3 Phase 3 Wire And 3 Phase 4 Wire System

About 3 phase 3 wire and 3 phase 4 wire system

Where to Find 3 Phase 3 Wire and 3 Phase 4 Wire System Suppliers?

China remains the central hub for manufacturing electrical power systems, with key suppliers of 3 phase 3 wire and 3 phase 4 wire systems concentrated in Zhejiang, Anhui, Fujian, and Shandong provinces. These regions host specialized industrial clusters focused on medium-voltage and low-voltage power distribution equipment, supported by mature supply chains for transformers, capacitors, reactors, and switchgear components. Zhejiang and Anhui are particularly notable for their concentration of reactive power compensation and harmonic filtering technology providers.

Suppliers in these zones benefit from vertically integrated production ecosystems, enabling rapid prototyping and scalable manufacturing. Many operate facilities equipped with CNC machining centers, automated assembly lines, and in-house testing laboratories for IEC and ANSI compliance validation. This infrastructure supports competitive lead times—typically 20–45 days for standard units—and cost advantages, with localized sourcing reducing material expenses by 15–25% compared to Western producers. Buyers gain access to a diverse product range, including static var generators (SVG), active harmonic filters (AHF), capacitor banks, and automatic power factor correction systems designed for both industrial and commercial applications.

How to Choose 3 Phase 3 Wire and 3 Phase 4 Wire System Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international standards such as IEC 61000-3-2 (harmonic emissions), IEEE 519 (power quality), and IEC 60831 (shunt capacitors). For grid-connected or industrial installations, verify product-level certifications including CE, CB Scheme, or national type-test reports. Request test data for efficiency, THD (Total Harmonic Distortion) reduction, response time (<10ms for SVGs), and operating temperature ranges (-25°C to +55°C typical).

Production Capability Audits

Assess core manufacturing competencies through the following indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

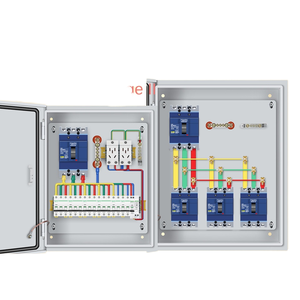

- In-house design and R&D teams capable of system customization (e.g., 3P3W vs. 3P4W configurations)

- Integrated production lines covering PCB assembly, coil winding, enclosure fabrication, and final system integration

- On-site dielectric and thermal performance testing under load conditions

Cross-reference online transaction records showing consistent on-time delivery (>97%) and low dispute rates.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to ensure product verification prior to full disbursement. Evaluate supplier responsiveness (target ≤4 hours) and reorder rate as proxies for customer satisfaction. Prioritize vendors offering sample units for field testing—critical for validating harmonic filtering efficacy and dynamic reactive power compensation before large-scale deployment.

What Are the Best 3 Phase 3 Wire and 3 Phase 4 Wire System Suppliers?

| Company Name | Main Products | Product Range (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Value | Customization |

|---|---|---|---|---|---|---|---|

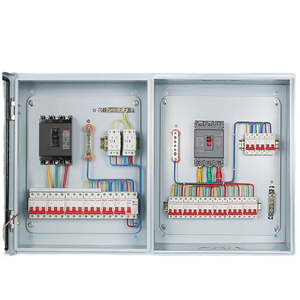

| Zhejiang Nengrong Electric Power Equipment Co., Ltd. | SVG, Reactive Power Compensation, Harmonic Filters | 4+ high-power systems ($2,000–$2,450/set) | 100% | ≤2h | <15% | $2,000 | Limited (standard models) |

| Anhui Zhongdian Electric Co., Ltd. | Active Harmonic Filters, Capacitor Banks, PFC Systems | 4+ modular units ($800–$15,000/set) | 100% | ≤2h | Not reported | $800 | Yes (voltage/current specs) |

| Strong Power Electric Co.,Ltd. | 3P4W Active Filters, Shunt Harmonic Solutions | 3 specialized units ($1,000–$3,000/unit) | 100% | ≤5h | <15% | $1,000 | Yes (multi-unit configurations) |

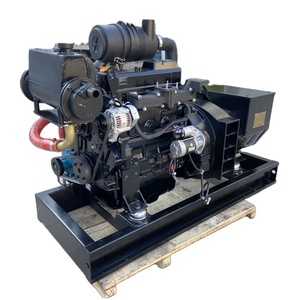

| Fujian Zfly Power Generation Co., Ltd. | Three-phase generators, portable power units | 5 generator-based systems ($220–$4,000/unit) | 100% | ≤18h | 50% | $220 | Extensive (fuel type, phase, cooling, etc.) |

| Jinan Rongda Power Equipment Co., Ltd. | Diesel generators (3-phase output), soundproof plants | 4 power generation units ($900–$5,000/unit) | 100% | ≤4h | <15% | $900 | Basic (enclosure, control panel) |

Performance Analysis

Zhejiang Nengrong and Anhui Zhongdian specialize in advanced power quality solutions such as SVGs and active harmonic filters tailored for 3 phase 3 wire and 4 wire networks, offering robust technical performance and fast response times. Strong Power Electric stands out for its focus on 3P4W active filtering systems, catering to nonlinear load environments like data centers and manufacturing plants. Fujian Zfly and Jinan Rongda provide three-phase power sources (generators) that serve as upstream inputs for 3P3W/3P4W systems, with Zfly demonstrating strong customization flexibility and a high reorder rate indicating customer retention. While most suppliers guarantee 100% on-time delivery, response speed varies significantly—prioritize those with sub-5-hour average replies for time-sensitive projects.

FAQs

How to verify 3 phase system supplier reliability?

Validate technical claims through third-party test reports (e.g., THD reduction from 25% to <5%). Check consistency between declared production capabilities and actual order fulfillment history. Review customer feedback focusing on after-sales support, documentation clarity, and long-term system stability.

What is the typical MOQ and pricing range?

Standard minimum order quantities start at 1 unit/set, with prices ranging from $800 for compact capacitor banks to over $15,000 for high-capacity SVG systems. Some suppliers require bulk orders (e.g., 5 units) for lower-tier pricing on enclosures or auxiliary components.

Are customization options available for 3P3W and 3P4W configurations?

Yes, many suppliers offer configuration flexibility for voltage (380V, 400V, 480V), frequency (50/60Hz), control algorithms, and communication interfaces (RS485, Modbus). Custom enclosures, cooling methods, and integration with existing SCADA systems are also supported upon request.

What are common lead times for samples and bulk orders?

Sample units typically ship within 15–25 days after confirmation. Bulk production lead times range from 30–45 days depending on complexity and order size. Expedited processing may reduce timelines by 7–10 days for urgent deployments.

Do suppliers support global shipping and export documentation?

Established manufacturers routinely handle international shipments with FOB or CIF terms. They provide essential export documentation including packing lists, commercial invoices, and certificates of origin. For regulated markets, confirm availability of CE, RoHS, or country-specific conformity declarations prior to order placement.