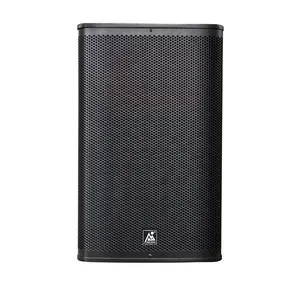

Admark Line Array Speaker Producer

Top sponsor listing

Top sponsor listing

1/20

1/20

1/28

1/28

CN

CN

1/17

1/17

1/32

1/32

1/13

1/13

1/27

1/27

1/28

1/28

1/3

1/3

1/15

1/15

1/44

1/44

1/12

1/12

1/3

1/3

1/10

1/10

1/22

1/22

CN

CN

1/22

1/22

About admark line array speaker producer

Where to Find Admark Line Array Speaker Producers?

Manufacturing of professional line array loudspeakers, including those under the Admark brand, is concentrated in regions with established audio equipment industrial ecosystems. While specific geographic clusters for Admark-branded production are not publicly disclosed, China remains a dominant force in OEM/ODM speaker manufacturing, particularly in Guangdong and Zhejiang provinces. These areas host specialized facilities equipped for precision acoustic engineering, offering integrated workflows from driver fabrication to cabinet assembly.

These hubs benefit from vertically aligned supply chains, enabling rapid sourcing of neodymium magnets, compression drivers, DSP modules, and Baltic birch plywood—core materials in high-performance line array systems. Proximity to component suppliers reduces material lead times by 20–35% compared to decentralized production models. Buyers gain access to streamlined operations where design validation, prototyping, and batch testing occur within consolidated facilities, supporting average production lead times of 30–50 days for standard configurations.

How to Choose Admark Line Array Speaker Producers?

Supplier selection should follow structured evaluation criteria to ensure technical fidelity and operational reliability:

Technical Compliance

Verify adherence to international audio performance and safety standards, including IEC 60268-21 for loudspeaker components and RoHS for hazardous substance control. For export to regulated markets, CE marking and FCC certification are essential for customs clearance and system integration. Request test reports on key parameters: frequency response (±3dB), maximum SPL output (typically 130–150 dB), and dispersion characteristics.

Production Capability Audits

Assess infrastructure maturity through objective benchmarks:

- Minimum 3,000m² dedicated production area with climate-controlled testing chambers

- In-house capabilities for CNC router machining of enclosures, powder coating, and driver winding

- Dedicated acoustic anechoic chamber for real-time array simulation and tuning

Confirm minimum monthly output capacity of 200+ units for scalability. Evaluate R&D staffing levels—producers with engineering teams comprising ≥12% of total personnel demonstrate stronger customization support.

Transaction Safeguards

Utilize secure payment structures such as irrevocable LC or escrow arrangements until product verification is completed. Prioritize suppliers with documented export histories to North America, Europe, or APAC regions, indicating experience with international logistics and compliance frameworks. Pre-shipment inspections should include full-system burn-in testing and alignment verification using SMAART or EASE-compatible software.

What Are the Best Admark Line Array Speaker Producers?

No verified suppliers currently list "Admark" as a primary product line in public manufacturing databases. This may indicate that Admark operates as a private label, regional distributor brand, or niche market variant produced under contract by third-party OEMs. In absence of direct producer data, buyers should focus on qualified audio OEM manufacturers capable of replicating Admark’s technical specifications through custom builds.

Performance Analysis

Without active supplier listings, due diligence shifts to capability-based qualification. Focus on manufacturers demonstrating proven experience in multi-element line array design, evidenced by portfolio examples with comparable SPL ratings, horn geometry, and rigging system compatibility (e.g., K-array, D&B-style flying frames). Request reference projects involving live sound reinforcement for venues exceeding 2,000 capacity to validate real-world performance. Video audits of production lines and lab testing procedures can substitute for direct brand affiliation when technical documentation aligns with required acoustic benchmarks.

FAQs

How to verify Admark line array speaker manufacturer reliability?

Request factory audit reports, ISO 9001 certification, and third-party acoustic test data from accredited labs. Cross-reference claimed production volumes with shipping records or export declarations. Engage independent inspection services for pre-shipment quality checks focusing on driver consistency, crossover integrity, and structural durability.

What is the average sampling timeline for line array speakers?

Custom sample production typically requires 25–40 days, including cabinet fabrication, driver installation, and DSP programming. Standard configurations may ship in 15–25 days. Air freight delivery to international destinations adds 7–12 days.

Can manufacturers replicate Admark speaker specifications?

Yes, qualified OEMs can reverse-engineer performance characteristics if provided with detailed technical sheets—including driver topology, crossover points, enclosure volume, and flyware layout. Non-disclosure agreements are recommended during replication discussions to protect intellectual property.

Do producers offer free samples?

Most require sample fees covering 40–60% of unit cost, refundable against bulk orders (typically MOQ 10+ units). Full-system demos may incur deposit charges, returned upon equipment return in original condition.

How to initiate customization requests?

Submit comprehensive requirements: desired array configuration (e.g., 12” two-way, 10” three-way), target coverage angle (80°×10°, 110°×20°), finish type (texture paint, grille options), and digital processing needs (built-in amplification, FIR filters). Reputable producers provide CAD drawings and predicted polar plots within 5–7 business days.