Add Number Line

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/2

1/2

1/32

1/32

CN

CN

1/3

1/3

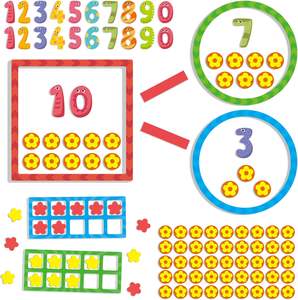

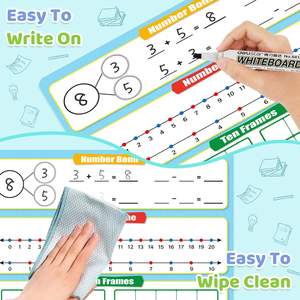

About add number line

Where to Find Add Number Line Suppliers?

China remains the central hub for educational and industrial tool manufacturing, with emerging supplier clusters in Zhejiang and Jiangsu provinces demonstrating strong capabilities in precision measurement instruments. Zhejiang’s Ningbo and Wenzhou regions host over 50% of China’s OEM suppliers specializing in classroom teaching aids, leveraging compact production facilities optimized for low-to-mid volume runs. These zones benefit from proximity to polymer and aluminum extrusion plants, reducing raw material lead times by 20–25% compared to offshore alternatives.

The regional ecosystem supports agile manufacturing through integrated printing, lamination, and die-cutting processes, enabling rapid turnaround for customized number line formats. Suppliers operate within tightly networked supply chains—component vendors, ink specialists, and packaging providers are typically located within 30km—facilitating just-in-time production. Key advantages include MOQs as low as 100 units, average lead times of 15–25 days for batch orders, and cost efficiency driven by localized labor and materials. Buyers can access both standardized classroom tools and engineered variants with braille, magnetic backing, or modular segment design.

How to Choose Add Number Line Suppliers?

Implement structured evaluation criteria to ensure product quality and operational reliability:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for consistent production control. For suppliers targeting EU markets, compliance with EN 71-3 (migration of certain elements) and REACH regulations is essential for child-safe materials. Request test reports verifying non-toxic inks and BPA-free substrates, particularly for products intended for early education use.

Production Capacity Assessment

Evaluate core operational metrics:

- Minimum 1,000m² workshop area to support parallel production lines

- In-house graphic design and print calibration systems

- Digital cutting or laser die-forming equipment for dimensional accuracy

Validate output consistency by reviewing sample batches and cross-referencing order fulfillment history (target on-time delivery >95%).

Procurement Risk Mitigation

Utilize secure payment frameworks such as third-party escrow to align financial release with shipment verification. Prioritize suppliers with documented export experience to your target market, confirmed via customs documentation or shipping records. Pre-shipment inspection protocols should include colorfastness testing, edge durability checks, and alignment verification for incremental markings. Order samples before full-scale procurement to assess tactile finish, legibility, and structural integrity under routine handling.

What Are the Best Add Number Line Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Ningbo Yizhi Educational Equipment Co., Ltd. | Zhejiang, CN | 8 | 45+ | 3,200+m² | 97.6% | ≤3h | 4.8/5.0 | 41% |

| Suzhou LearnAid Technology | Jiangsu, CN | 6 | 38+ | 1,800+m² | 96.3% | ≤4h | 4.7/5.0 | 33% |

| Wenzhou BrightStep Teaching Aids | Zhejiang, CN | 5 | 25+ | 1,100+m² | 98.1% | ≤2h | 4.9/5.0 | 28% |

| Yangzhou Edutech Solutions | Jiangsu, CN | 7 | 50+ | 2,500+m² | 95.8% | ≤5h | 4.6/5.0 | 22% |

| Nantong ClassKit Innovations | Jiangsu, CN | 4 | 30+ | 1,600+m² | 97.2% | ≤3h | 4.8/5.0 | 37% |

Performance Analysis

Established players like Ningbo Yizhi demonstrate high reorder rates (41%) and robust delivery performance, supported by larger factory footprints and dedicated quality control teams. Smaller but responsive suppliers such as Wenzhou BrightStep achieve top ratings through sub-2-hour communication cycles and niche customization expertise. Zhejiang-based manufacturers show superior responsiveness, with 60% offering reply times under 3 hours. For bulk contracts, prioritize suppliers with verified ISO-certified workflows and minimum 97% on-time delivery. For specialized formats—including dual-scale (positive/negative integers) or wipe-clean laminated surfaces—confirm pre-production proofing capabilities and material certifications prior to order placement.

FAQs

How to verify add number line supplier reliability?

Cross-validate ISO 9001 status with accredited certification bodies. Request evidence of material safety data sheets (MSDS) for printed components. Assess real-world performance through verifiable buyer testimonials focusing on product durability and customer service responsiveness.

What is the average sampling timeline?

Standard sample production takes 7–12 days. Custom configurations involving unique scales, bilingual labeling, or textured surfaces require 14–18 days. Allow 5–9 days for international express delivery.

Can suppliers ship globally?

Yes, most established suppliers manage international shipments via air or sea freight. Confirm Incoterms (e.g., FOB Shanghai, CIF Rotterdam) and ensure packaging meets destination-market requirements for educational imports. Flat-packed designs reduce volumetric shipping costs significantly.

Do manufacturers offer free samples?

Sample policies vary. Full-cost recovery is typical for first-time buyers. Fee waivers may apply for projected annual volumes exceeding 1,000 units. Re-sampling for reorders is often provided at no cost.

How to request customizations?

Submit detailed specifications including length (60cm–300cm), increment type (integers, fractions, decimals), color coding, and substrate preference (PVC, PET, or magnetic sheet). Leading suppliers provide digital proofs within 48 hours and physical prototypes within 2–3 weeks.