A53 Cortex

1/17

1/17

1/3

1/3

1/3

1/3

0

0

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/5

1/5

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/2

1/2

About a53 cortex

Where to Find A53 Cortex Suppliers?

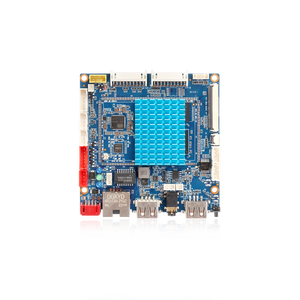

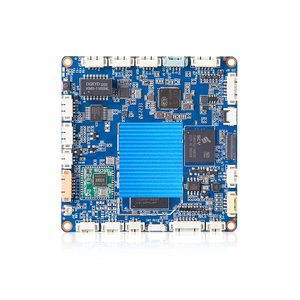

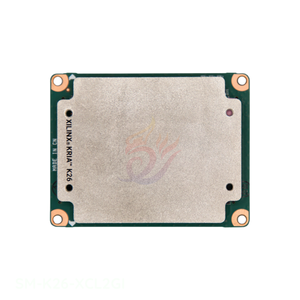

No verified suppliers for A53 Cortex components are currently identified in major industrial manufacturing hubs. Unlike established machinery categories, the A53 Cortex—commonly associated with ARM-based embedded processing units—does not align with traditional heavy equipment supply chains in China or other low-cost manufacturing regions. Production of such technology-intensive components typically occurs within specialized semiconductor and electronics ecosystems, primarily concentrated in East Asia, with key clusters in Taiwan, South Korea, and the Pearl River Delta region of China.

In these regions, vertically integrated electronics manufacturers and contract assemblers support complex printed circuit board (PCB) assembly, surface-mount technology (SMT), and firmware integration required for Cortex-A53 processor deployment. Facilities in Shenzhen and Dongguan, for example, offer rapid prototyping and small-batch production capabilities, supported by dense networks of component distributors, testing labs, and logistics providers. Lead times for sample batches range from 20–40 days depending on customization level, while unit costs benefit from economies of scale in high-volume runs (10,000+ units). However, direct access to original design manufacturers (ODMs) producing A53-based modules requires technical prequalification and compliance verification due to intellectual property and export control considerations.

How to Choose A53 Cortex Suppliers?

Given the absence of listed suppliers, procurement strategies must emphasize technical due diligence and compliance alignment:

Technical Compliance

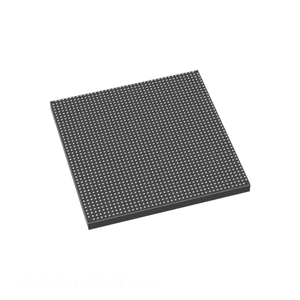

Confirm adherence to ARM architecture licensing requirements and applicable industry standards, including IPC-A-610 for electronic assemblies and ISO 13485 (if used in medical applications). For commercial or industrial deployments, IEC 61508 functional safety certification may be required. Request documentation on thermal performance, power efficiency (typically 0.5–1.5W under load), and supported operating environments (-40°C to +85°C extended range preferred).

Production Capability Audits

Evaluate supplier infrastructure using remote audit protocols:

- Minimum SMT line capacity supporting 0201 package placement and reflow profiling

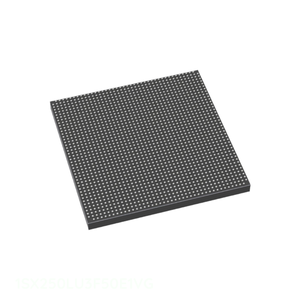

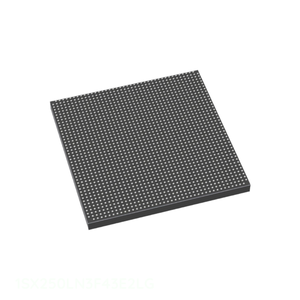

- In-house PCB testing capabilities (ICT, AOI, X-ray inspection for BGA packages)

- Firmware flashing and validation stations for boot verification and OS integration

Verify traceability systems covering lot-controlled components and RoHS compliance through material declarations (e.g., IMDS or IPC-1752).

Transaction Safeguards

Utilize secure payment mechanisms such as irrevocable letters of credit or escrow services tied to milestone deliveries. Prioritize partners with documented export experience to regulated markets (EU, US, Japan), ensuring ECCN classification (e.g., 3A991.b.1) is confirmed for customs clearance. Pre-production sampling is critical—test for CPU clock stability, memory bandwidth, and peripheral interface functionality before scaling orders.

What Are the Best A53 Cortex Suppliers?

