Api Production

CN

CN

CN

CN

About api production

Where to Find API Production Line Suppliers?

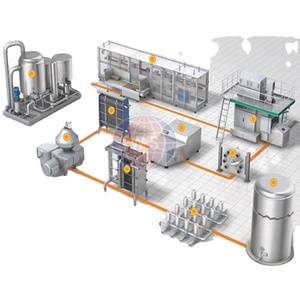

China remains the central hub for industrial automation and food processing line manufacturing, with key supplier clusters in Guangdong, Jiangsu, and Shanghai. These regions host vertically integrated facilities specializing in turnkey production systems for high-volume consumer goods such as dairy, confectionery, and packaged foods. Guangdong’s Foshan-Dongguan corridor supports rapid prototyping and export logistics, while Jiangsu’s machinery corridor near Nanjing offers cost-efficient access to steel and electrical components. Shanghai’s proximity to R&D institutions enables integration of smart controls and IoT monitoring into production lines.

Suppliers in these zones operate under mature ecosystems where engineering, fabrication, and testing are conducted in-house, reducing dependency on external vendors. This vertical integration allows lead times averaging 45–60 days for fully automated systems. Buyers benefit from localized supply chains that reduce equipment costs by 20–35% compared to European or North American manufacturers, particularly for customized configurations requiring specialized tooling or material handling integration.

How to Choose API Production Line Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international quality standards such as ISO 9001 for quality management. For food-grade applications, ensure compliance with hygiene regulations including 3A, EHEDG, or FDA standards where applicable. Request documentation for material certifications (e.g., SS304/SS316 stainless steel) and validation reports for critical processes like sterilization, homogenization, or filling accuracy.

Production Capability Verification

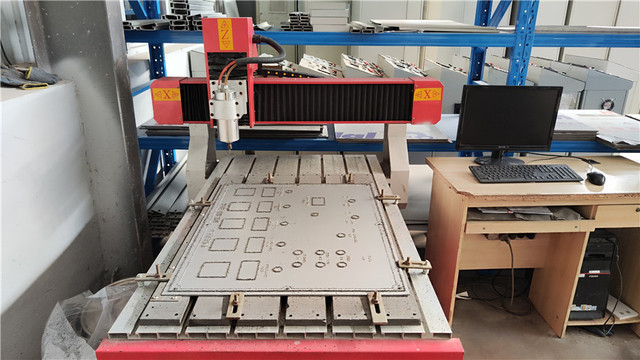

Assess core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to support full-line assembly

- In-house engineering teams capable of system design, PLC programming, and HMI interface development

- On-site CNC machining, welding, and control panel fabrication capabilities

Cross-reference declared production capacity with verified delivery performance. Prioritize suppliers maintaining on-time delivery rates above 90%, supported by real-time project tracking systems.

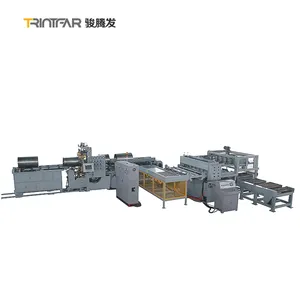

Customization & Integration Expertise

Evaluate scope of customization: color coding, material specifications, logo imprinting, packaging synchronization, and automation level adjustments. Confirm ability to modify line speed, product weight tolerance, and format changeovers. Suppliers offering digital twin simulations or 3D layout modeling provide higher confidence in system compatibility.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services tied to milestone verification. Require post-installation support including commissioning assistance, operator training, and remote diagnostics. Review historical reorder rates as an indicator of customer satisfaction—rates exceeding 30% suggest strong service reliability.

What Are the Best API Production Line Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Avg. Response | Reorder Rate | Key Products | Price Range (Min Order) |

|---|---|---|---|---|---|---|---|

| Guangdong Shunyida Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | 100% | ≤1h | - | Automatic stuffing machines, multi-functional food lines | $15,444–16,855/set |

| Jiangsu Fushida Food Machinery Manufacturing Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | 100% | ≤2h | - | Peanut candy production lines | $11,000–12,000/set |

| Weishu Machinery Technology (Shanghai) Co., Ltd. | Shanghai, CN | Brand Holder | 93% | ≤4h | 41% | UHT milk lines, pasteurization systems, cheese automation | $23,000–100,000/set |

| Wuhan Daohe Intelligent Equipment Co., Ltd. | Hubei, CN | - | 100% | ≤1h | - | Colloid mills, semi-automatic food processing lines | $12,627–63,135/set |

| Huizhou Ruichuangying Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | 83% | ≤11h | <15% | Fully automatic paper can sealing lines | $11,000/set |

Performance Analysis

Guangdong- and Jiangsu-based suppliers demonstrate superior responsiveness and delivery consistency, with two manufacturers achieving 100% on-time fulfillment and sub-2-hour response times. Weishu Machinery stands out for after-sales loyalty, reflected in a 41% reorder rate, indicating robust system performance and technical support. While some suppliers offer lower entry prices (e.g., $11,000–12,000), higher-cost providers like Weishu deliver complex solutions involving thermal processing, automation integration, and hygienic design. Buyers should prioritize suppliers with documented experience in their specific product category—dairy, confectionery, or canned goods—to minimize rework and ensure regulatory alignment.

FAQs

How to verify API production line supplier credibility?

Request facility audit reports, machine test videos, and third-party inspection records. Validate certifications through official databases. Analyze transaction history for consistent order volume and repeat buyers. Direct engagement via video calls to assess technical team depth is recommended before contract signing.

What is the typical lead time for custom production lines?

Standard automated lines require 45–60 days from deposit confirmation. Complex integrations involving CIP/SIP systems, vision inspection, or robotic loading may extend timelines to 75–90 days. Expedited builds are possible with premium fees, reducing delivery by 10–15 days.

Do suppliers support global shipping and installation?

Yes, most established suppliers manage international freight under FOB, CIF, or DDP terms. Full container load (FCL) shipping is standard for complete lines. Many offer technician dispatch for on-site commissioning, though travel costs are typically borne by the buyer.

Are samples or pilot runs available?

Full-line sampling is uncommon due to scale, but suppliers often conduct trial runs using client-specified materials and provide recorded operation tests. Some offer modular demonstrations of individual units (e.g., filling head accuracy or sealing integrity) prior to full production release.

What customization options are commonly offered?

Suppliers routinely adjust line speed, product size, material contact surfaces (e.g., SS316 for corrosive media), control interface language, and packaging output format. Custom branding, CE marking, and integration with existing ERP/MES systems are also available upon request.