7 Types Of Waste In Lean Manufacturing With Examples

CN

CN

CN

CN

CN

CN

About 7 types of waste in lean manufacturing with examples

Where to Find Suppliers for Waste Management Equipment in Lean Manufacturing?

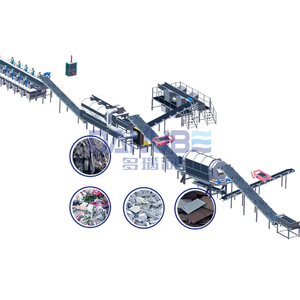

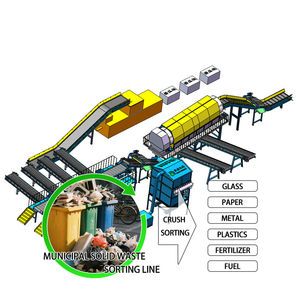

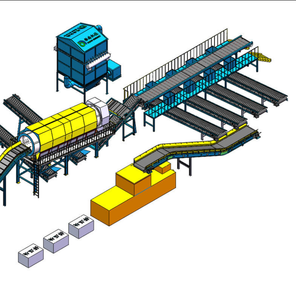

China remains a central hub for industrial waste management machinery, with key manufacturing clusters located in Henan Province and the Pearl River Delta region. Henan hosts multiple specialized producers of waste sorting, recycling, and treatment systems—many integrated within broader construction and agricultural machinery ecosystems. These suppliers benefit from regional supply chain density, including access to steel fabrication, plastic processing, and automation component vendors within 50km radii, enabling cost reductions of 18–25% compared to Western equivalents.

The operational scale of these clusters supports both standardized and engineered-to-order solutions. Facilities commonly feature vertical integration across drying equipment, briquetting lines, carbonization stoves, and AI-powered sorting conveyors. This infrastructure allows lead times of 30–45 days for standard configurations, with bulk production runs prioritized through dedicated assembly zones. Buyers gain flexibility in MOQs ranging from single sets for pilot installations to container-scale orders for municipal deployments.

How to Choose Waste Management Equipment Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international quality standards such as ISO 9001 for design and manufacturing processes. For exports to regulated markets (EU, North America), verify CE marking or equivalent safety certifications on final equipment. Request documentation for critical subsystems—including motors, control panels, and emission systems—to ensure compliance with environmental and operational regulations.

Production and Customization Capability

Assess supplier infrastructure using the following benchmarks:

- Minimum factory area exceeding 5,000m² for scalable output

- In-house engineering teams capable of system customization (e.g., bin capacity, material separation algorithms, PLC controls)

- Integrated machining capabilities: CNC fabrication, welding, and plastic crushing units

Cross-reference online revenue indicators (>US$400,000/year) and reorder rates (>25%) as proxies for market acceptance and reliability.

Transaction Risk Mitigation

Utilize secure payment frameworks that tie disbursements to delivery milestones. Prioritize suppliers with documented response times ≤4 hours and on-time delivery performance ≥97%. Conduct pre-shipment inspections via third-party auditors to validate equipment functionality against agreed specifications. Sampling is strongly advised—benchmark machine throughput, sorting accuracy, and energy consumption before full procurement.

What Are the Leading Waste Management Equipment Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Main Product Focus | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Jiangmen Victory Limited | Guangdong, CN | US $900,000+ | 100% | ≤4h | 26% | Waste bins (6L–60L), indoor trash cans, pedal-operated stainless steel units | Color, shape, size, compartment layout, logo, packaging | 200–500 pieces depending on model |

| Henan New Guoxin Machinery Manufacturing Co., Ltd. | Henan, CN | US $440,000+ | 100% | ≤2h | 33% | Municipal solid waste sorters, recycling lines, waste-to-energy plants | Size, color, material, logo, labeling, graphics | 1 set (customizable) |

| Henan Flysun Machinery Manufacturing Co., Ltd. | Henan, CN | US $200,000+ | 80% | ≤4h | <15% | Waste compactors, plastic recyclers, landfill sorting plants, incinerators | Limited customization reported | 1 set |

| DANUBE MACHINERY EQUIPMENT SINGAPORE PTE LTD | Singapore (Manufacturing in CN) | Data Unavailable | Not Reported | ≤4h | Not Reported | AI-powered sorting systems, construction waste recycling lines, modular treatment plants | Full line customization available | 1–2 sets depending on configuration |

| DANUBE MACHINERY EQUIPMENT (SINGAPORE) PTE. LTD. | Singapore (Manufacturing in CN) | Not Reported | Not Reported | ≤2h | Not Reported | Automatic waste sorters, brick-making from waste, EPC waste disposal machines | OEM and technology-integrated builds | 1 set minimum |

Performance Analysis

Jiangmen Victory Limited stands out for high-volume consumer-grade waste containers, offering extensive customization at competitive unit prices ($2.98–$34.85). With a 100% on-time delivery rate and robust reorder volume, it serves buyers seeking branded or retail-ready products. Henan New Guoxin demonstrates strong technical responsiveness and customer retention (33% reorder rate), making it suitable for municipal and industrial clients requiring certified recycling infrastructure.

Flysun Machinery offers broad product coverage but shows lower repeat business (<15% reorder rate) and an 80% delivery performance, suggesting potential fulfillment risks. The Danube Machinery entities exhibit rapid response times and advanced technological offerings—including AI-driven sorting—but lack verifiable delivery and revenue metrics, increasing due diligence requirements. For mission-critical installations, prioritize suppliers with transparent performance data and established export histories.

FAQs

How to verify supplier reliability for waste management equipment?

Cross-validate ISO or CE certifications with issuing bodies. Request audit reports covering production workflows, material traceability, and QC testing procedures. Analyze buyer reviews focused on post-installation support, spare parts availability, and long-term machine durability.

What are typical MOQs and pricing ranges?

Consumer bins range from $2.98 to $34.85 with MOQs of 200–500 pieces. Industrial systems (sorting lines, compactors, incinerators) start at $18,000 per set with MOQs of 1–2 sets. High-end AI-powered systems can exceed $138,000 per unit.

Do suppliers support customization?

Yes. Most offer adjustments in size, color, material, branding, and functional components. Full OEM projects—including smart sorting algorithms and integrated conveyors—are available from manufacturers like Danube Machinery and Henan New Guoxin.

What is the average lead time for customized systems?

Standard units ship in 30–45 days. Engineered systems with automation or AI integration require 45–60 days, including testing and client review phases.

Can suppliers handle global shipping?

Yes. Established exporters manage FOB and CIF shipments worldwide. Confirm compliance with destination country regulations for electrical systems, emissions, and waste processing technologies. Sea freight is standard for heavy machinery; air freight options exist for urgent component deliveries.