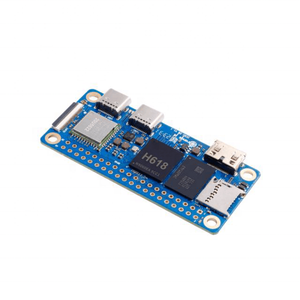

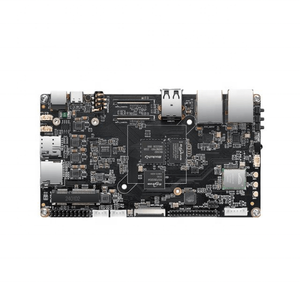

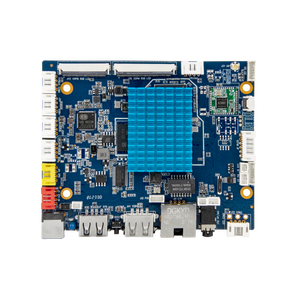

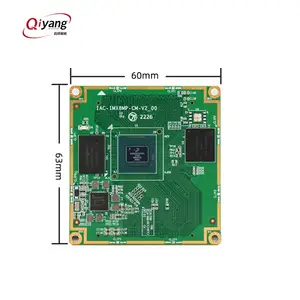

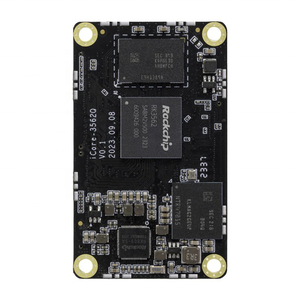

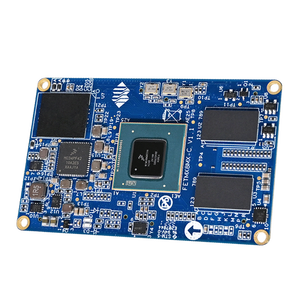

No supplier data is available for entities currently offering A53 Cortex-related products. Market intelligence indicates that most Cortex-A53 implementations are delivered via module-level solutions (e.g., SOMs – System-on-Modules) from established electronics manufacturers rather than standalone processors. These are typically sourced through authorized distributors or OEM partnerships with companies like NXP, Rockchip, or Allwinner, which integrate the Cortex-A53 core into application-specific SoCs.

Performance Analysis

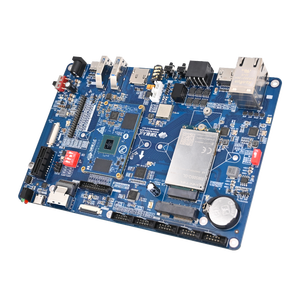

In the absence of direct suppliers, buyers should focus on downstream integrators capable of delivering tested, validated boards with secure boot, Linux/BSP support, and long-term availability (10+ year lifecycle commitments). Preference should be given to firms providing comprehensive SDKs, thermal management designs, and EMI shielding documentation. Procurement success hinges on engaging technically vetted partners who can demonstrate prior deployment in similar use cases—industrial automation, edge computing, or IoT gateways—with verifiable field reliability metrics.

FAQs

How to verify A53 Cortex supplier reliability?

Assess technical credibility through product tear-down reports, third-party benchmarking (e.g., CoreMark/MHz scores), and participation in ARM-approved partner programs. Review firmware update policies, security patch availability, and BOM transparency. Direct engagement via engineering consultations helps validate design-in support capacity.

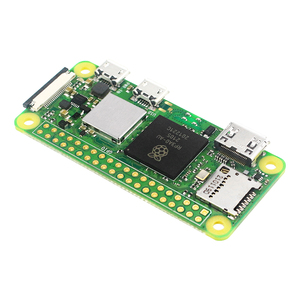

What is the average sampling timeline?

Standard evaluation kits or development boards are typically available within 7–14 days from authorized channels. Custom carrier board designs or modified SOM configurations require 30–50 days, including layout, fabrication, and initial bring-up testing.

Can suppliers ship A53 Cortex components worldwide?

Yes, but shipping depends on export classification and regional restrictions. Ensure suppliers comply with EAR or equivalent regulations and provide proper HTS codes. Air freight remains standard for samples; sea consolidation is viable for large-volume shipments exceeding 500kg.

Do manufacturers provide free samples?

Development boards are often available at discounted rates or through approved developer programs. Full custom modules typically require paid sampling, with costs ranging from $150–$500 per unit, refundable against future orders above specified thresholds.

How to initiate customization requests?

Submit detailed requirements including memory configuration (LPDDR3/LPDDR4), storage type (eMMC/NAND), supported interfaces (USB 3.0, Gigabit Ethernet, MIPI), and environmental specifications. Reputable vendors respond with schematic reviews, layout guidelines, and preliminary thermal models within 5–7 business days.