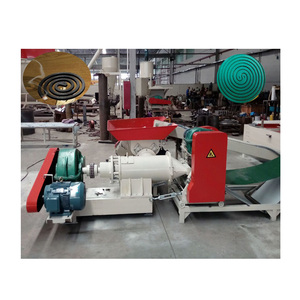

Agarbatti Making Machine Automatic

About agarbatti making machine automatic

Where to Find Agarbatti Making Machine Automatic Suppliers?

China remains the central hub for automated incense (agarbatti) making machinery production, with key manufacturing clusters in Henan and Zhecheng regions. These zones host vertically integrated facilities specializing in food-grade extrusion systems, precision molding, and multi-functional packaging integration. Henan province accounts for over 70% of China’s industrial-scale agarbatti machine output, supported by mature supply chains for stainless steel components, electric motors, and PLC control systems.

The concentration of engineering talent and component suppliers within 50km radii enables rapid prototyping and assembly. This ecosystem supports scalable production runs—from single-unit exports to bulk orders exceeding 50 sets monthly. Buyers benefit from localized sourcing of critical materials such as SUS304 stainless steel dies, Teflon-coated molds, and frequency-controlled drive systems, reducing lead times to 25–40 days for standard configurations. Cost efficiency is further enhanced by 15–25% lower labor and logistics expenses compared to Southeast Asian or Indian alternatives.

How to Choose Agarbatti Making Machine Automatic Suppliers?

Procurement decisions should be guided by systematic evaluation criteria focused on technical capability, operational reliability, and transactional transparency.

Technical Compliance

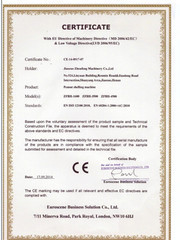

Verify adherence to international electrical and mechanical safety standards. While ISO 9001 certification is not universally present among listed suppliers, it should be a baseline requirement for high-volume buyers. For EU and North American markets, CE marking confirms compliance with electromagnetic compatibility (EMC) and low-voltage directives. Confirm motor specifications (typically 220V/50Hz or 380V/3-phase) align with local power infrastructure.

Production Capability Audits

Assess supplier infrastructure using verifiable metrics:

- Minimum factory area of 3,000m² indicating capacity for full production lines

- In-house R&D teams capable of customizing die plates, conveyor speeds, and feed mechanisms

- On-site CNC machining and welding capabilities for rapid maintenance and modification

Cross-reference online revenue data and on-time delivery rates—suppliers reporting >$400,000 annual digital sales demonstrate proven export scalability.

Transaction Safeguards

Utilize secure payment frameworks such as escrow services until post-delivery performance verification. Prioritize suppliers with documented quality control procedures, including pre-shipment testing of extrusion consistency and motor load endurance. Request video demonstrations of live machine operation before finalizing orders. Sampling remains critical—benchmark stick uniformity, skewer alignment accuracy, and hourly output rates against claimed specifications.

What Are the Best Agarbatti Making Machine Automatic Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) | Product Count |

|---|---|---|---|---|---|---|---|---|

| Zhecheng Hong Xin Machinery Factory | Zhecheng, CN | US $620,000+ | 100% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | $1,000–$5,000 | 5 |

| Zhengzhou Share Machinery Co., Ltd. | Henan, CN | US $420,000+ | 100% | ≤3h | <15% | Not specified | $2,499–$3,199 | 5 |

| Henan Olilang Machinery Co., Ltd. | Henan, CN | US $40,000+ | 85% | ≤2h | <15% | Not specified | $550–$2,500 | 5 |

| Zhengzhou Joycan Machinery Co., Ltd. | Henan, CN | US $140,000+ | 100% | ≤7h | 25% | Customized models available | $550–$1,000 | 5 |

| Lerford Machine LLC | Not specified | Not available | Not available | ≤2h | Not available | Not specified | $1,000–$3,980 | 3 |

Performance Analysis

Zhecheng Hong Xin Machinery Factory leads in operational scale and customization depth, backed by verified multispecialty status and 100% on-time delivery. Zhengzhou Share Machinery matches this reliability with strong technical offerings in fully automatic Tibetan and dhoop cone machines. Henan Olilang stands out for affordability, offering entry-level units from $550, though its 85% on-time delivery rate indicates potential fulfillment risks. Zhengzhou Joycan demonstrates higher customer retention (25% reorder rate), suggesting competitive after-sales support despite slower response cycles. Buyers seeking budget options may consider Joycan or Olilang, while those prioritizing precision and scalability should engage Hong Xin or Share Machinery for engineered solutions.

FAQs

How to verify agarbatti making machine supplier reliability?

Cross-check declared certifications (ISO, CE) through issuing bodies. Analyze transaction history via platform-verified revenue reports and delivery performance. Request references from past international clients and review feedback on service responsiveness and machine durability under continuous operation.

What is the average sampling timeline?

Standard sample production takes 10–20 days depending on complexity. Machines with specialized dies or voltage adaptations require 25–35 days. Air freight adds 5–10 days for global delivery. Expect partial sample cost recovery upon subsequent order placement.

Can suppliers ship agarbatti making machines worldwide?

Yes, established manufacturers offer FOB, CIF, and DAP shipping terms. Confirm inclusion of export documentation, crating specifications, and customs code classification (HS 8479.89). Sea freight is optimal for container loads; air express suits urgent single-unit deliveries.

Do manufacturers provide free samples?

Free samples are rare due to equipment size and production cost. Most suppliers charge 30–50% of unit price for sampling, redeemable against future bulk orders. Exceptions may apply for purchases exceeding five units.

How to initiate customization requests?

Submit detailed requirements including desired output capacity (sticks/hour), raw material type (bamboo-less, wood powder, masala), voltage, and physical dimensions. Reputable suppliers will respond with CAD layouts, process flow diagrams, and estimated cycle times within 72 hours.