7 Types Of Robots With Examples

1/5

1/5

1/14

1/14

1/17

1/17

1/11

1/11

1/23

1/23

CN

CN

1/12

1/12

1/18

1/18

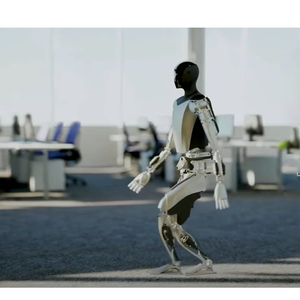

About 7 types of robots with examples

Where to Find Suppliers for 7 Types of Robots with Examples?

The global supplier base for robotic systems categorized under "7 types of robots with examples" spans industrial automation, educational technology, and consumer electronics manufacturing hubs, with a significant concentration in Eastern China. Key production clusters in Shanghai, Shantou, and Zhengzhou offer specialized capabilities across payload capacity, degrees of freedom (DOF), and application-specific design. These regions host vertically integrated supply chains—from precision machining to AI integration—enabling rapid prototyping and scalable production. Proximity to component suppliers reduces lead times by 20–30% compared to offshore alternatives, while established logistics corridors support efficient export fulfillment.

Suppliers in this sector operate within distinct niches: industrial robot arms (6-axis and 7-axis configurations), humanoid robotics, mobile security platforms, and educational or toy-based programmable units. Regional specialization enables buyers to align procurement strategies with technical requirements, whether sourcing high-payload collaborative robots or low-cost interactive models for STEM applications. Economies of scale are evident in facilities reporting monthly outputs exceeding 500 units, supported by in-house R&D teams focused on motion control, sensor integration, and AI behavior modeling.

How to Choose Suppliers for 7 Types of Robots with Examples?

Selecting reliable suppliers requires adherence to structured evaluation criteria across technical, operational, and transactional dimensions:

Technical & Functional Verification

Confirm alignment between product specifications and intended use cases. Industrial-grade robotic arms (e.g., 6-axis or 7-axis models) should list precise payload ratings (typically 3–18 kg), repeatability tolerances (±0.02 mm standard), and controller compatibility (e.g., Yaskawa GP-series integration). For humanoid or AI-driven units, validate onboard processing capabilities, battery life, and software development kit (SDK) availability for customization. Request performance test reports for dynamic load testing and cycle durability.

Production and Customization Capacity

Assess infrastructure maturity through the following indicators:

- Minimum factory area of 3,000m² for industrial robotics producers

- In-house CNC, welding, and assembly lines to ensure quality traceability

- Customization options including color, material (ABS/plastic/metal alloys), gripper configuration, and branding elements

Cross-reference stated capabilities with order fulfillment metrics such as on-time delivery rates (target ≥93%) and response time benchmarks (≤7 hours).

Quality Assurance and Compliance

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not universally listed, its presence indicates standardized process controls. For consumer-facing robotic toys, verify compliance with safety standards such as ASTM F963 (U.S.) or EN 71 (EU). Electromagnetic compatibility (EMC) and RoHS directives apply to all electronic components. Third-party inspection services should be available upon request, particularly for bulk orders.

Transaction Security and After-Sales Support

Utilize secure payment mechanisms like escrow where possible. Analyze reorder rates as an indicator of customer satisfaction—values above 20% suggest strong post-sale reliability. Evaluate responsiveness (measured in average reply time) and technical support depth, especially for complex deployments requiring integration assistance or firmware updates.

What Are the Leading Suppliers for 7 Types of Robots with Examples?

| Company Name | Specialization | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|---|---|

| Xiangjing (Shanghai) Mechanical and Electrical Tech Co., Ltd. | Industrial Robotic Arms | 6-axis, 7-axis arms (Yaskawa-compatible) | $12,000–28,818 | 1 set | 100% | ≤7h | 20% | $50K+ |

| Story Enterprise Limited | Humanoid & AI Robots | H1/G1 humanoids, smart pet robots | $60–89,900 | 1 set | 93% | ≤3h | <15% | $50K+ |

| Zhengzhou Defy Mechanical & Electrical Equipment Co., Ltd. | Autonomous Patrol Robots | Security, inspection, mobile chassis | $4,580–20,000 | 1 set | 100% | ≤4h | - | $50K+ |

| Shantou Capable Toys Co., Ltd. | Educational & RC Robots | Programming dogs, gesture-sensing units | $4.69–16.98 | 40–80 pcs/sets | 100% | ≤6h | <15% | $50K+ |

| Shantou Beilisi Toys Co., Ltd. | Transforming Robot Toys | ABS deformation cars, morphing robots | $0.84–2.88 | 5–360 units | 100% | ≤1h | <15% | $10K+ |

Performance Analysis

Xiangjing (Shanghai) stands out for industrial automation needs, offering high-precision multi-axis robotic arms with competitive pricing and proven delivery consistency. Story Enterprise Limited provides access to advanced humanoid platforms, including H1 and G1 models, though lower reorder rates suggest potential gaps in long-term support. Zhengzhou Defy specializes in commercial service robots with autonomous navigation, ideal for security and inspection applications requiring ruggedized designs. On the consumer side, Shantou-based suppliers dominate low-cost programmable and transforming robots, with Beilisi achieving sub-hour response times, indicating robust customer service infrastructure. Capable Toys offers mid-tier programmable robotics suitable for STEM education markets, with customization flexibility in packaging and branding.

FAQs

How to verify robot supplier reliability?

Cross-check technical documentation against actual product listings. Request evidence of quality control processes, such as final assembly testing logs or material certifications. Analyze verifiable buyer feedback focusing on defect rates, software stability, and technical support responsiveness.

What is the typical lead time for robot samples?

Standard sample lead times range from 10–20 days for pre-configured models. Customized units (e.g., modified payloads, SDK integrations) may require 30–45 days depending on engineering workload. Air shipping adds 5–10 days for international delivery.

Can suppliers accommodate custom programming or AI training?

Limited providers offer SDK access or API integration for behavioral customization. Confirm software architecture (ROS compatibility preferred) and inquire about firmware update protocols. Most toy-grade robots have fixed functionality, while industrial and humanoid units may support user-defined scripting.

Do manufacturers provide free samples?

Free samples are uncommon for high-value robotics (>$1,000). For lower-cost units, suppliers may waive fees contingent on future bulk orders (e.g., minimum 500 units). Sample costs typically cover 30–50% of unit price and are non-refundable unless defects are confirmed.

What are standard MOQs and payment terms?

Industrial robots typically require MOQs of 1 set, priced FOB with T/T (30% deposit, 70% before shipment). Consumer robots often have higher volume thresholds (e.g., 360 units) but allow smaller trial orders. Trade Assurance-backed transactions are recommended for first-time engagements.