Aac Block Making Machine

Top sponsor listing

Top sponsor listing

1/7

1/7

1/16

1/16

1/26

1/26

CN

CN

1/29

1/29

1/24

1/24

CN

CN

1/18

1/18

1/27

1/27

About aac block making machine

Where to Find AAC Block Making Machine Suppliers?

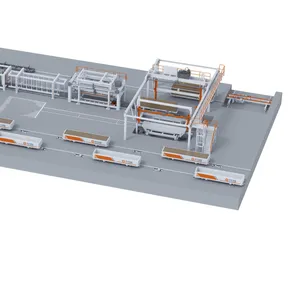

China remains the global epicenter for AAC (Autoclaved Aerated Concrete) block making machine manufacturing, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, precision engineering, and final assembly under one supply chain. Shandong’s Jining and Qingdao zones specialize in fully automated systems, supported by mature steel and hydraulics industries that reduce component costs by 15–20%. Henan, particularly around Zhengzhou, has emerged as a hub for mid-range semi-automatic and modular AAC line solutions, benefiting from dense construction machinery networks and streamlined logistics.

The clustering effect enables suppliers to offer rapid prototyping, scalable production, and competitive pricing. Facilities typically integrate CNC machining, welding automation, and control panel fabrication on-site, allowing lead times of 30–60 days for standard configurations. Buyers gain access to flexible MOQs—from single units to turnkey plant installations—supported by localized technical talent pools and export-ready infrastructure. This concentration also fosters innovation in energy-efficient curing systems and digital control integration, aligning with global demand for sustainable building materials.

How to Choose AAC Block Making Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline indicator of quality management. For exports to regulated markets (EU, North America, GCC), confirm CE marking and compliance with machinery safety directives. Request documentation for critical subsystems—including hydraulic pressure systems, vibration motors, and PLC-based control panels—to ensure durability and process consistency.

Production Capability Assessment

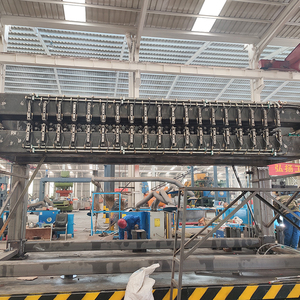

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area of 3,000m² for dedicated AAC equipment lines

- In-house design and R&D teams capable of custom mold development and automation integration

- Integrated testing protocols for mold alignment, pressure tolerance (≥18 MPa), and batching accuracy

Cross-reference online performance data—such as on-time delivery rates exceeding 97%—with product range diversity to assess scalability and order reliability.

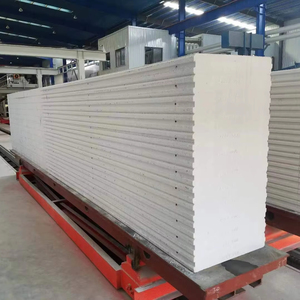

Customization & Process Integration

Confirm capability to customize block formats (e.g., 600×200×100 mm to 600×250×300 mm), production capacity (4–35 m³/h), and automation level (manual feeding to full palletizing robots). Leading suppliers support integration with silo systems, steam curing autoclaves, and conveyor layouts based on site-specific plant designs.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services or letters of credit. Prioritize suppliers with transparent transaction histories, including reorder rates above 20% and response times under 4 hours. Conduct sample validation by requesting test reports on block density (500–800 kg/m³), compressive strength (≥3.5 MPa), and dimensional tolerance (±1.5 mm).

What Are the Best AAC Block Making Machine Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Revenue Tier | Product Range | Automation Level |

|---|---|---|---|---|---|---|---|---|

| Shandong Kaidong Construction Machinery Co., Ltd. | Custom Manufacturer | Brick/Tile/Cement Machinery | 100% | 16% | ≤2h | US $320,000+ | 12+ models | Fully automatic to manual |

| Zhengzhou Yongsi Commercial & Trading Co., Ltd. | Trading Company | Mine Drilling, Block Machines | 100% | 40% | ≤4h | US $50,000+ | 5 models | Semi-auto to full auto |

| Changge Hengruide Machinery Equipment Co., Ltd. | Manufacturer | Construction & Crusher Machinery | 100% | 16% | ≤1h | US $10,000+ | 5 models | Semi-automatic focus |

| SUMU (Shanghai) Automation Engineering Co., Ltd. | Manufacturer | Brick Machinery, Mixers | 100% | 20% | ≤2h | US $10,000+ | 5 high-end models | Full automation, German tech |

| Henan Sinosouth Machinery Co., Ltd. | Manufacturer | Brick/Paver Machines | 100% | 16% | ≤3h | US $120,000+ | 5 models | Hydraulic auto systems |

Performance Analysis

Shandong Kaidong stands out for broad customization depth, offering over a dozen machine variants with options for mold types, control systems, and stacking automation. Despite a modest reorder rate, its 100% on-time delivery and ≤2-hour response reflect strong operational discipline. Zhengzhou Yongsi demonstrates high customer retention (40% reorder rate), indicating effective post-sale support despite being a trading entity—ideal for buyers seeking consolidated sourcing.

SUMU (Shanghai) targets premium segments with Germany-technology-aligned AAC mini-plants priced between $77,000 and $220,000, catering to clients requiring certified lightweight cellular concrete production. Their high price point correlates with advanced automation and compliance readiness. Henan Sinosouth offers mid-tier hydraulic machines with clear pricing transparency and consistent delivery, suitable for emerging market contractors balancing cost and reliability.

FAQs

How to verify AAC block making machine supplier reliability?

Cross-check ISO/CE certifications with official registries. Request factory audit reports or video tours confirming in-house production capabilities. Analyze customer feedback focusing on after-sales service, spare parts availability, and system uptime over 6–12 months.

What is the typical lead time for AAC machine orders?

Standard models require 30–45 days for production and testing. Customized or fully automated lines may take 50–70 days. Shipping via sea freight adds 20–40 days depending on destination port.

Do suppliers offer customization for block size and production capacity?

Yes, most manufacturers allow adjustments in mold dimensions (standard 600×200×100 mm up to 600×300×250 mm), hourly output (4–35 blocks), and raw material compatibility (fly ash, sand, cement ratios). Technical drawings and 3D layouts are typically provided within 5–7 business days.

Can AAC block machines be shipped globally?

All listed suppliers support international shipping. Confirm Incoterms (FOB, CIF, DDP) early in negotiation. Ensure compliance with local electrical standards (voltage: 220V/380V/440V, 50/60Hz) and mechanical safety regulations at destination.

Is sample testing available before bulk purchase?

While full-machine sampling is uncommon due to size and cost, suppliers often provide fabricated AAC blocks produced on identical molds. Alternatively, remote commissioning tests can be scheduled via live video with real-time performance data on vibration frequency, demolding success, and cycle time.