Advanced Mfg

Top sponsor listing

Top sponsor listing

CN

CN

About advanced mfg

Where to Find Advanced Manufacturing Service Suppliers?

China remains the global epicenter for advanced manufacturing services, with key industrial hubs in Jiangsu, Fujian, and Guangdong provinces driving innovation and scalability. Suzhou and Dongguan have emerged as centers for high-precision machining and custom fabrication, hosting vertically integrated facilities that combine CNC processing, sheet metal work, and rapid prototyping under one roof. These clusters benefit from proximity to Tier-1 automotive, aerospace, and electronics OEMs, enabling just-in-time delivery and agile response to engineering changes.

The region’s mature supply ecosystems support end-to-end production, from raw material sourcing to final assembly and packaging. Suppliers leverage localized networks of tooling shops, heat treatment providers, and metrology labs within 50km radii, reducing lead times by 20–30% compared to offshore alternatives. Average turnaround for custom machined parts ranges from 15–25 days, with express prototyping available in 7–10 days. Cost efficiencies stem from automated workflows and economies of scale, offering 25–40% lower unit pricing than equivalent Western manufacturers for medium-to-high volume runs.

How to Choose Advanced Manufacturing Service Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

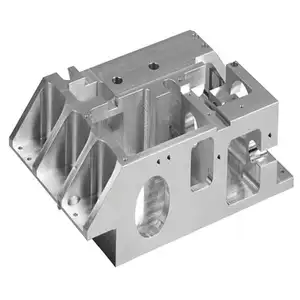

Technical Capabilities & Compliance

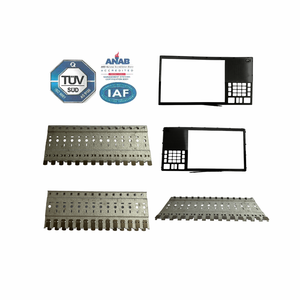

Verify ISO 9001 certification as a baseline for quality management systems. For regulated industries (aerospace, medical), confirm adherence to AS9100 or ISO 13485 standards. Assess equipment inventory: suppliers should operate multi-axis CNC machines (3-, 4-, and 5-axis), precision milling, turning, and grinding centers. In-house design and simulation software (e.g., CAD/CAM, GD&T analysis) indicates stronger engineering support for complex geometries and tight tolerances (±0.005mm).

Production Infrastructure Audit

Evaluate core capacity indicators:

- Facility size exceeding 2,000m² for scalable production

- Dedicated R&D or engineering team handling DFM feedback

- In-house capabilities covering machining, casting, molding, and surface finishing

Cross-reference response time data (target ≤4 hours) and on-time delivery rates (ideal ≥95%) as proxies for operational efficiency and order prioritization.

Customization & Quality Assurance

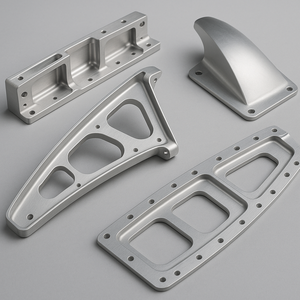

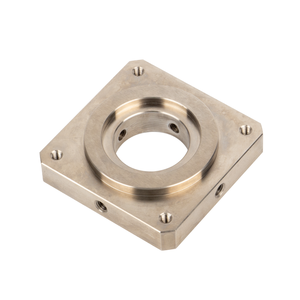

Confirm availability of full customization options including material selection (aluminum, stainless steel, titanium, engineering plastics), surface treatments (anodizing, plating, powder coating), and branding (laser engraving, labeling). Demand access to first-article inspection reports (FAIR), CMM reports, and process capability studies (Cp/Cpk) for critical features. Prioritize suppliers offering free prototyping or low-cost sampling for design validation.

What Are the Best Advanced Manufacturing Service Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Suzhou Konlida Precision Electronic Co., Ltd. | Machining Services (387), Insulation Materials (241), RF/EMI Shielding (139) | 100% | ≤3h | 21% | US $440,000+ | Color, material, size, precision drawing, logo, packaging, label, graphic |

| TTQ INDUSTRIAL EQUIPMENT MANUFACTURE COMPANY LIMITED | Cashew Processing Machines (513), Vacuum Packers (67), Testing Equipment (58) | - | ≤8h | - | - | Not specified |

| SkyReach Intelligent MFG Limited | Precision Machining Parts, Aluminum Fabrication, CNC Components | 84% | ≤4h | 16% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

| Dongguan Shipai Jingqi Hardware Products Factory | Machining Services (1030), Sheet Metal Fabrication (150), Pinion Gears (25) | 100% | ≤1h | <15% | US $10,000+ | Not specified |

| Xiamen Yingtusheng Precision Technology Co., Ltd. | Machining Services (128), Moulds (88), Sheet Metal (55) | 100% | ≤3h | 100% | US $3,000+ | Material, size, logo, packaging, label, graphic |

Performance Analysis

Suzhou Konlida and Dongguan Shipai Jingqi stand out for reliability, both achieving 100% on-time delivery with sub-3-hour response times. Konlida’s extensive product range and high reorder rate (21%) reflect strong customer retention in precision electronics and insulation components. Xiamen Yingtusheng demonstrates exceptional loyalty with a 100% reorder rate, indicating consistent quality in aerospace and aviation part manufacturing despite lower online revenue. Dongguan Shipai leads in responsiveness (≤1h), ideal for urgent RFQs, while SkyReach offers broad customization but lags in delivery performance (84%). TTQ focuses on niche food processing machinery, suggesting specialized expertise outside mainstream industrial fabrication.

FAQs

How to verify advanced manufacturing supplier credibility?

Request documented proof of certifications (ISO 9001, CE, RoHS) and conduct virtual factory audits to assess machinery condition and workflow organization. Analyze transaction history for consistency in order fulfillment and review customer testimonials focusing on dimensional accuracy and post-delivery support.

What is the typical MOQ and pricing structure?

Minimum order quantities typically start at 1 piece for prototypes and low-volume runs. Unit prices range from $0.38–$3.89 for standard machined components, scaling down with volume. High-complexity parts (e.g., 5-axis aerospace brackets) may require MOQs of 100–1,000 units.

Do suppliers support full design-to-production workflows?

Yes, leading providers offer OEM/ODM services with engineering collaboration. Submit 3D models (STEP, IGES) or 2D drawings with tolerances and material specs. Most suppliers return DFM feedback within 24–48 hours and provide digital renderings for approval prior to production.

What are common lead times for samples and mass production?

Sample lead time averages 7–14 days for simple CNC parts, extending to 21 days for complex assemblies requiring secondary operations. Mass production timelines range from 20–35 days depending on order size and finishing requirements. Express services can reduce timelines by 30–50% at a premium.

Are shipping and export documentation handled by suppliers?

Most suppliers manage export packaging and provide essential documentation (commercial invoice, packing list, bill of lading). Buyers are responsible for import clearance unless CIF terms are negotiated. Air freight takes 5–7 days globally; sea freight requires 25–40 days depending on destination port.