Advanced Precision Machining Inc

Top sponsor listing

Top sponsor listing

1/8

1/8

CN

CN

1/34

1/34

About advanced precision machining inc

Where to Find Advanced Precision Machining Suppliers?

China remains a global hub for advanced precision machining services, with key manufacturing clusters concentrated in Guangdong and Shanghai. Dongguan and Shenzhen in Guangdong province host vertically integrated facilities specializing in CNC turning, milling, and multi-axis machining, supported by mature ecosystems of material suppliers, tooling specialists, and logistics providers within 50km radii. These regions offer lead times averaging 15–25 days for custom machined components, with localized supply chains reducing production costs by 20–30% compared to Western counterparts.

Shanghai’s precision machinery sector benefits from proximity to R&D centers and high-end industrial zones, enabling tight-tolerance processing (±0.005mm) for aerospace, medical, and automation applications. The region’s focus on automation integration and smart manufacturing has increased output efficiency by 18% over the past three years. Buyers gain access to scalable production networks capable of fulfilling both low-volume prototypes and high-volume runs, with many suppliers offering rapid turnaround for orders under 1,000 units.

How to Choose Advanced Precision Machining Suppliers?

Evaluate potential partners using the following criteria to ensure technical compliance and operational reliability:

Technical Capabilities & Certifications

Confirm adherence to ISO 9001 standards as a baseline for quality management. For regulated industries such as medical or aerospace, verify additional certifications including ISO 13485 or AS9100. Assess capability for secondary operations—such as anodizing, plating, stamping, or assembly—which indicate process integration and reduced outsourcing risks.

Production Infrastructure Assessment

Key indicators of scalable capacity include:

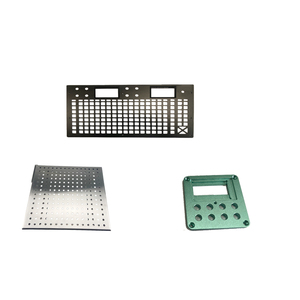

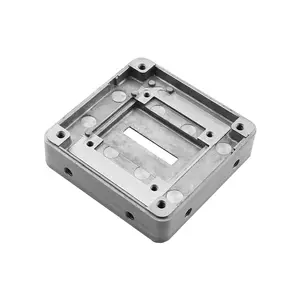

- In-house CNC machining centers with 3-, 4-, and 5-axis capabilities

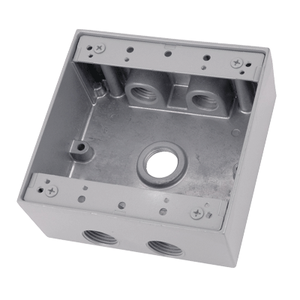

- Sheet metal fabrication and die casting lines for integrated part production

- Dedicated quality control stations equipped with CMMs, optical comparators, and surface roughness testers

Cross-reference supplier claims with verified performance metrics: prioritize those with on-time delivery rates exceeding 90% and response times under 4 hours.

Customization & Transaction Safeguards

Ensure suppliers support full customization across materials (aluminum, stainless steel, PEEK, brass), finishes (brushing, coating, laser engraving), and packaging. Require detailed drawings and prototype validation before mass production. Utilize secure transaction methods with milestone-based payments, especially for first-time engagements. Request sample parts to verify dimensional accuracy and surface finish against provided specifications.

What Are the Best Advanced Precision Machining Suppliers?

| Company Name | Location | Main Services | Materials Handled | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Guangdong, CN | Sheet Metal Fabrication, Machining, Casting | Steel, Aluminum, Metal Tubes, Rubber Coating | 97% | ≤3h | 46% | US $1,700,000+ | Color, size, logo, label, design, packaging |

| Shanghai Huazhicheng Precision Machinery Co., Ltd. | Shanghai, CN | Machining Services, Sheet Metal Fabrication | Aluminum, Steel | 100% | ≤3h | <15% | US $3,000+ | Limited data available |

| Dongguan Sinbo Precision Mechanical Co., Ltd. | Guangdong, CN | CNC Machining, Rapid Prototyping, Casting | Aluminum, Stainless Steel | 92% | ≤10h | 60% | US $1,200,000+ | Material, finish, size, accessories |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Advanced Engineering, 5-Axis CNC Machining | Aluminum, General Metals | 84% | ≤4h | 16% | US $20,000+ | Color, material, logo, graphic, packaging |

| Dongguan Chuanglixin Precision Hardware Co., Ltd. | Guangdong, CN | CNC Turning, PEEK Machining, Sheet Metal | PEEK, Steel, Aluminum | 85% | ≤1h | <15% | US $6,000+ | Size, material, finish, OEM/ODM support |

Performance Analysis

Shenzhen Runze and Dongguan Sinbo demonstrate strong customer retention, with reorder rates of 46% and 60% respectively, indicating consistent quality and service satisfaction. Shanghai Huazhicheng stands out with a perfect 100% on-time delivery record, though its lower online revenue and reorder rate suggest limited order volume or newer market presence. SkyReach and Chuanglixin offer fast response times (≤4h and ≤1h), beneficial for urgent RFQs, but their sub-85% delivery performance may pose fulfillment risks for time-sensitive projects. Suppliers with higher revenue (>US $1 million) typically operate larger facilities with diversified equipment, better supporting complex, multi-process jobs.

FAQs

How to verify advanced precision machining supplier reliability?

Request documented proof of ISO certification and conduct virtual factory audits to assess machinery conditions and workflow organization. Analyze transaction history for consistency in delivery and communication. Prioritize suppliers with third-party verification badges and verifiable client references in your industry segment.

What is the typical MOQ and pricing structure?

Minimum order quantities range from 1 piece (prototypes) to 50–100 pieces for cost-effective production runs. Unit prices vary by complexity and material: aluminum components start at $0.10/unit, while specialized materials like PEEK can reach $4.50/unit. High-volume orders (>10,000 units) typically unlock negotiated pricing and dedicated production scheduling.

Do suppliers support rapid prototyping?

Yes, most suppliers listed offer rapid prototyping with lead times of 5–10 days. Technologies include 3-axis and 5-axis CNC machining, EDM, and turn-mill combo processes. Digital quoting systems enable same-day feedback, with 3D models and inspection reports provided upon completion.

Can I request customized finishes and branding?

Full customization is widely available, including anodizing, powder coating, laser etching, and custom packaging with branded labels. Suppliers support OEM/ODM workflows, allowing integration of client-specific designs, logos, and serial numbering. Confirm compatibility with required environmental or wear-resistant standards (e.g., MIL-A-8625 for anodizing).

What are standard lead times and shipping options?

Production lead times average 15–25 days post-approval of samples. Air freight adds 5–7 days for international delivery, suitable for small batches. Sea freight is recommended for bulk shipments, taking 25–35 days but reducing per-unit logistics costs by up to 60%.