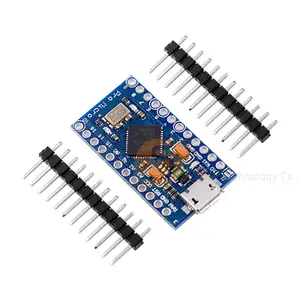

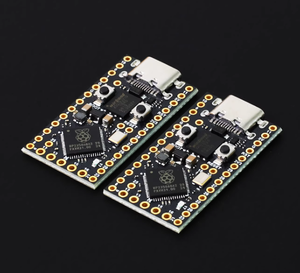

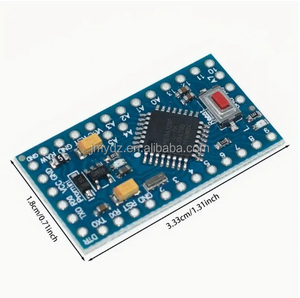

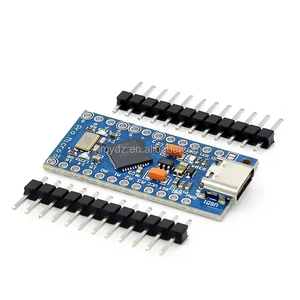

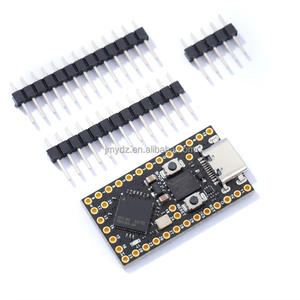

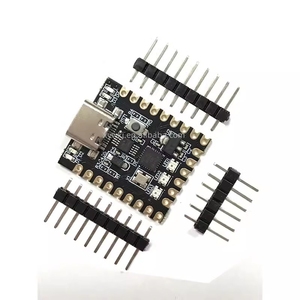

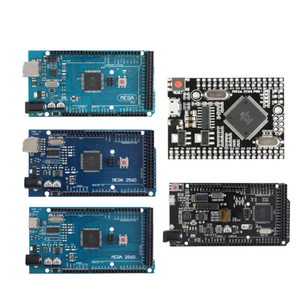

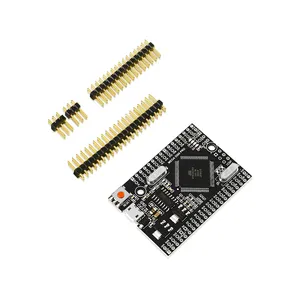

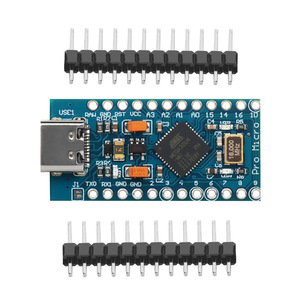

Arduino Promicro

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

1/2

1/2

0

0

1/13

1/13

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

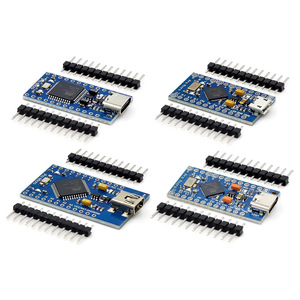

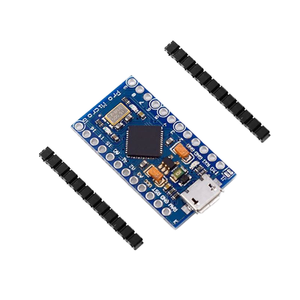

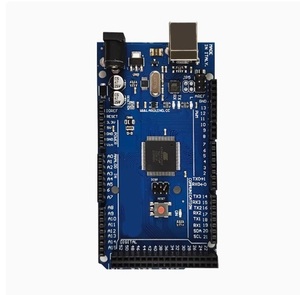

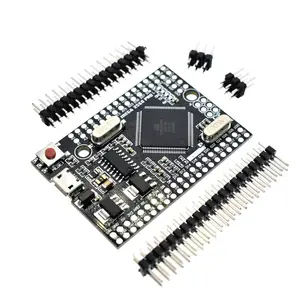

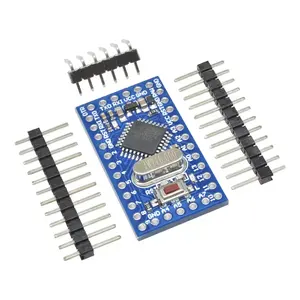

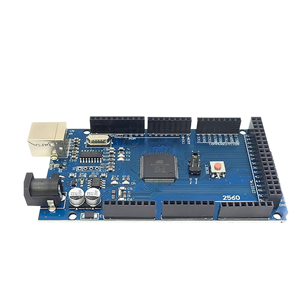

About arduino promicro

Where to Find Arduino Pro Micro Suppliers?

