2 Rule Turing Machine

CN

CN

About 2 rule turing machine

Where to Find 2 Rule Turing Machine Suppliers?

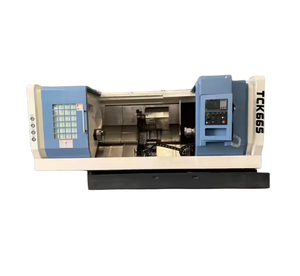

China remains the central hub for industrial automation and precision machining equipment, including specialized turning machinery often referenced under the term "2 rule turing machine"—a designation typically associated with dual-spindle or dual-turret CNC lathes designed for high-efficiency, simultaneous machining operations. Key manufacturing clusters are concentrated in Jiangsu, Shandong, and Guangdong provinces, where vertically integrated supply chains and mature metalworking ecosystems enable competitive production.

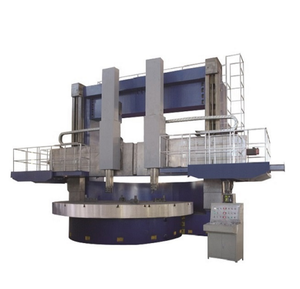

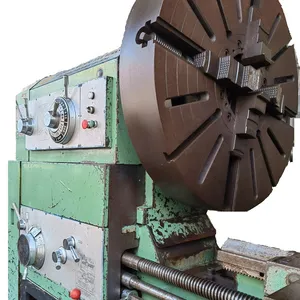

Jiangsu and Shandong host leading suppliers of high-precision CNC turning centers, leveraging proximity to steel suppliers and component manufacturers to reduce material costs by 15–25%. Dongguan-based firms specialize in compact, semi-automatic turning systems for wire processing and terminal manufacturing, while Shandong and Dalian facilities focus on heavy-duty vertical and horizontal turning lathes for large-scale industrial applications. These regional advantages translate into shorter lead times—typically 45–60 days for standard configurations—and enhanced flexibility for customization in control systems, tooling layouts, and automation integration.

How to Choose 2 Rule Turing Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer machines equipped with dual-spindle or dual-turret configurations capable of executing independent yet synchronized machining cycles. Key specifications to validate include spindle bore size, tool post count, CNC system brand (e.g., Fanuc, Siemens, or equivalent), and optional live tooling or bar feeder compatibility. Request detailed CAD drawings or 3D renderings to verify work envelope dimensions and functional alignment with production requirements.

Production Infrastructure Assessment

Evaluate supplier capacity based on the following benchmarks:

- Minimum factory area exceeding 5,000m² for sustained volume output

- In-house CNC machining and assembly lines to ensure quality control

- Demonstrated R&D capability, particularly in multi-axis synchronization and energy-efficient drive systems

Cross-reference online revenue indicators and order fulfillment history (e.g., 100% on-time delivery rates observed in multiple suppliers) as proxies for operational stability.

Quality & Transaction Assurance

Prioritize suppliers with documented adherence to international quality standards such as ISO 9001. While explicit CE certification is not uniformly listed, verify compliance readiness for export markets through available safety documentation and electrical system design. Utilize secure payment mechanisms and request pre-shipment inspection rights. Sample testing is strongly advised—assess machining accuracy, surface finish consistency, and thermal stability during extended operation before scaling procurement.

What Are the Best 2 Rule Turing Machine Suppliers?

| Company Name | Location | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Leichman Automation Technology Co., Ltd. | Jiangsu, CN | High-precision dual-spindle CNC lathes | $23,000–55,000 | 1 set | 100% | ≤5h | 66% | $120,000+ |

| Dongguan Turing Automation Technology Co., Ltd. | Guangdong, CN | Semi-automatic and electric CNC turning systems | $286–2,250 | 1 set | 100% | ≤4h | Not Available | Unspecified |

| Shandong Youtai Machine Tool Manufacturing Co., Ltd. | Shandong, CN | Vertical double-turret and double-end turning machines | $43,999–80,999 | 1 set | 100% | ≤2h | <15% | $120,000+ |

| Dalian Haidi Machinery Co., Ltd. | Liaoning, CN | Heavy-duty manual and CNC vertical turning lathes | $29,500–100,000 | 1 piece | 100% | ≤2h | 50% | $210,000+ |

| Tengzhou Hoyong Machinery Co., Ltd. | Shandong, CN | Universal turret milling and manual turning machines | $3,000–5,500 | 1 set | 100% | ≤4h | <15% | $10,000+ |

Performance Analysis

Jiangsu Leichman stands out for its mid-to-high-end CNC lathe offerings and strong customer retention (66% reorder rate), indicating consistent product satisfaction. Dongguan Turing provides cost-effective solutions for light industrial applications, with entry-level models starting below $300, making it suitable for prototyping or small-batch production. Shandong Youtai and Dalian Haidi serve the upper tier of demand with large-format vertical turning centers priced above $40,000, backed by robust build quality and scalable customization. Tengzhou Hoyong offers economical manual turret machines, though its lower online revenue suggests limited export scale. Buyers seeking automation-ready, high-throughput systems should prioritize suppliers offering live tooling, bar feeders, and CNC integration options.

FAQs

What does '2 rule turing machine' mean in industrial contexts?

The term refers to CNC turning machines with dual operational rules—commonly interpreted as dual spindles or dual turrets—enabling parallel machining tasks such as simultaneous cutting on both ends of a workpiece, significantly improving productivity and dimensional consistency.

What are typical MOQ and lead times?

Minimum order quantity is universally 1 unit/set. Lead times range from 30–45 days for standard models and extend to 60 days for customized configurations involving special tooling, control systems, or automation interfaces.

Do suppliers support customization?

Yes, major suppliers offer customization in CNC system selection, tool post diameter, swing over bed, spindle speed, and integration with bar feeders or robotic loaders. Some also provide OEM branding, packaging labels, and graphic interface modifications.

Are samples available before bulk orders?

Sample availability depends on machine complexity. For smaller units (e.g., semi-automatic wire strippers), suppliers may offer demonstration units. For large CNC systems, virtual walkthroughs or factory test runs are more common than physical sampling due to logistics constraints.

How are shipments handled internationally?

Suppliers support global shipping via sea freight (FCL/LCL) for full machines. Packaging is typically wooden crate export-standard. Buyers should confirm Incoterms (FOB, CIF), customs clearance responsibilities, and destination-side installation support prior to order confirmation.