2 Row Radiator Vs 4 Row

1/16

1/16

1/32

1/32

1/24

1/24

1/33

1/33

1/36

1/36

About 2 row radiator vs 4 row

Where to Find 2 Row vs 4 Row Radiator Suppliers?

China serves as the central hub for aluminum radiator manufacturing, with key production clusters in Shandong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated facilities specializing in automotive cooling systems, leveraging localized access to raw materials, CNC machining centers, and export logistics networks. The concentration of technical expertise and supply chain density enables competitive pricing, scalable output, and rapid prototyping for both standard and custom radiators.

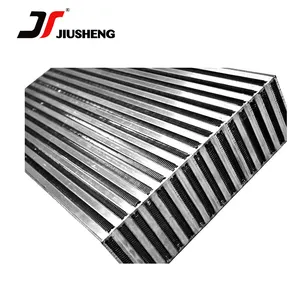

Suppliers in this sector primarily focus on full-aluminum construction using tube-fin or bar-plate core designs, optimized for thermal efficiency and durability. Production capabilities range from small-batch OEM replacements to high-volume aftermarket exports, with average monthly outputs exceeding 1,000 units per facility. Core processing techniques include TIG welding, vacuum brazing, and pressure testing up to 30 psi, ensuring structural integrity under sustained thermal load. Buyers benefit from short lead times (typically 15–30 days), flexible MOQs starting at 1 piece, and customization options including row count, inlet diameter, shroud integration, and fin density.

How to Choose 2 Row vs 4 Row Radiator Suppliers?

Effective supplier evaluation requires systematic assessment across three critical dimensions:

Technical Capability Verification

Confirm that suppliers utilize full-aluminum cores with precision-fin spacing and robust header tanks. For performance applications, verify use of 4-row or heavy-duty 70mm-thick cores capable of dissipating higher heat loads. Request pressure test reports (minimum 25 psi) and material certifications confirming 3003/6061 aluminum alloys. For racing or industrial use cases, ensure compatibility with ethylene glycol-based coolants and resistance to thermal cycling fatigue.

Production & Quality Infrastructure

Assess operational scale through verifiable metrics:

- Facility size and dedicated R&D capacity for thermal modeling

- In-house tooling and CNC bending/welding lines to minimize outsourcing

- On-site quality control protocols, including flow testing and leak detection

Prioritize suppliers reporting on-time delivery rates above 95% and response times under 6 hours, indicators of operational discipline and customer service maturity.

Procurement Risk Mitigation

Utilize transaction safeguards such as third-party inspections prior to shipment and incremental payment terms. Validate fitment accuracy by requesting dimensional drawings or CAD models before order confirmation. When sourcing universal or racing-spec units, confirm interchangeability with OEM part numbers and vehicle-specific mounting configurations. Sample testing is recommended to benchmark cooling efficiency and structural resilience under real-world conditions.

What Are the Best 2 Row vs 4 Row Radiator Suppliers?

| Company Name | Location | Verified Status | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Weihai Hengxing Auto Parts Co., Ltd. | Shandong, CN | Custom Manufacturer | Radiators, Cooling Systems | 100% | ≤3h | 16% | US $80,000+ | Color, material, size, logo, packaging, graphics |

| Yangzhou Benos Auto Parts Co., Ltd. | Jiangsu, CN | Custom Manufacturer | Radiators, Fan Systems, Racing-Spec Units | 100% | ≤4h | <15% | US $30,000+ | Fan included, thickness, row count, core material, CNC-machined aluminum, fitment specs |

| Taizhou Sute Auto Parts Co., Ltd. | Zhejiang, CN | - | Radiators, Intercoolers, Pipe Fittings | 100% | ≤18h | <15% | - | Limited |

| Shanghai Speedmaster Auto Parts Co., Ltd. | Shanghai, CN | - | Radiators, Rubber Hoses, Motorcycle Cooling Systems | 89% | ≤6h | <15% | US $60,000+ | Standard product range |

| Yangzhou Linte Auto Parts Co., Ltd. | Jiangsu, CN | - | Radiators | - | ≤5h | <15% | US $100+ | Model-specific variants |

Performance Analysis

Weihai Hengxing and Yangzhou Benos stand out as leading suppliers due to verified custom manufacturing status, 100% on-time delivery records, and comprehensive customization capabilities. Both support racing-grade and application-specific designs, with Benos offering granular control over core thickness, row configuration, and CNC-machined components. Weihai Hengxing demonstrates strong reorder volume and fast response cycles, indicating reliable post-sale support. Taizhou Sute achieves perfect delivery performance but offers limited customization and lacks revenue transparency. Shanghai Speedmaster maintains a broad product portfolio and solid financial activity, though its 89% on-time rate suggests occasional fulfillment delays. Yangzhou Linte operates at lower visibility with minimal reported data, suitable for low-risk, small-volume trials.

FAQs

What is the difference between 2 row and 4 row radiators?

A 2-row radiator uses two layers of tubes for coolant flow, offering adequate cooling for standard engines. A 4-row design doubles the tube count, increasing surface area and heat dissipation—ideal for high-performance, towing, or off-road applications where thermal load is significantly higher. However, 4-row units may introduce airflow resistance if not properly matched to fan capacity and grille clearance.

What are typical MOQs and pricing for aluminum radiators?

MOQs vary from 1 piece (sample orders) to 30–50 pieces for bulk pricing. 2-row radiators typically range from $65–$120/unit, while 4-row models command $95–$145 due to increased material and labor costs. Volume discounts are common beyond 50 units.

Can suppliers customize radiator dimensions and fittings?

Yes, many manufacturers offer full customization of core size, tank orientation, inlet/outlet diameter, and mounting brackets. Verified custom producers provide engineering support, including CAD drawings and prototype validation, to ensure proper fitment and performance.

What quality tests should radiators undergo before shipment?

All units should pass hydrostatic or air pressure testing (minimum 25 psi) to detect leaks. Reputable suppliers conduct flow rate verification and visual inspection of brazing joints. For export shipments, request test certificates or video evidence of quality checks.

How long does production and shipping take?

Lead time averages 15–25 days for production, plus 5–10 days for international air freight or 25–40 days via sea container. Express sampling is available within 7–14 days for urgent evaluations.