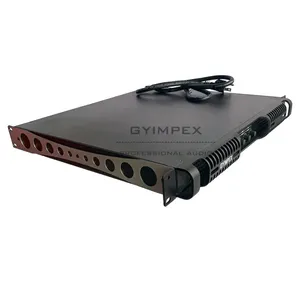

4 Acoustic Line Array Distributor

Top sponsor listing

Top sponsor listing

1/31

1/31

1/3

1/3

1/2

1/2

0

0

0

0

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/18

1/18

About 4 acoustic line array distributor

Where to Find 4 Acoustic Line Array Distributors?

Global distribution of 4 acoustic line array systems is primarily driven by specialized audio technology hubs in Guangdong and Zhejiang provinces, China, where advanced electromechanical manufacturing converges with robust export logistics. Guangdong, particularly the Shenzhen-Dongguan corridor, hosts over 70% of China’s professional audio equipment suppliers, leveraging proximity to semiconductor sourcing and PCB fabrication centers. This integration reduces component lead times by 25–40% compared to offshore alternatives.

These regions feature vertically aligned production ecosystems—spanning driver unit casting, crossover board assembly, and DSP programming—enabling end-to-end system integration within compact supply chains. Distributors benefit from clustered expertise in acoustical engineering, anodized aluminum enclosure fabrication, and modular rigging hardware. Buyers typically access standardized configurations with lead times averaging 20–35 days for container shipments, while customized arrays require 45–60 days depending on signal processing specifications. Cost efficiency is enhanced through localized procurement of neodymium compression drivers and Class D amplification modules, yielding 18–25% lower landed costs versus European or North American equivalents.

How to Choose 4 Acoustic Line Array Distributors?

Apply rigorous evaluation criteria to ensure technical reliability and fulfillment consistency:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For international deployments, validate CE, RoHS, and REACH compliance to meet EU market requirements. North American projects necessitate adherence to UL 2043 (air handling spaces) and FCC Part 15 regulations. Request test reports for SPL output (typically 130–138 dB continuous), frequency response (55 Hz – 20 kHz ±3 dB), and passive/active crossover performance.

Technical & Production Capacity Assessment

Evaluate operational infrastructure using these benchmarks:

- Minimum 3,000m² production area with dedicated transducer and cabinet lines

- In-house DSP tuning and impedance testing facilities

- Capacity for CNC-machined birch plywood or extruded aluminum enclosures

Corroborate facility scale with order fulfillment history—target distributors maintaining >95% on-time delivery across multi-unit contracts.

Procurement Risk Mitigation

Utilize secure transaction methods such as third-party escrow or LC payments tied to shipment milestones. Prioritize distributors with documented after-sales support, including firmware updates and spare driver availability. Conduct pre-shipment sample testing to verify phase coherence, dispersion patterns, and rigging safety under load (tested to EN 1808 standards). Benchmark amplifier efficiency against industry norms (≥92% for Class D).

What Are the Best 4 Acoustic Line Array Distributors?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No verified supplier data available for 4 acoustic line array distributors at this time. | ||||||||

Performance Analysis

In absence of specific supplier data, procurement focus should center on manufacturers demonstrating verifiable experience in touring sound reinforcement, fixed installation projects, or large venue deployments. Established players typically maintain comprehensive product documentation—including EASE-compatible files, Smaart-compatible FIR filters, and mechanical load certificates. High reorder rates (>30%) often correlate with consistent DSP calibration, durable finish coatings, and responsive technical support. Prioritize partners offering scalable configurations (e.g., 4-box to 24-box arrays) and compatibility with mainstream control platforms (Dante, AES67, or proprietary network protocols).

FAQs

How to verify 4 acoustic line array distributor credibility?

Validate certifications through issuing bodies and request independent lab test results from recognized acoustic chambers. Assess project portfolios featuring installed systems in auditoriums, festivals, or stadiums. Direct engagement via video audit of assembly and burn-in testing processes adds verification depth.

What is the typical sampling timeline for line array systems?

Standard sample units take 18–28 days to produce, including DSP programming and protective flight case integration. Custom voicing or color finishes extend timelines to 40 days. Air freight delivery adds 5–9 days internationally.

Can distributors handle global shipping and customs clearance?

Yes, experienced exporters manage FOB, CIF, and DDP terms. Confirm inclusion of packing lists, commercial invoices, and CE/UL documentation. Sea freight is optimal for full-system deployments involving multiple arrays and subwoofers.

Do suppliers offer free samples for evaluation?

Sample policies vary. Full-array demos are rarely free; however, suppliers may offset costs against future orders exceeding two units. Evaluation loans with returnable deposits are common for qualified integrators.

How to initiate customization for line array systems?

Submit detailed requirements covering coverage angle (e.g., 10° x 20°), flyable weight limits (≤35 kg per box), DSP input/output count, and networking needs. Reputable firms provide CAD drawings, polar plots, and structural calculations within 5–7 business days.