3 Phase Distribution Board Explained

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

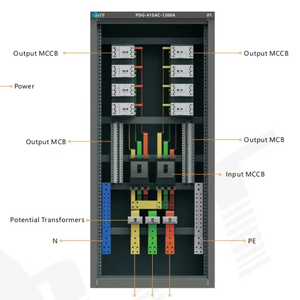

About 3 phase distribution board explained

Where to Find 3 Phase Distribution Board Suppliers?

China remains a dominant force in the production of low-voltage power distribution equipment, with key manufacturing clusters located across Zhejiang, Anhui, Henan, and Sichuan provinces. These regions host vertically integrated facilities specializing in switchgear, control panels, and modular distribution systems, enabling cost efficiencies of 20–35% compared to Western manufacturers. Proximity to raw material sources—such as copper, galvanized iron, and insulating polymers—reduces input costs and supports rapid prototyping and high-volume output.

The industrial ecosystems in these zones integrate component suppliers, sheet metal fabrication units, and electrical testing labs within compact logistical footprints. This co-location enables streamlined production cycles, with standard 3 phase distribution boards typically manufactured within 15–25 days post-design approval. Buyers benefit from scalable operations capable of fulfilling both small-batch custom orders and container-scale deliveries, supported by established export channels to Europe, Southeast Asia, Africa, and the Middle East.

How to Choose 3 Phase Distribution Board Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international standards such as IEC 61439-1 for low-voltage switchgear and controlgear assemblies. For markets requiring regulatory alignment, CE marking, CCC certification (for domestic Chinese use), or RoHS compliance should be verified through official documentation. Evaluate design proficiency by requesting single-line diagrams, busbar layout drawings, and enclosure IP ratings (typically IP54 or higher for outdoor applications).

Production Infrastructure Assessment

Prioritize suppliers with documented engineering capabilities and in-house manufacturing control:

- Sheet metal processing lines including CNC punching, bending, and welding

- In-house assembly lines with torque-controlled fastening tools

- Integration of certified components (e.g., ABB, Schneider, or Siemens breakers) upon request

- Dedicated quality inspection stations for dielectric testing and continuity checks

Cross-reference facility claims with on-time delivery performance; a rate exceeding 95% indicates reliable logistics management.

Customization and Transaction Security

Most leading suppliers support customization of breaker configuration, cable entry points, metering integration, color coding, labeling, and enclosure dimensions. Ensure clear contractual terms for prototype validation before mass production. Utilize secure payment mechanisms with milestone-based releases, particularly for large capital orders. Pre-shipment inspections—either third-party or buyer-conducted—are recommended to verify build quality and component authenticity.

What Are the Leading 3 Phase Distribution Board Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order Value | Key Strengths |

|---|---|---|---|---|---|---|---|

| Anhui Zhongdian Electric Co., Ltd. | Power Distribution Equipment, MV&HV Switchgear, Capacitors | 100% | ≤2h | - | Yes | $1,000/set | High voltage expertise, full substation solutions, responsive communication |

| Zhejiang Hangya Electric Co., Ltd. | MV&HV Switchgear, Power Distribution Equipment, Transformers | 100% | ≤4h | - | Limited | $1,270/set | High protection level enclosures, withdrawable designs, robust construction |

| Henan Longjian Electric Power Equipment Co., Ltd. | Power Distribution Panels, ATS Switchgear, LV Control Panels | 100% | ≤3h | 20% | Extensive (color, size, labels, drawings) | $600/set | OEM/ODM support, flexible MOQs, strong customization |

| Orient Tech Limited | Power Distribution Equipment, Extension Cords, Plugs & Sockets | 91% | ≤3h | 34% | Yes (cable length, monitoring, overload protection) | Not specified | High reorder rate, diversified product range, consistent delivery |

| Chengdu Youlike Electric Co., Ltd. | Power Distribution Equipment | 100% | ≤3h | <15% | Basic configurations | $7.11/10 pcs | Low-cost entry-level boards, high volume pricing, fast turnaround |

Performance Analysis

Anhui Zhongdian and Zhejiang Hangya demonstrate strong technical specialization in medium- and high-voltage compatible distribution systems, making them suitable for industrial and infrastructure projects. Henan Longjian stands out for customization flexibility and OEM capabilities at competitive price points, ideal for buyers seeking branded panel solutions. Orient Tech shows a mature customer retention profile (34% reorder rate), indicating satisfaction in after-sales service and supply consistency. Chengdu Youlike offers the lowest entry cost, targeting budget-conscious buyers for residential or light commercial installations where full system integration is not required.

FAQs

What certifications should a 3 phase distribution board supplier have?

Essential certifications include ISO 9001 for quality management and compliance with IEC 61439-1. Depending on the target market, CE, CCC, or KEMA certification may also be required. Always request test reports for insulation resistance, temperature rise, and short-circuit withstand capability.

What is the typical lead time for custom 3 phase distribution boards?

Standard orders take 15–25 days. Customized units with specific breaker arrangements, metering, or communication interfaces require 25–40 days, depending on design complexity and component availability.

Can suppliers provide single-line diagrams and technical drawings?

Yes, most professional manufacturers offer free preliminary drawings upon request. Final designs are typically approved by the buyer prior to production, ensuring alignment with site-specific electrical requirements.

What are common materials used in 3 phase distribution board enclosures?

Enclosures are commonly fabricated from cold-rolled steel (SPCC) with powder-coated finishes, stainless steel for corrosive environments, or polycarbonate for indoor/light-duty use. Busbars are typically tinned copper or aluminum, rated for continuous current up to 6300A.

How do MOQ and pricing structures vary among suppliers?

MOQs range from 1 set for engineered systems (priced at $600–$15,000/set) to 10-piece batches for standardized enclosures ($7–$35/unit). Volume discounts apply beyond 50 units, with further savings possible through container consolidation for multi-product shipments.