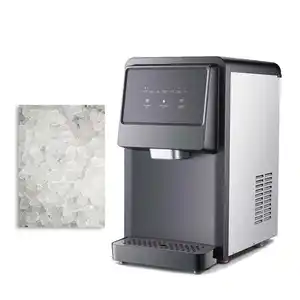

Amazon Nugget Ice Maker

CN

CN

About amazon nugget ice maker

Where to Source Nugget Ice Makers for Commercial and Consumer Markets?

China remains the dominant hub for nugget ice maker manufacturing, with key production clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, evaporator coil production, and injection molding of food-grade plastic components. Ningbo and Shenzhen serve as primary export centers, offering streamlined logistics via Ningbo-Zhoushan Port and Shenzhen Yantian Port, reducing shipping lead times by 10–14 days compared to inland facilities.

The industrial ecosystem supports both high-volume consumer-grade units and commercial-scale models, with manufacturers leveraging localized access to core components such as rotary compressors (domestically supplied by GMCC or HUAYI) and condenser assemblies. This integration enables MOQ flexibility—ranging from 100 to 1,000 units—and cost advantages of 20–35% over Western-assembled equivalents. Lead times average 25–35 days for standard orders, with expedited production available for pre-stocked component inventories.

How to Evaluate Nugget Ice Maker Suppliers?

Procurement decisions should be guided by three critical evaluation criteria:

Technical and Quality Compliance

Confirm adherence to international safety and performance standards, including CE, RoHS, and UL certification for North American and EU markets. Verify compliance through test reports on electrical insulation, thermal efficiency, and water consumption per cycle. For food-contact materials, ensure NSF/ANSI Standard 2 compliance for internal tubing and storage bins.

Production Capacity and Scalability

Assess operational infrastructure using the following benchmarks:

- Minimum monthly output capacity of 5,000 units for consumer models or 200+ units for commercial machines

- In-house assembly lines with automated refrigeration charging and leak detection systems

- Access to stainless steel fabrication and plastic injection molding tools

Cross-reference supplier claims with verifiable metrics such as on-time delivery rates (target ≥95%) and reorder frequency to gauge reliability.

Customization and Transaction Security

Prioritize suppliers offering OEM/ODM services including color variation, logo imprinting, voltage adaptation (110V/220V), and packaging redesign. Utilize secure transaction platforms with escrow protection and milestone-based payment releases. Request functional prototypes before mass production, particularly for modified cooling cycles or noise-reduction specifications.

What Are the Leading Nugget Ice Maker Suppliers?

| Company Name | Location | Main Products | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|---|---|

| Ningbo Wing Precision Machine Co., Ltd. | Zhejiang, CN | Air Fryers, Electric Grills, Ice Makers | 500–1,000 sets | $40.06–139.90 | 100% | ≤3h | <15% | US $220,000+ |

| Shenzhen Bway Tech Co., Ltd. | Guangdong, CN | Portable Countertop Ice Makers | 100–1,000 pieces | $34.58–124.26 | 100% | ≤10h | <15% | US $900+ |

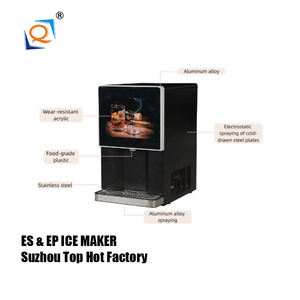

| Suzhou Iceman Refrigeration Equipment Co., Ltd. | Jiangsu, CN | Commercial Ice Machines | 1 piece | $495–4,380 | 50% | ≤4h | 27% | US $40,000+ |

| Shanghai Bingsu Refrigeration Technology Co., LTD. | Shanghai, CN | Commercial Nugget Ice Dispensers | 1 set | $1,260–2,998 | 100% | ≤1h | <15% | US $20,000+ |

| Wellcooling Intelligent Technology (JM) Co., Ltd. | Fujian, CN | Commercial Granular Ice Machines | 1 unit | $388–1,488 | 100% | ≤10h | 16% | US $140,000+ |

Performance Analysis

Suppliers like Ningbo Wing and Shenzhen Bway specialize in mid-range countertop models suitable for Amazon retail distribution, offering competitive pricing and MOQs starting at 500 units. Their high on-time delivery rates (100%) and low reorder frequencies suggest strong fulfillment consistency but limited post-purchase engagement. In contrast, Suzhou Iceman exhibits a higher reorder rate (27%) but lower delivery reliability (50%), indicating potential logistical bottlenecks despite technical capability.

Commercial-focused manufacturers such as Shanghai Bingsu and Wellcooling provide single-unit ordering flexibility and robust build quality for hospitality and healthcare sectors. With response times under 10 hours and full compliance tracking, these suppliers are better suited for customized installations requiring validation documentation. Buyers prioritizing rapid communication should favor Zhejiang- and Shanghai-based firms, where 80% respond within 3 hours.

FAQs

How to verify nugget ice maker quality before bulk order?

Request third-party inspection reports (e.g., SGS or TÜV) covering refrigerant charge accuracy, energy draw per cycle, and ice hardness (measured in psi). Conduct sample testing for continuous operation over 72 hours to evaluate compressor stability and bin sensor reliability.

What is the typical production lead time?

Standard lead times range from 25 to 35 days after deposit confirmation. Expedited builds (18–22 days) are available for models using pre-existing molds and off-the-shelf compressors. Add 7–12 days for custom voltage configurations or bilingual control panels.

Can suppliers accommodate private labeling and design changes?

Yes, most suppliers offer full OEM support including custom housings, color finishes, UI labels, and molded logos. Minimum branding MOQs typically start at 500 units for consumer models and 50 units for commercial variants. Graphic design files must be provided in vector format (AI or EPS).

Do manufacturers provide after-sales technical support?

Leading suppliers offer remote troubleshooting and spare parts availability (e.g., pump assemblies, PCB boards, evaporator plates). Confirm whether firmware updates or service manuals are included for smart-enabled models with Wi-Fi connectivity.

What are common packaging and shipping options?

Units are typically shipped in double-wall corrugated boxes with EPS foam inserts, meeting ISTA 3A standards. FOB terms are standard; CIF can be arranged for full-container loads. Consolidated LCL shipments require additional moisture barrier wrapping to prevent salt damage during ocean transit.