Apple Crates Bulk

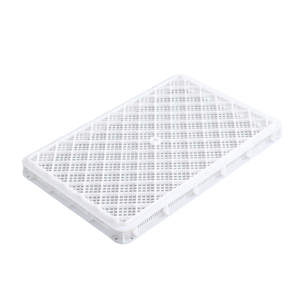

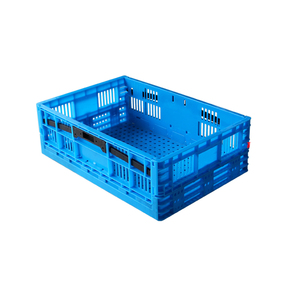

About apple crates bulk

Where to Find Apple Crates Bulk Suppliers?

China remains the global hub for industrial-grade apple crates in bulk, with concentrated manufacturing activity centered in Jiangsu, Shandong, and Shanghai regions. These clusters offer integrated supply chains combining plastic molding, metal reinforcement, and wood processing capabilities, enabling cost-efficient production of both stackable plastic and wooden crate variants. The proximity of raw material suppliers—particularly HDPE, PP resins, and sustainably sourced timber—reduces input costs by 15–25% compared to non-specialized regions.

Manufacturers in these zones operate vertically integrated facilities capable of high-volume output, supported by automated injection molding lines and CNC cutting systems for precision fabrication. Average monthly production capacity among verified suppliers exceeds 100,000 units, accommodating large-scale agricultural logistics demands. Buyers benefit from streamlined operations where design, prototyping, quality control, and packaging occur within single campuses, reducing lead times to 25–35 days for standard orders. This ecosystem supports flexible configurations in size, ventilation, nesting capability, and load-bearing strength tailored to fruit transport and cold chain distribution requirements.

How to Choose Apple Crates Bulk Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product reliability and supply chain continuity:

Material & Structural Compliance

Confirm use of food-grade polypropylene (PP) or high-density polyethylene (HDPE) compliant with FDA and EU 10/2011 standards for direct produce contact. For wooden crates, verify kiln-dried solid wood construction free from bark and pests, meeting ISPM-15 export regulations. Load testing documentation should confirm minimum static load capacities of 800kg and dynamic load tolerance up to 300kg for stacked configurations during transit.

Production Capacity Verification

Assess operational scale through key indicators:

- Facility area exceeding 3,000m² indicating industrial-scale production

- In-house mold development and plastic injection capabilities

- Nesting and folding mechanism integration for space-efficient designs

Cross-reference declared output volumes with on-time delivery performance (target ≥95%) and reorder rates as proxies for fulfillment consistency.

Customization and Transaction Security

Prioritize suppliers offering dimension, color, logo imprinting, and labeling customization validated through pre-production samples. Engage only with partners utilizing secure transaction frameworks such as third-party inspection services and payment escrow. Request verifiable records of past export shipments, particularly to North America, Europe, and Australia, to assess regulatory compliance proficiency.

What Are the Best Apple Crates Bulk Suppliers?

| Company Name | Location | Main Material | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jingli Pack Technology Jiangyin Co., Ltd. | Jiangsu, CN | Plastic (HDPE/PP) | 500–500 pcs | $3.50–7.50 | 100% | ≤2h | US $1,000+ | - |

| Chinapack Jingli Supply Chain Management Jiangyin Co., Ltd. | Jiangsu, CN | Plastic (Vented PP) | 5–100 pcs | $3.99–100 | 100% | ≤2h | US $220,000+ | - |

| Qingdao Enlightening Plast Co., Ltd. | Shandong, CN | HDPE/PP | 10–500 pcs | $3.10–90 | 100% | ≤3h | US $1,100,000+ | <15% |

| Shanghai Join Plastic Products Co,.ltd | Shanghai, CN | PP Mesh | 2–500 pcs | $4.00–12.00 | 92% | ≤1h | US $1,200,000+ | 20% |

| Jinan Hony Trading Co., Ltd. | Shandong, CN | Solid Wood | 300–500 pcs | $2.00–6.00 | 98% | ≤4h | US $80,000+ | 54% |

Performance Analysis

Jiangsu-based plastic crate manufacturers demonstrate consistent delivery performance (100% on-time) and competitive pricing below $8 per unit at scale. Qingdao Enlightening and Shanghai Join stand out for engineering flexibility, supporting full customization in color, dimensions, and branding with mold development support. Notably, Jinan Hony Trading excels in wooden crate supply, achieving a 54% reorder rate—the highest in the cohort—indicating strong customer retention despite longer response windows. While plastic crate suppliers dominate volume efficiency and nestability, wood-based solutions remain preferred for niche markets valuing aesthetics and biodegradability. Buyers seeking hybrid durability and returnable logistics models should prioritize suppliers with ISO-aligned quality management practices and documented field testing under humid, refrigerated conditions.

FAQs

How to verify apple crates bulk supplier reliability?

Validate compliance with material safety standards (FDA, EU 10/2011) and structural integrity claims through independent lab reports. Conduct virtual or physical factory audits focusing on mold maintenance, injection pressure controls, and finished goods inspection protocols. Analyze transaction history for dispute resolution patterns and shipment accuracy.

What is the typical sampling timeline for custom crates?

Standard sample production takes 7–14 days for existing molds. Custom tooling adds 15–25 days for mold creation. Air freight delivery to international destinations requires an additional 5–10 days. Expect partial or full sample cost recovery upon order confirmation, typically covering 30–50% of prototype expenses.

Can suppliers accommodate export packaging and labeling requirements?

Yes, leading suppliers provide export-standard packaging including palletization, stretch-wrapping, and moisture-resistant bundling. They also support custom labeling for barcodes, RFID tags, country-of-origin marking, and retailer-specific logistics codes. ISPM-15 certification is standard for wooden crate exporters.

Do manufacturers offer free samples?

Free samples are uncommon for bulk container products due to high material and tooling costs. However, many suppliers deduct sample fees from subsequent orders exceeding 500 units. For repeat buyers, complimentary samples may be issued for minor design iterations.

How to initiate customization for apple crates in bulk?

Submit detailed specifications including internal dimensions (L×W×H), required stack height, load capacity, vent hole pattern, nesting/folding mechanism preference, and surface finish. Reputable manufacturers respond with CAD drawings within 48 hours and deliver functional prototypes within 3 weeks for validation.