5 Uses Of Plotter

About 5 uses of plotter

Where to Find Plotter Suppliers?

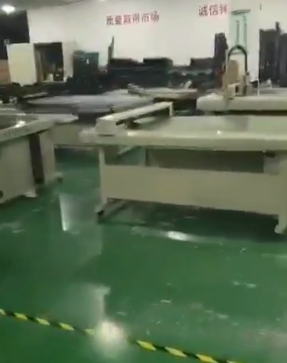

China remains a dominant hub for plotter manufacturing, with key production clusters in Zhejiang, Guangdong, and Yiwu offering specialized capabilities across different plotter types. These regions host vertically integrated supply chains that support both large-format cutting plotters and precision digital vinyl cutters used in signage, textiles, and marine navigation systems. Industrial zones in Dongguan and Shenzhen focus on high-precision components such as tungsten carbide blades and servo-driven cutter mechanisms, while Yiwu and Ningbo specialize in multifunction combo units integrating heat press and sublimation functions.

The geographic concentration enables efficient component sourcing—steel frames, stepper motors, control boards—from within 50km radii, reducing lead times by up to 25%. Buyers benefit from scalable production models capable of fulfilling orders ranging from single units to container-sized batches. Average lead times range from 15–30 days depending on customization level, with localized logistics networks supporting rapid dispatch via air or sea freight. Cost advantages are significant: Chinese suppliers typically offer 20–40% lower pricing than European or North American manufacturers due to reduced labor and overhead costs.

How to Choose Plotter Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions.

Technical Compliance & Product Range

Verify compatibility with intended applications—vinyl cutting, garment printing, marine chart plotting, or industrial blade replacement. Suppliers should provide clear specifications including cutting force (grams), maximum width (cm/inch), software compatibility (e.g., CorelDRAW, AutoCAD), and driver support. For export markets, CE certification is essential for compliance with electromagnetic and safety standards. Where applicable, confirm GPS module accuracy (±3m) and waterproof ratings (IPX7) for marine plotters.

Production Capability Assessment

Evaluate supplier infrastructure using the following criteria:

- Minimum factory area exceeding 2,000m² for stable output

- In-house R&D or engineering teams for custom modifications

- Integration of CNC machining, laser calibration, and automated testing lines

Cross-reference online revenue data (US$30,000–240,000+) and reorder rates (<15% to 20%) to assess market trust and product reliability.

Transaction Risk Mitigation

Prioritize suppliers with documented quality control processes and responsive communication (response time ≤9 hours). Use secure payment methods such as escrow services to ensure delivery verification before fund release. Request sample units to validate build quality, especially for blade holders and dual-function combo machines. Confirm minimum order quantities (MOQs), which often start at 1 piece for standard plotters but may require 10+ pieces for consumables like cutting blades.

What Are the Best Plotter Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Examples | Price Range (Min. Order) |

|---|---|---|---|---|---|---|---|

| Yiwu Kaimai Machinery Equipment Factory | Heat Press Machine (599), Tumblers, Transfer Machines | US $30,000+ | 97% | ≤7h | 20% | Multifunction Sublimation Plotters, A5 Cutters | $160–279 (1 piece) |

| Yiwu Rubysub Digital Graphic Co., Ltd. | Decorative Objects, Heat Press Machines | US $150,000+ | 97% | ≤6h | 16% | 5-in-1 Combo Plotters, Desktop Vinyl Cutters | $171–270 (1 set) |

| Dongguan Frontier Precision Ltd | Industrial Blades, Mower Parts, Saw Components | US $240,000+ | 91% | ≤9h | <15% | Cutting Blades, Blade Holders, Carbide Tips | $0.40–5.80 (10 pieces) |

| Dongtai Winbay Marine Safety Equipment Co., LTD. | Marine Supplies, GPS Chartplotters, Radar Systems | US $30,000+ | 96% | ≤6h | <15% | Marine Navigation Plotters, 5-Inch GPS Units | $280–950 (1 set) |

| Shenzhen Shenhuayang Electronic Technology Co., Ltd. | Navigation & GPS, Marine Electronics | US $60,000+ | 100% | ≤9h | <15% | ONWA KM Series, Xinuo XF-520 Marine Plotters | $135–700 (1–10 sets) |

Performance Analysis

Yiwu-based suppliers excel in multi-functional plotters combined with heat transfer systems, targeting small businesses in apparel decoration. Their higher reorder rate (20%) indicates strong customer retention in niche DIY and craft markets. In contrast, Dongguan Frontier Precision focuses on consumable components like cutting blades, serving industrial users requiring high wear resistance and precision tolerances (±0.01mm). Shenzhen and Dongtai-based firms dominate marine-grade plotters, offering ruggedized GPS-enabled devices compliant with maritime environmental standards. Notably, Shenzhen Shenhuayang achieves perfect on-time delivery (100%), suggesting robust internal logistics despite lower reorder frequency. Buyers seeking cost-effective blade replacements should prioritize bulk procurement from Dongguan suppliers, while those needing integrated design-to-cut workflows can leverage Yiwu’s combo machine ecosystem.

FAQs

What are the 5 common uses of a plotter?

Plotters serve multiple industrial and commercial functions: (1) Vinyl cutting for vehicle wraps and signage, (2) Garment sublimation using combo heat press systems, (3) Precision cutting of stickers, decals, and lettering films, (4) Marine navigation via GPS-enabled chartplotters displaying real-time sonar and route tracking, and (5) Production of spare parts such as cutting blades and blade holders for maintenance of existing plotter fleets.

What is the typical MOQ for plotters?

Standard plotters and machines usually have an MOQ of 1 unit or set. However, consumables like cutting blades and holders often require minimum purchases of 10 pieces. Bulk discounts apply at 50+ units, particularly for exporters consolidating container loads.

Are plotters CE certified?

Most export-oriented suppliers declare CE compliance for electrical safety and EMC directives. Buyers should request test reports or certification documents directly, especially for powered equipment shipped to EU or UK markets. Marine plotters may also include additional IP and RoHS certifications.

Can I customize plotter functionality?

Yes, many suppliers offer OEM/ODM services including logo branding, voltage adjustments (110V/220V), software interface localization, and mechanical modifications such as extended cutting beds. Lead time for customized units increases by 7–14 days compared to stock models.

How long does shipping take internationally?

Air freight delivers samples within 5–10 days globally. Sea freight for full orders takes 25–40 days depending on destination port and customs procedures. FOB terms are standard; buyers assume responsibility post-loading. Insurance and import duties remain the recipient’s obligation.