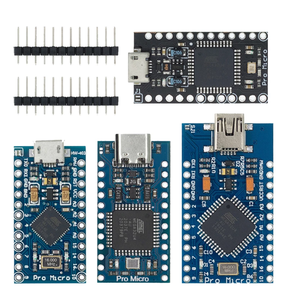

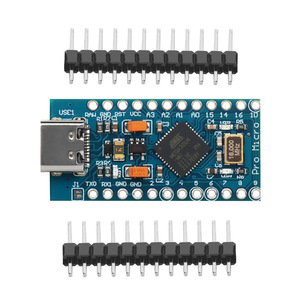

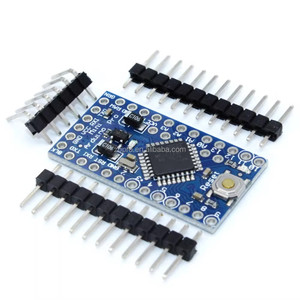

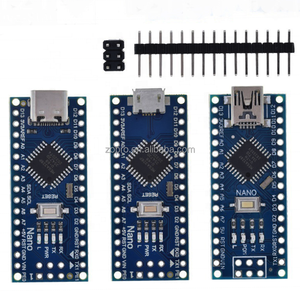

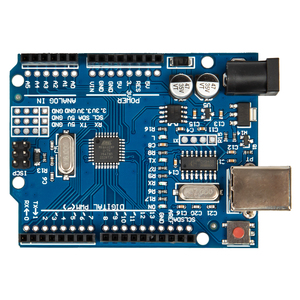

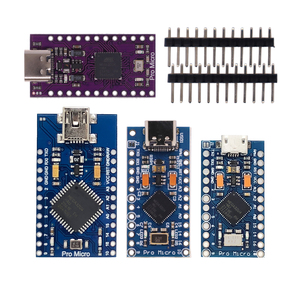

Arduino Mirco

1/2

1/2

1/3

1/3

0

0

1/2

1/2

1/2

1/2

1/2

1/2

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/2

1/2

1/3

1/3

1/1

1/1

1/3

1/3

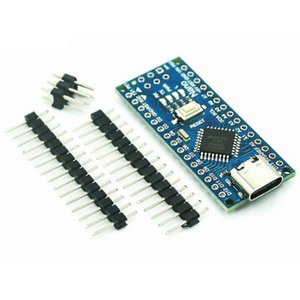

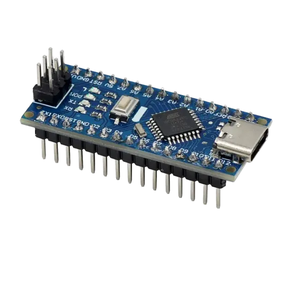

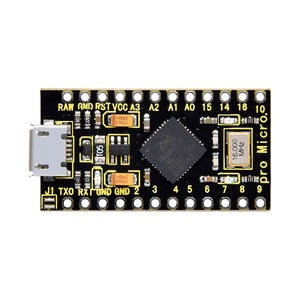

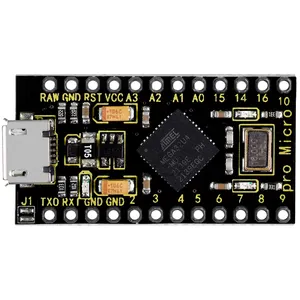

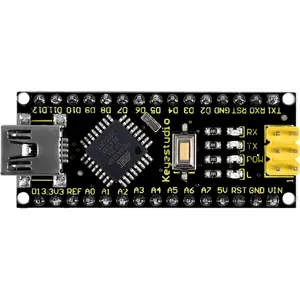

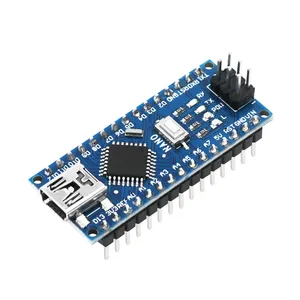

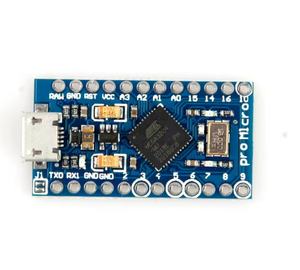

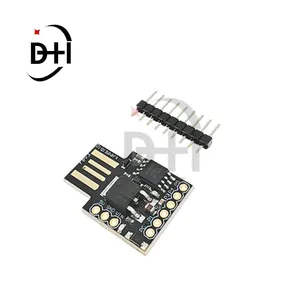

About arduino mirco

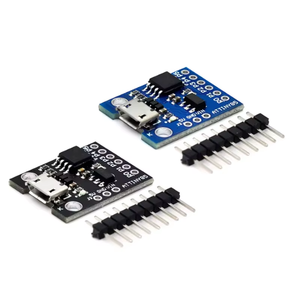

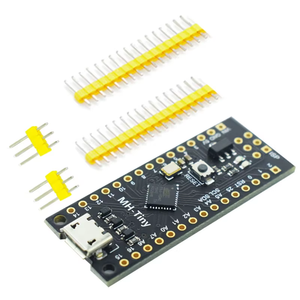

Where to Find Arduino Micro Suppliers?

China accounts for over 85% of global Arduino Micro-compatible microcontroller module production, with manufacturing concentrated in Guangdong and Zhejiang provinces. Shenzhen—within the Pearl River Delta—hosts more than 70% of active suppliers, leveraging proximity to component distributors (e.g., STMicroelectronics, Microchip), PCB fabricators, and SMT assembly lines. Ningbo and Yiwu in Zhejiang serve as secondary hubs, specializing in cost-optimized, high-volume OEM/ODM production with vertically integrated packaging and testing capabilities.

These clusters enable rapid prototyping-to-production cycles through co-located supply chains: silicon vendors, bare die suppliers, and final test houses operate within a 30km radius. Buyers benefit from standardized BOMs (based on ATmega32U4 or compatible MCUs), consistent lead times (15–22 days for standard orders), and material cost