3 Phase Ground Fault Detection

1/2

1/2

CN

CN

1/16

1/16

1/8

1/8

About 3 phase ground fault detection

Where to Find 3 Phase Ground Fault Detection Suppliers?

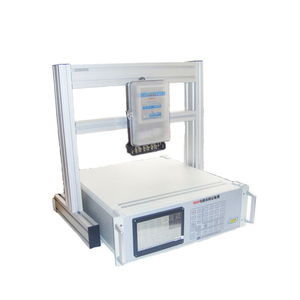

China leads global production of 3 phase ground fault detection systems, with key manufacturing clusters in Guangdong, Jiangsu, and Chongqing enabling specialized electrical safety equipment output. These regions host vertically integrated facilities combining R&D, PCB assembly, and final testing under one roof, supporting rapid prototyping and scalable production. Zhuhai and Shenzhen specialize in intelligent monitoring relays and high-voltage testers, leveraging proximity to semiconductor and sensor suppliers for component consistency. Nanjing and Shanghai focus on industrial-grade protection relays and multifunction test sets, benefiting from established power systems engineering talent pools.

The ecosystem supports diverse product tiers—from basic clamp-type detectors to programmable microprocessor-based units—enabling buyers to align specifications with cost targets. Suppliers report monthly outputs ranging from 500 to 5,000 units depending on complexity, with lead times averaging 15–25 days for standard configurations. Localized supply chains reduce material costs by 18–25% compared to non-Asian manufacturers, while export-ready packaging and multilingual technical documentation ensure compliance across North American, European, and APAC markets.

How to Choose 3 Phase Ground Fault Detection Suppliers?

Implement structured evaluation criteria to mitigate sourcing risks:

Technical Compliance

Verify adherence to IEC 61557-9 (insulation monitoring), IEC 60255 (protection relays), and IEC 61010-1 (safety requirements for electrical test equipment). For installations in hazardous or industrial environments, confirm IP65+ ingress protection ratings and operating temperature ranges of -25°C to +70°C. Request calibration certificates traceable to national standards (e.g., NIST, CNAS) for test instruments.

Production Capability Audits

Assess operational scale and control systems:

- Minimum 2,000m² dedicated production area for consistent batch output

- In-house testing labs with dielectric strength, thermal cycling, and EMI/EMC validation capabilities

- Surface-mount technology (SMT) lines for PCB assembly to ensure long-term reliability

Cross-reference online revenue metrics with on-time delivery performance (target ≥98%) to validate order fulfillment capacity.

Transaction Safeguards

Utilize secure payment methods with milestone verification, particularly for custom-developed units. Prioritize suppliers offering sample validation before bulk orders, and request firmware version logs for digital devices. Confirm packaging integrity for shock-sensitive instruments and verify inclusion of user manuals, test reports, and software tools for configuration.

What Are the Best 3 Phase Ground Fault Detection Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhuhai Yuandian Electric Technology Co., Ltd. | Alarm Systems, Power Distribution Equipment, MV&HV Switchgear | US $2,000+ | 100% | ≤7h | - | No data | 1 piece/set | $40.63–$479 |

| Shenzhen Meiruike Electronic Technology Co., Ltd. | Testing Equipment, Resistance Meters, Voltage Meters | US $5,000+ | 100% | ≤2h | <15% | No data | 1 pack/piece/set | $90–$4,200 |

| Nanjing Zhuneng Electric Co., Ltd. | Customization Available | US $10,000+ | 100% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | 1 set | $289–$1,500 |

| Rui Du Electromechanical (Shanghai) Limited Company | Testing Equipment, Battery Testers, Multimeters | US $120,000+ | 100% | ≤2h | 50% | No data | 1 set | $77–$3,375 |

| Chongqing Blue Jay Technology Co., Ltd. | Relays, Energy Meters, Resistance Meters | US $10,000+ | 100% | ≤7h | 20% | No data | 1–10 pieces | $50–$180 |

Performance Analysis

Rui Du Electromechanical stands out with the highest reorder rate (50%) and substantial transaction volume, indicating strong customer retention and market trust. Nanjing Zhuneng offers full customization options, making it ideal for OEM integration or branded deployments. Shenzhen Meiruike and Rui Du lead in responsiveness (≤2h average), critical for urgent technical clarifications. Zhuhai Yuandian provides entry-level pricing from $40.63 per unit, suitable for cost-sensitive deployments. All top-tier suppliers maintain 100% on-time delivery records, underscoring reliability in logistics execution. Buyers seeking advanced programmable testers should prioritize suppliers offering documentation for RK9950C or MiCOM-class devices.

FAQs

How to verify 3 phase ground fault detection supplier reliability?

Validate technical claims through independent lab reports and firmware verification. Check for consistent product coding, serial traceability, and conformity marks. Analyze transaction history for dispute patterns and confirm after-sales support availability for calibration or firmware updates.

What is the typical sampling timeline?

Standard samples ship within 7–14 days. For customized units requiring firmware modification or housing adjustments, allow 20–30 days. Express shipping adds 3–7 days for international delivery.

Can suppliers provide certified calibration?

Yes, leading suppliers issue出厂检验证明 (factory inspection certificates) and can provide third-party CNAS-accredited calibration upon request. Ensure certification includes voltage accuracy, trip time tolerance, and insulation resistance benchmarks.

Do suppliers support low-volume or single-unit orders?

Most suppliers accept MOQs of 1 piece or set, particularly for handheld testers and relay modules. However, unit prices decrease significantly at 5+ and 10+ quantities, especially for relay and sensor-based products.

How to initiate customization for ground fault detection units?

Submit detailed requirements including rated voltage (e.g., 380VAC, 10kV), communication interface (RS485, CAN, Ethernet), trip threshold range, and enclosure material. Suppliers with SMT and injection molding capabilities can integrate custom labels, branding, and mechanical dimensions within four weeks.