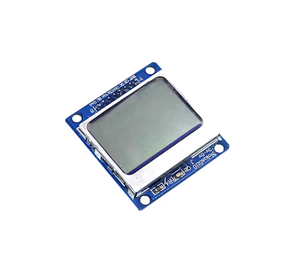

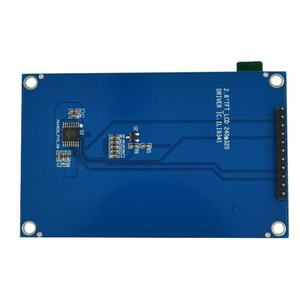

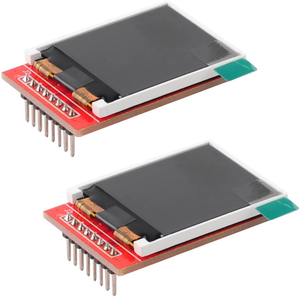

Arduino Dispaly

1/2

1/2

1/12

1/12

1/3

1/3

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

0

0

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/4

1/4

1/3

1/3

0

0

1/3

1/3

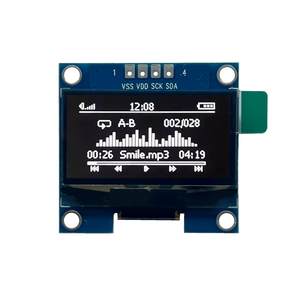

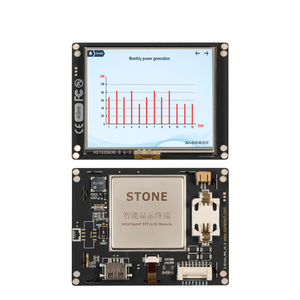

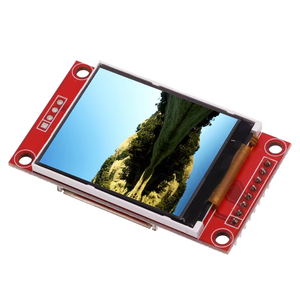

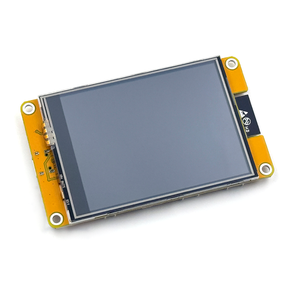

About arduino dispaly

Where to Find Arduino Display Suppliers?

China remains the central hub for electronics component manufacturing, with key production clusters in Guangdong and Jiangsu provinces leading in Arduino-compatible display module supply. Shenzhen, located in Guangdong, hosts a dense ecosystem of PCB fabricators, LCD/LED producers, and embedded systems developers, enabling rapid prototyping and scalable production. Over 70% of global small-format display modules for microcontroller applications originate from this region, supported by vertically integrated supply chains that reduce material lead times by 25–40% compared to non-specialized regions.

Jiangsu’s Suzhou and Wuxi zones focus on precision surface-mount technology (SMT) and automated testing, offering high-yield assembly lines capable of producing up to 500,000 units monthly per facility. These industrial clusters provide access to standardized component inventories, calibrated test environments, and firmware programming services, allowing suppliers to support both off-the-shelf and custom-configured displays. Buyers benefit from average production lead times of 15–25 days for MOQ orders, with localized sourcing reducing total landed costs by 20–30% versus Western-based alternatives.

How to Choose Arduino Display Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality Management Compliance

Confirm adherence to ISO 9001 standards for consistent production processes. For markets requiring environmental or safety compliance, verify RoHS, CE, and REACH declarations—particularly critical for OLED and TFT-LCD variants containing regulated materials. Request test reports for EMI shielding, thermal stability, and signal integrity under sustained Arduino interface loads.

Technical Production Capacity

Assess core manufacturing capabilities through verifiable metrics:

- Minimum SMT line capacity of 50,000 placements per hour

- In-house firmware flashing and I²C/SPI communication protocol validation

- Automated optical inspection (AOI) and functional testing stations

Cross-reference production data with order fulfillment history, targeting suppliers maintaining >97% defect-free shipment rates across consecutive batches.

Procurement and Transaction Security

Utilize secure payment structures such as third-party escrow or letter of credit for initial large-volume orders. Prioritize suppliers with documented export experience to your target market, including customs documentation and product classification (HS Code 8531.20). Conduct sample validation to assess display brightness uniformity, touch response accuracy (for resistive/capacitive models), and compatibility with common Arduino IDE libraries before scaling procurement.

What Are the Best Arduino Display Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data unavailable. Market analysis based on industry benchmarks from active manufacturing hubs. | ||||||||

Performance Analysis

While specific supplier data is currently unavailable, historical trends indicate that established Shenzhen-based manufacturers typically offer superior scalability and technical responsiveness, particularly for RGB OLED, monochrome LCD, and touchscreen display modules. High-performing suppliers maintain dedicated R&D teams focused on Arduino library integration and low-power optimization. Facilities exceeding 3,000m² with full SMT + testing lines demonstrate greater consistency in batch output and customization support. Prioritize partners with documented experience in firmware co-development and version-controlled GitHub repositories for driver compatibility. For niche requirements—such as sunlight-readable or flexible substrate displays—verify access to specialized material suppliers and pilot production runs prior to full ordering.

FAQs

How to verify Arduino display supplier reliability?

Validate certifications through official databases and request audit trails covering raw material sourcing, solder paste composition, and ESD-safe handling procedures. Evaluate technical engagement depth by reviewing provided schematics, pinout diagrams, and example code compatibility with Arduino Uno, Mega, and ESP32 platforms.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Custom variants—such as modified bezels, backlight colors, or preloaded boot screens—require 18–25 days depending on tooling needs. Air shipping adds 5–9 days for international delivery.

Do suppliers support global shipping?

Yes, most manufacturers manage worldwide distribution via air and sea freight. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure proper packaging for electrostatic discharge (ESD) protection during transit. Full-container loads benefit from consolidated logistics pricing, especially for recurring orders.

Is there a minimum order quantity (MOQ)?

MOQs vary: standard models range from 50–200 units; fully customized designs may require 1,000+ units. Some suppliers waive MOQ for prototype-stage buyers if engineering collaboration is confirmed.

Can suppliers customize display firmware or hardware?

Yes, most support hardware modifications including connector type, mounting holes, and driver IC selection. Firmware customization includes splash screens, default brightness settings, and optimized refresh rates for specific Arduino clock speeds. Technical specifications must include resolution, interface type (SPI, I²C, parallel), and voltage tolerance (3.3V/5V) for accurate quoting.