China remains the central hub for electronics manufacturing, with concentrated supplier networks in Guangdong and Jiangsu provinces driving production of compact microcontroller units like the Arduino Pro Micro. Shenzhen, located in Guangdong, hosts over 70% of China’s electronics component suppliers, supported by mature PCB fabrication clusters and rapid prototyping infrastructure. This region enables streamlined access to surface-mount technology (SMT) lines, reducing assembly lead times by up to 40% compared to non-specialized regions.

These industrial ecosystems benefit from vertically integrated supply chains—spanning IC sourcing, solder paste application, automated optical inspection (AOI), and functional testing—allowing for batch consistency and scalability. Buyers can expect typical production lead times of 15–25 days for standard orders, with cost advantages of 25–35% due to localized component availability and labor efficiency. The proximity of contract manufacturers, test engineers, and logistics providers within 30km enables agile fulfillment for both low-volume prototypes and high-volume deployments.

How to Choose Arduino Pro Micro Suppliers?

Procurement decisions should be guided by structured evaluation criteria:

Technical Compliance

Confirm adherence to international standards including RoHS and CE for electromagnetic compatibility and environmental safety. For integration into commercial devices, verify that boards use authentic ATmega32U4 microcontrollers and include proper USB descriptor implementation. Request documentation on BOM traceability and ESD protection measures during packaging.

Production Capability Audits

Assess operational capacity through verifiable metrics:

- Minimum SMT line throughput of 20,000 units per month

- In-house programming and flash verification systems

- Automated testing protocols for USB connectivity, reset functionality, and pin continuity

Cross-reference production videos with defect rates (target <0.8%) and order fulfillment history to validate reliability.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until product acceptance. Review supplier transaction records via verified channels, prioritizing those with documented quality dispute resolution processes. Pre-shipment sampling is critical—conduct firmware upload tests and voltage tolerance checks under load conditions before full-scale ordering.

What Are the Best Arduino Pro Micro Suppliers?

No supplier data available for comparative analysis.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on verifying technical authenticity and process maturity. Prioritize manufacturers demonstrating consistent output volume, clear compliance documentation, and responsive communication. Given the prevalence of counterfeit clones, direct validation of MCU origin and PCB layer quality (e.g., 2-layer FR4 construction) is essential. When feasible, request X-ray or cross-sectional images of finished boards to confirm internal trace integrity and solder joint reliability.

FAQs

How to verify Arduino Pro Micro supplier reliability?

Audit component sourcing practices, specifically confirmation of genuine Atmel/Microchip ICs through lot number tracing. Require evidence of functional testing procedures and inspect sample units for silkscreen accuracy, pad alignment, and board thickness (1.6mm standard). Validate supplier responsiveness and technical literacy through detailed inquiry handling.

What is the average sampling timeline?

Standard sample production typically takes 7–14 days, depending on component availability. Custom variants requiring modified pinouts or preloaded firmware may extend to 21 days. Air shipping adds 5–9 days for international delivery.

Can suppliers ship Arduino Pro Micro boards worldwide?

Yes, most manufacturers support global distribution via air or sea freight. Confirm Incoterm agreements (e.g., FOB Shenzhen, DDP) and ensure compliance with destination regulations regarding electronic imports. Electrostatic discharge (ESD)-safe packaging is standard for bulk shipments.

Do manufacturers provide free samples?

Sample policies vary. Established producers often waive fees for qualified buyers committing to minimum order quantities (typically 100+ units). For smaller requests, expect to cover material and handling costs, usually ranging from $10–$25 per unit.

How to initiate customization requests?

Submit detailed specifications including PCB color, bootloader configuration, firmware version, and marking requirements. Leading suppliers offer customized silkscreen, pre-flashed code, and variant-specific packaging. Prototype delivery for modified designs typically occurs within 3–4 weeks following design approval.