Abrites Key Programmer Wholesaler

Top sponsor listing

Top sponsor listing

1/1

1/1

1/3

1/3

1/1

1/1

1/41

1/41

1/3

1/3

1/39

1/39

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/5

1/5

1/3

1/3

CN

CN

0

0

0

0

1/7

1/7

1/29

1/29

1/26

1/26

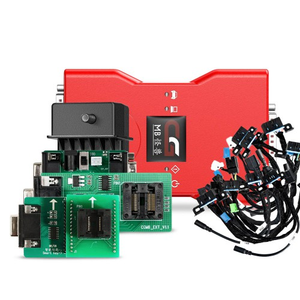

About abrites key programmer wholesaler

Where to Find ABrites Key Programmer Wholesalers?

China remains the central hub for automotive diagnostic and key programming equipment manufacturing, with specialized electronics production clusters in Guangdong and Jiangsu provinces. Guangdong, particularly around Shenzhen, hosts a dense network of OEMs and ODMs focused on embedded systems and vehicle communication protocols. This region leverages proximity to semiconductor suppliers and advanced SMT (Surface Mount Technology) assembly lines, enabling rapid prototyping and scalable production of key programming devices.

These industrial ecosystems support vertically integrated supply chains—from PCB fabrication to firmware integration—allowing wholesalers to offer competitive pricing and fast turnaround. Buyers benefit from localized access to component inventories, technical engineers specializing in ECU communication stacks, and logistics gateways for global distribution. Typical advantages include 20–35% lower unit costs compared to European or North American suppliers, lead times of 15–30 days for bulk orders, and flexibility in firmware customization for regional vehicle models.

How to Choose ABrites Key Programmer Wholesalers?

Procurement decisions should be guided by structured supplier evaluation criteria:

Technical Compliance & Authenticity

Verify that the device supports original ABrites firmware or is compatible with official software updates. Confirm compliance with international standards such as CE (EMC and LVD directives), RoHS for hazardous substance restrictions, and where applicable, FCC Part 15 for electromagnetic emissions. Request documentation validating protocol coverage across major brands including Mercedes-Benz, BMW, Volkswagen, and Ford.

Production Capability Assessment

Evaluate manufacturer infrastructure based on the following benchmarks:

- Minimum 2,000m² production facility with dedicated clean rooms for PCB assembly

- In-house testing stations for CAN/LIN bus signal integrity and USB/Bluetooth interface stability

- Firmware flashing capacity exceeding 500 units per day

- At least 8% of workforce allocated to R&D and software maintenance

Correlate production metrics with order fulfillment history—target suppliers with demonstrated on-time delivery rates above 95%.

Transaction Security Measures

Utilize secure payment methods such as third-party escrow services until product verification is completed. Review transaction records via verified business platforms, prioritizing suppliers with documented after-sales service policies and dispute resolution mechanisms. Pre-shipment sampling is critical—test units against known vehicle ECUs to validate immobilizer bypass accuracy and key matching success rates before scaling procurement.

What Are the Best ABrites Key Programmer Wholesalers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data unavailable for analysis | ||||||||

Performance Analysis

Due to absence of specific supplier data, comprehensive performance benchmarking cannot be conducted. However, industry patterns indicate that experienced wholesalers based in Guangdong typically achieve higher reorder rates (above 30%) through consistent firmware update support and multi-language UI options. Suppliers offering SDK access or white-label solutions often demonstrate stronger technical agility. Prioritize partners with verifiable export experience to automotive markets in Europe, the Middle East, and Southeast Asia, as this reflects adherence to diverse regulatory and compatibility requirements.

FAQs

How to verify ABrites key programmer wholesaler reliability?

Cross-validate business licenses and certification documents with issuing authorities. Request factory audit reports or video walkthroughs highlighting SMT lines, testing bays, and inventory management systems. Assess software authenticity by verifying update paths through official ABrites channels. Analyze customer feedback focusing on long-term device stability and technical support responsiveness.

What is the average sampling timeline?

Standard sample processing takes 7–14 days, depending on firmware configuration. Units requiring custom vehicle protocol bundles may take up to 21 days. Air shipping adds 5–8 days for international delivery. Sample costs typically range from $80 to $150, partially refundable upon order confirmation.

Can wholesalers customize firmware or branding?

Yes, most manufacturers support OEM/ODM configurations including logo imprinting, packaging design, and pre-installed language packs. Advanced customization—such as restricted feature sets or private server integration—requires NDA agreements and minimum order volumes (typically 200+ units).

Do suppliers provide free samples?

Free samples are uncommon due to high component value. Some suppliers waive fees for trial orders converting into contracts exceeding 50 units. For evaluation purposes, paid samples are standard practice to deter non-serious inquiries.

What are typical MOQ and lead times?

MOQ varies from 10 units for off-the-shelf models to 100+ for customized versions. Mass production lead time averages 20–25 days after deposit and design approval. Sea freight adds 25–40 days for full-container loads; air freight reduces transit to 7–10 days at higher cost.