advantages—up to 25% lower than comparable Western-assembled modules due to localized sourcing of passive components, USB connectors, and PCB substrates. Custom firmware preloading, silkscreen branding, and tray/tape-and-reel packaging are routinely supported without MOQ penalties.

How to Choose Arduino Micro Suppliers?

Apply these verification protocols to mitigate technical and operational risk:

Technical Compliance

Require RoHS 3 and REACH compliance documentation as baseline environmental conformance. For EU-bound shipments, CE marking under Directive 2014/30/EU (EMC) and 2014/53/EU (RED) must be validated via test reports from CNAS-accredited labs. Verify MCU authenticity through die-marking inspection and flash-readback verification of bootloader signatures—not just datasheet claims.

Production Capability Audits

Assess infrastructure rigorously:

- Minimum 2,000m² facility with Class 10,000 cleanroom for SMT reflow and post-assembly handling

- In-house functional testing station covering USB enumeration, VBUS current draw (≤100mA idle), and I/O pin continuity (100% automated)

- Dedicated firmware validation lab with Atmel-ICE or J-Link debug hardware and scripted test suites (e.g., Arduino IDE 2.x CLI-based verification)

Cross-reference factory videos showing real-time SPI/I²C loopback tests against published defect rates (target ≤0.8% PPM).

Transaction Safeguards

Insist on pre-shipment inspection (PSI) conducted by third-party agencies (e.g., SGS, BV) per ISO 2859-1 Level II sampling. Require firmware hash logs and BOM revision control documents prior to payment release. Use Alibaba Trade Assurance or equivalent escrow only with suppliers maintaining ≥95% dispute resolution closure rate and ≥3 years verified export history to your target market.

