, and quality control systems, ensuring consistency in performance-critical applications. Buyers benefit from localized sourcing networks where design, assembly, and logistics services are co-located, facilitating faster time-to-market. Typical advantages include MOQs as low as 1–5 pieces for sampling, scalable production capacity (up to 100K units/month), and competitive pricing driven by economies of scale.

How to Choose 2 Channel Relay Module Suppliers?

Procurement decisions should be guided by objective evaluation criteria focused on operational reliability and technical capability:

Production Infrastructure Verification

Confirm ownership of dedicated production lines through facility documentation or video audits. Prioritize suppliers with demonstrated automation capabilities—such as automated optical inspection (AOI) and functional testing rigs—for consistent unit-to-unit performance. Evaluate engineering support availability for custom configurations involving voltage specifications (e.g., 3.3V, 5V, 12V, 24V), signal isolation, or DIN rail mounting.

Quality & Compliance Indicators

While formal certifications like ISO 9001 or RoHS compliance may not always be explicitly stated, use indirect metrics to assess quality discipline:

- On-time delivery rate ≥98% indicates stable internal processes

- Response time ≤4 hours reflects organizational responsiveness

- Online transaction volume exceeding US $70,000/year suggests market validation

For export-bound orders, verify compatibility with destination-market standards such as CE marking for EU shipments or UL recognition for North American integration.

Transaction Risk Mitigation

Utilize secure payment methods with dispute resolution mechanisms, particularly when engaging newer suppliers. Request sample units before bulk ordering to validate electrical performance, build quality, and labeling accuracy. Assess reorder rate data: a rate below 15% may indicate customer retention issues, while higher rates (>25%) suggest satisfaction but could also reflect limited alternative sourcing options.

What Are the Leading 2 Channel Relay Module Producers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Shenzhen Dawangtai Electronics Co., Ltd. | Shenzhen, CN | Motor Driver Boards, Audio Modules, Relays, Connectors | 98% | ≤4h | <15% | US $50,000+ | 1 piece (some SKUs) |

| Foshan Qingjun Electronics Co., Ltd. | Foshan, CN | PLCs, Relays, Push Buttons, HMI, Power Supplies | 100% | ≤2h | <15% | US $70,000+ | 5 pieces |

| Shenzhen Robotlinking Technology Co., Ltd. | Shenzhen, CN | Development Boards, Electronic Modules, Robotics Kits | 87% | ≤5h | 25% | US $170,000+ | 2 pieces |

| Aocgo Electric Co., Ltd. | China | Relays, Industrial Components, PCBA, Connectors | 83% | ≤5h | <15% | US $3,000+ | 5 pieces |

| Shenzhen XMS Technology Co., Ltd. | Shenzhen, CN | Electronic Components, ICs, Inverters, Connectors | 100% | ≤2h | 18% | US $70,000+ | 5 pieces |

Performance Analysis

Foshan Qingjun and Shenzhen XMS stand out with 100% on-time delivery records and sub-2-hour average response times, indicating strong operational discipline. Shenzhen Robotlinking reports the highest online revenue (US $170,000+), suggesting significant market reach, though its 87% on-time delivery rate presents a moderate risk factor. Aocgo Electric has the lowest reported revenue and delivery performance, which may affect scalability assurance. Suppliers based in Shenzhen dominate in product diversity, especially in development-focused segments like USB-controlled or wireless relay modules. For industrial integration, prioritize partners with proven experience in PLC-compatible designs and signal isolation techniques.

FAQs

What is the typical MOQ for 2 channel relay modules?

Standard MOQs range from 1 to 5 pieces for sample validation, with bulk pricing applying at 10–100 units depending on the supplier. High-volume orders (5,000+ units) can negotiate customized packaging and branding.

How long does production and shipping take?

Lead time for standard units is typically 7–15 days after order confirmation. Air freight adds 5–10 days for international delivery. Custom modifications may extend timelines by 7–14 days based on design complexity.

Can I request customized specifications?

Yes, many producers support customization of input voltage (3.3V–24V), trigger logic (high/low level), contact configuration (SPDT/DPDT), and physical form factor. Some offer firmware integration for time-delay or Modbus-enabled variants. Confirm feasibility via technical inquiry prior to ordering.

Are samples available for testing?

Most suppliers provide samples at listed prices, often without additional fees beyond unit cost and shipping. Sample orders are recommended to evaluate insulation quality, switching noise, LED indicators, and PCB layout before mass procurement.

Do these modules comply with safety standards?

While explicit certification data is not provided, many units feature optical isolation, transient protection, and flame-retardant PCB materials. For regulated environments, require compliance documentation for CE, RoHS, or UL standards directly from the manufacturer prior to deployment.