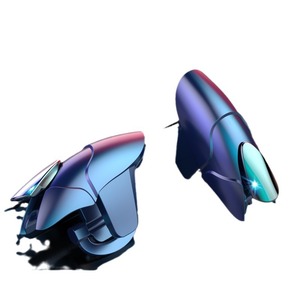

Android Game Support Controller

Top sponsor listing

Top sponsor listing

0

0

1/16

1/16

1/3

1/3

1/22

1/22

0

0

1/3

1/3

1/3

1/3

0

0

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

0

0

About android game support controller

Where to Find Android Game Support Controller Suppliers?

China remains the central hub for consumer electronics manufacturing, with key production clusters in Guangdong and Jiangsu provinces driving innovation and scale in gaming peripherals. Guangdong, particularly the Shenzhen-Dongguan corridor, hosts over 70% of China’s electronic game accessory suppliers, leveraging its dense ecosystem of PCB fabricators, wireless module producers, and smart device OEMs. This integration enables rapid prototyping and cost-efficient mass production, with localized supply chains reducing component procurement lead times by up to 40% compared to non-specialized regions.

These industrial zones support vertically integrated operations—from SMT assembly lines to final product testing—allowing for agile fulfillment of both standard and customized controller orders. Buyers benefit from proximity to Tier-1 component suppliers, firmware development teams, and logistics networks capable of handling air and sea freight for global distribution. Typical advantages include MOQs as low as 500 units, average production lead times of 25–35 days, and per-unit cost reductions of 18–25% due to economies of scale and streamlined material flow within 30km supplier radii.

How to Choose Android Game Support Controller Suppliers?

Adopt structured evaluation criteria to mitigate sourcing risks:

Quality & Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management, RoHS for hazardous substance compliance, and CE/FCC for electromagnetic compatibility. For Android-specific functionality, validate Bluetooth 5.0+ certification and HID protocol compatibility through technical documentation. Request test reports on battery safety (if applicable), button cycle durability (minimum 1 million presses), and latency performance under real-world conditions.

Production Capacity Assessment

Evaluate operational infrastructure using objective benchmarks:

- Minimum 3,000m² factory area with dedicated clean-room SMT lines

- In-house R&D team comprising at least 15% of total staff for firmware and ergonomic design

- Automated optical inspection (AOI) systems and ESD-safe assembly stations

Correlate facility size with monthly output capacity (target: 100,000+ units) and verify consistency via historical shipment data and on-time delivery records (benchmark: ≥95%).

Procurement Risk Mitigation

Utilize secure transaction models such as third-party escrow or letter of credit for initial large-volume orders. Review supplier export experience—prioritize those with documented shipments to North America, EU, or Japan, indicating familiarity with regional regulatory requirements. Conduct sample validation to assess build quality, joystick precision, vibration feedback, and pairing stability across multiple Android OS versions before full-scale production.

What Are the Best Android Game Support Controller Suppliers?

No supplier data is currently available for this product category. Procurement professionals are advised to initiate targeted sourcing inquiries through verified B2B channels, focusing on manufacturers with demonstrated experience in Bluetooth-enabled human interface devices (HID). When evaluating potential partners, request facility videos, product tear-down analyses, and customer references from prior gaming peripheral contracts to establish credibility.

Performance Analysis

In absence of published supplier metrics, emphasis should be placed on validating technical capability through direct engagement. Prioritize manufacturers advertising certified production lines, active R&D pipelines, and compliance with mobile gaming hardware specifications. Given the competitive nature of the market, responsiveness (target: ≤4-hour reply time), flexibility in MOQ adjustments, and willingness to provide pre-production samples are strong indicators of reliable partnership potential.

FAQs

How to verify android game controller supplier reliability?

Cross-validate certifications with accredited bodies and request audit trails covering incoming component inspection, in-process quality checks, and final product testing. Analyze customer feedback focusing on defect rates, packaging integrity, and post-delivery technical support responsiveness.

What is the average sampling timeline?

Standard sample production typically takes 10–18 days, including programming for Android HID profile recognition. Custom designs with unique casing molds or button layouts may require 25–35 days. Add 5–9 days for international express shipping depending on destination.

Can suppliers ship controllers worldwide?

Yes, experienced manufacturers manage global logistics via air freight, LCL, or FCL sea containers. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam), ensure proper classification under HS code 8543.70 for customs clearance, and verify compliance with local telecom and safety regulations (e.g., FCC Part 15 in the U.S.).

Do manufacturers provide free samples?

Sample policies vary: some suppliers offer complimentary units for qualified buyers committing to minimum order volumes (typically 1,000+ units). Otherwise, expect to cover sample costs plus shipping, which may be partially or fully reimbursed upon order confirmation.

How to initiate customization requests?

Submit detailed technical requirements including外形 dimensions, button layout, connectivity type (Bluetooth/BT 5.0+/2.4G), battery capacity, material specifications (ABS/PC blend), and firmware features (e.g., programmable buttons, RGB lighting). Reputable suppliers will respond with CAD drawings, circuit schematics, and prototype timelines within 5–7 business days.