3 Phase Controlled Rectifier Pdf

TR

TR

CN

CN

About 3 phase controlled rectifier pdf

Where to Find 3 Phase Controlled Rectifier Suppliers?

China remains the dominant hub for manufacturing 3 phase controlled rectifiers, with key production clusters in Henan, Jiangsu, and Hunan provinces. These regions host vertically integrated facilities specializing in power electronics, industrial rectification systems, and electroplating equipment. Zhengzhou in Henan and Wuxi in Jiangsu are particularly notable for concentrated expertise in silicon-controlled rectifier (SCR) technology and high-current DC power supplies, supporting applications in metal plating, anodizing, and industrial heating.

Suppliers in these zones benefit from proximity to semiconductor foundries, copper processing plants, and transformer manufacturers, enabling tighter control over component sourcing and assembly. This integration reduces lead times by up to 25% compared to decentralized supply chains. Production capabilities range from compact 24V/25A units for laboratory use to industrial-grade systems rated at 70V/40kA, reflecting scalable engineering infrastructure. Buyers gain access to a mature ecosystem where design, prototyping, and volume production occur within coordinated industrial networks.

How to Choose 3 Phase Controlled Rectifier Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Validation

Confirm adherence to international electrical safety standards such as IEC 60950 or IEC 62109 for power conversion equipment. For export markets, CE marking and RoHS compliance are essential for regulatory clearance. Request detailed schematics, cooling specifications, and control interface documentation (e.g., analog/digital feedback loops, PLC integration). Verify whether products utilize phase-angle SCR control or PWM-based switching topologies, as this impacts efficiency and ripple performance.

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area of 2,000m² indicating capacity for full assembly lines

- In-house PCB fabrication, heat sink machining, and busbar forming capabilities

- Dedicated testing bays with load banks capable of validating full-rated output

- Use of flame-retardant enclosures and IP20 or higher protection ratings

Cross-reference supplier claims with on-time delivery rates exceeding 97% and response times under 8 hours to assess operational responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with documented quality management systems—ISO 9001 certification is a baseline indicator. Conduct sample testing to verify voltage regulation accuracy (±1% typical), current stability, and thermal performance under continuous load. Inspect build quality, including terminal insulation, airflow design, and labeling clarity.

What Are the Leading 3 Phase Controlled Rectifier Suppliers?

| Company Name | Location | Main Products | Output Range | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

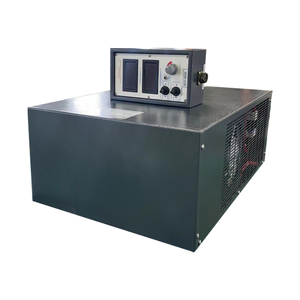

| Zhengzhou Liyuanhaina Rectifier Co., Ltd | Henan, CN | Industrial Power Supplies, Metal Electroplating Machinery | 20V–80V / 1500A–40kA | 1–5 pcs | 100% | ≤4h | - | - |

| SERVO-MATIK Elektronik Sistemler Sanayi Ve Ticaret Limited Sirketi | Istanbul, TR | Rectifiers, UPS, Voltage Regulators | 12V–110V / 25A–100A | 1–5 units | - | ≤8h | - | - |

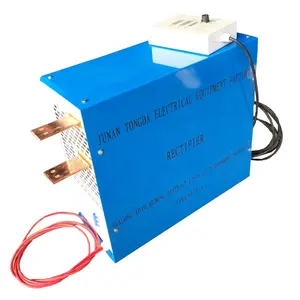

| Wuxi Kenuo Environmental Protection Equipment Co., Ltd. | Jiangsu, CN | Metal Electroplating Machinery, Switching Power Supply | 12V–40V / 1500A–5000A | 1 set | 100% | ≤5h | <15% | US $10,000+ |

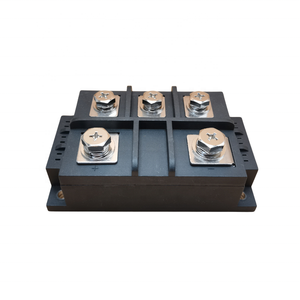

| Zhejiang Duken Electric Co., Ltd | Zhejiang, CN | Thyristors, Diodes, Semiconductor Modules | Module-level components to 3000A systems | 4–10 pcs | 100% | ≤5h | <15% | US $140,000+ |

| Liuyang Haney Electromechanical Equipment Co., Ltd. | Hunan, CN | Metal Electroplating Machinery, Switching Power Supply | Ac-Dc 1500amp and below | 1 piece | 100% | ≤4h | 16% | US $110,000+ |

Performance Analysis

Zhengzhou Liyuanhaina and Liuyang Haney offer high-power solutions suitable for heavy industrial processes, with verified delivery reliability and fast communication cycles. Wuxi Kenuo specializes in electroplating-grade rectifiers with precise voltage/current control, backed by consistent on-time fulfillment. Zhejiang Duken stands out for component-level expertise, supplying SCR modules that enable OEMs to build custom rectification systems. Turkish-based SERVO-MATIK provides cost-effective low-to-mid power units, expanding geographic sourcing options for European buyers seeking regional support. Suppliers with online revenue exceeding US $100,000 demonstrate proven export experience and customer acquisition capability.

FAQs

What certifications should a reliable 3 phase controlled rectifier supplier have?

Look for ISO 9001 certification as evidence of structured quality management. For international shipments, confirm CE marking and compliance with local electrical codes (e.g., UL, CCC, or GOST). Component-level certifications like RoHS ensure environmental compliance, particularly for automated assembly environments.

What is the typical MOQ and lead time?

Standard MOQ ranges from 1 to 5 units depending on power rating. Low-voltage models (e.g., 24V/25A) may ship within 7–10 days, while high-current systems (above 2000A) require 25–35 days for production and testing. Custom configurations can extend lead times to 45 days.

Can suppliers provide technical drawings and operating manuals in English?

Reputable manufacturers typically offer product datasheets, circuit diagrams, and user guides in English. Confirm availability of PDF documentation covering installation, maintenance, and fault diagnostics prior to order placement.

Is customization available for voltage, current, or enclosure type?

Yes, most suppliers support tailored output specifications, digital/analog control interfaces, remote monitoring, and NEMA/IP-rated enclosures. Submit detailed technical requirements early in the procurement cycle to enable feasibility assessment.

How are large rectifiers packaged and shipped internationally?

High-power units are crated with shock-absorbing materials and moisture barriers. Shipping terms are typically FOB or CIF, with sea freight recommended for units over 100kg. Confirm packaging dimensions and gross weight for logistics planning.