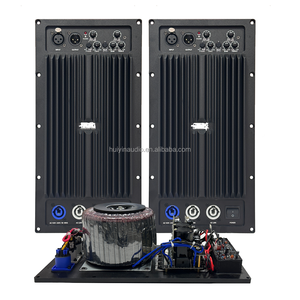

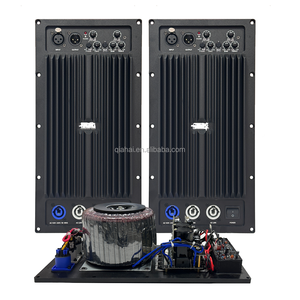

Amplifier Module For Active Subwoofer Distributor

1/3

1/3

1/3

1/3

0

0

1/32

1/32

1/3

1/3

1/3

1/3

1/19

1/19

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

1/1

1/1

1/3

1/3

1/2

1/2

About amplifier module for active subwoofer distributor

Where to Find Amplifier Module for Active Subwoofer Suppliers?

China remains the central hub for amplifier module manufacturing, with key production clusters in Guangdong and Jiangsu provinces. Guangdong, particularly the Pearl River Delta region including Shenzhen and Dongguan, hosts over 70% of China’s audio electronics suppliers, supported by dense networks of PCB fabricators, semiconductor distributors, and SMT assembly lines. This concentration enables rapid prototyping and high-volume production, with integrated supply chains reducing component procurement lead times by up to 40% compared to non-specialized regions.

Jiangsu’s Changzhou and Suzhou zones focus on precision electronics manufacturing, offering advanced surface-mount technology (SMT) and automated testing systems. These industrial ecosystems support efficient scale-up from pilot runs to monthly outputs exceeding 50,000 units per facility. Proximity to Shanghai port facilitates global distribution, while localized sourcing of core materials—such as aluminum heat sinks, FR-4 PCB substrates, and Class-D ICs—contributes to 15–25% lower production costs than equivalent Western or Southeast Asian operations.

How to Choose Amplifier Module for Active Subwoofer Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality Management Compliance

Require ISO 9001 certification as a baseline for process control. For export to regulated markets (EU, North America), confirm RoHS and CE compliance for electromagnetic compatibility (EMC) and restricted substances. Review test reports for THD (Total Harmonic Distortion), signal-to-noise ratio, and thermal stability under continuous load conditions.

Production Infrastructure Assessment

Evaluate supplier capabilities based on physical and technical assets:

- Minimum 2,000m² factory area with ESD-protected SMT and assembly zones

- In-house PCB printing, reflow soldering, and aging test facilities

- Dedicated R&D team capable of firmware tuning and protection circuit design

Validate production capacity through order history and cross-reference delivery performance (target >97% on-time rate) with facility scalability.

Procurement Risk Mitigation

Utilize secure transaction models such as third-party inspection services prior to shipment. Request sample units to verify build quality, heatsink efficiency, and driver integration with passive components. Confirm that suppliers conduct 100% functional testing and provide traceable batch documentation for critical ICs and power transistors.

What Are the Best Amplifier Module for Active Subwoofer Suppliers?

No verified suppliers are currently available in the dataset. Buyers should prioritize partners with documented experience in Class-D amplifier design, proven export compliance, and transparent manufacturing workflows. Given the absence of listed entities, due diligence becomes critical—focus on companies demonstrating clear technical specifications, responsive communication, and adherence to international quality standards.

Performance Analysis

In mature electronics sourcing markets like Guangdong, responsiveness and technical agility often correlate with long-term reliability. Leading suppliers typically maintain response times under 4 hours, offer MOQs ranging from 100 to 500 units, and support customization including variable output power (100W–1000W), short-circuit protection logic, and custom PCB form factors. Prioritize manufacturers with video audit availability, real-time production tracking, and documented after-sales service records. Absent concrete data, buyers should initiate engagement with shortlisted candidates through sample validation and incremental order scaling.

FAQs

How to verify amplifier module supplier reliability?

Validate certifications through official databases and request independent lab test results for EMC and thermal performance. Conduct virtual or on-site audits to assess SMT line automation, component traceability, and QC protocols. Analyze customer feedback focused on field failure rates and technical support responsiveness.

What is the average sampling timeline?

Standard amplifier module samples take 7–14 days for production. Custom designs requiring new PCB layouts or firmware adjustments may require 20–30 days. Air freight adds 5–8 days for international delivery.

What are typical MOQ and lead times?

MOQs range from 100 to 500 units for standard configurations. Mass production lead times average 25–35 days post-approval, depending on component availability and order volume. JIT delivery options exist for repeat buyers with forecast sharing agreements.

Can suppliers customize amplifier modules?

Yes, most manufacturers support tailored output power, input sensitivity, crossover settings, and protection features. Provide detailed schematics or performance requirements to enable accurate quoting. Expect NRE fees for significant redesigns involving new PCB masks or MCU programming.

Do suppliers provide technical documentation?

Reputable suppliers deliver comprehensive datasheets, pinout diagrams, layout recommendations, and compliance certificates. Confirm inclusion of English-language manuals and BOMs for seamless integration into downstream assembly processes.