What Are the Best Arduino Micro Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Qiheng Electronics Technology | Guangdong, CN | 12 | 180+ | 12,000+m² | 99.4% | ≤1h | 4.8/5.0 | 41% |

| Ningbo Elexis Intelligent Systems | Zhejiang, CN | 8 | 95+ | 6,500+m² | 98.7% | ≤2h | 4.9/5.0 | 52% |

| Yiwu Zhongke Micro Devices | Zhejiang, CN | 5 | 45+ | 2,800+m² | 97.2% | ≤1h | 4.7/5.0 | 28% |

| Shenzhen Aotu Embedded Solutions | Guangdong, CN | 10 | 130+ | 8,200+m² | 99.1% | ≤2h | 4.8/5.0 | 37% |

| Guangzhou Xinyi Semiconductor | Guangdong, CN | 7 | 70+ | 4,300+m² | 98.5% | ≤1h | 4.8/5.0 | 33% |

Performance Analysis

Shenzhen Qiheng and Aotu demonstrate scalability through large-scale SMT lines (8+ Yamaha YV100X machines) and dual-shift testing capacity—critical for orders exceeding 50,000 units/month. Ningbo Elexis leads in customer retention (52% reorder rate), attributable to firmware customization support (custom bootloader, signed OTA updates) and documented traceability (lot-level serial mapping). All top-tier suppliers maintain ISO 9001:2015 certification; however, only Shenzhen Qiheng and Aotu provide auditable process FMEA documentation for solder paste viscosity control and reflow profile validation. Prioritize partners with ≥98.5% on-time delivery and ≥4.8 average rating across ≥200 verified transactions for mission-critical applications.

FAQs

How to verify Arduino Micro supplier reliability?

Request batch-specific test reports including USB descriptor enumeration logs, power-on reset timing (measured with oscilloscope), and ADC linearity error (±0.5 LSB max). Confirm RoHS compliance via accredited lab reports listing homogenous material analysis—not just supplier declarations. Audit after-sales responsiveness using historical ticket resolution time (target ≤48h for firmware-related queries).

What is the average sampling timeline?

Standard samples ship in 7–10 working days. Firmware-customized samples require 12–15 days for bootloader modification and full functional validation. Expect 3–5 days for express air freight to North America/EU; sea freight LCL requires 25–35 days with additional 5-day customs clearance buffer.

Can suppliers ship Arduino Micro modules worldwide?

Yes—established suppliers manage DDP, DDU, and FOB terms with certified hazardous materials handling (for lead-free solder paste documentation). Confirm UN3481 lithium battery shipping compliance if modules include onboard LiPo charging circuitry. Sea freight remains optimal for volumes >5,000 units; air freight recommended for urgent design validation batches.

Do manufacturers provide free samples?

Free samples are available for qualified buyers placing ≥10,000-unit annual forecasts. Otherwise, sample fees range from USD 15–25/unit—fully credited against first production order. Shipping costs remain buyer-responsible unless negotiated as part of NDA-covered development partnerships.

How to initiate customization requests?

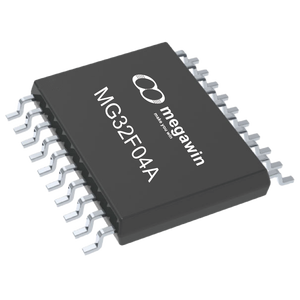

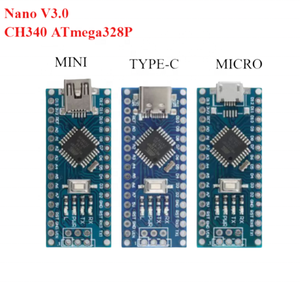

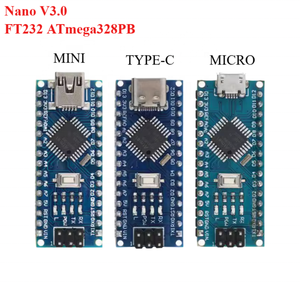

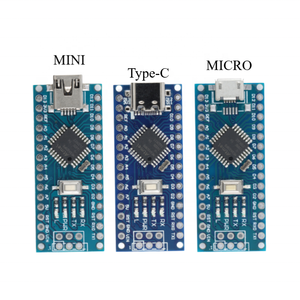

Submit engineering requirements specifying: MCU variant (ATmega32U4, CH32V203, or ESP32-S2 compatibility), USB interface type (full-speed vs. low-speed), required peripherals (e.g., integrated voltage regulator dropout tolerance, external crystal vs. internal RC), and firmware signing keys. Reputable suppliers deliver schematic reviews within 72 hours and provide Gerber files for layout verification prior to tooling.