Arduino Rotary Encoder

Top sponsor listing

Top sponsor listing

1/2

1/2

1/4

1/4

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/46

1/46

1/3

1/3

0

0

0

0

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

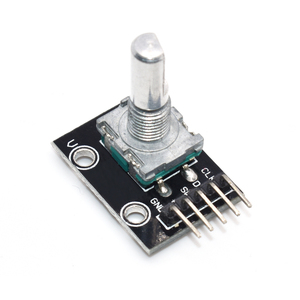

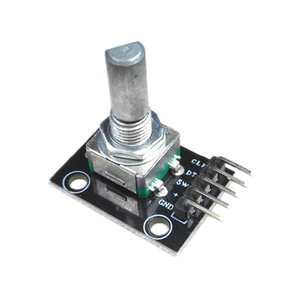

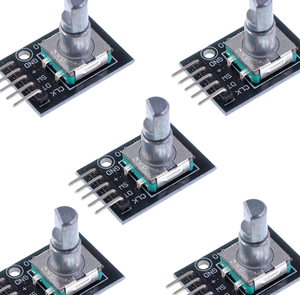

About arduino rotary encoder

Where to Find Arduino Rotary Encoder Suppliers?

China remains the central hub for electronic component manufacturing, with concentrated supplier networks in Guangdong and Zhejiang provinces driving production efficiency for Arduino-compatible rotary encoders. Guangdong, particularly within the Pearl River Delta region, hosts over 70% of China’s electronics OEMs, supported by Shenzhen’s advanced prototyping infrastructure and rapid PCB assembly capabilities. This ecosystem enables streamlined integration of encoder modules with microcontroller platforms, reducing development cycles for end-users.

These industrial clusters benefit from vertically integrated supply chains—encompassing precision machining, surface-mount technology (SMT), and automated testing—allowing suppliers to maintain tight tolerances in switch actuation and quadrature signal output. Buyers gain access to scalable production environments where lead times for standard encoder units average 15–25 days, with cost advantages of 25–40% compared to European or North American alternatives due to localized component sourcing and labor efficiency. Custom configurations, including detent adjustments, LED integration, or shaft length modifications, are routinely accommodated within existing production lines.

How to Choose Arduino Rotary Encoder Suppliers?

Procurement decisions should be guided by systematic evaluation criteria to ensure technical reliability and supply chain continuity:

Quality Management Standards

Confirm adherence to ISO 9001 for consistent quality control processes. For applications involving consumer electronics or educational kits, RoHS and REACH compliance is essential to meet environmental regulations in target markets. Request test reports verifying electrical durability (typically rated for 20,000–50,000 cycles) and signal stability under variable rotation speeds.

Production Capability Assessment

Evaluate key operational indicators:

- Minimum monthly output capacity exceeding 100,000 units to support volume orders

- In-house SMT and DIP assembly lines with automated optical inspection (AOI)

- Access to CNC machining for custom encoder shafts and housings

Cross-reference production data with on-time delivery performance (target >97%) to validate scalability and inventory management.

Technical and Transactional Safeguards

Require sample validation before bulk ordering, focusing on mechanical feel, rotational accuracy, and compatibility with common Arduino libraries (e.g., Encoder.h). Utilize third-party inspection services for pre-shipment audits when sourcing beyond established partners. Prioritize suppliers with documented export experience to your region, particularly those familiar with IEC 60669-2-1 standards for rotating controls. Escrow-based payment terms reduce financial risk during initial engagements.

What Are the Best Arduino Rotary Encoder Suppliers?

No supplier data available for comparative analysis.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on verifying production infrastructure and compliance documentation directly through audit questionnaires and sample evaluations. Regions like Shenzhen and Ningbo are known for high concentrations of electronics manufacturers capable of low-MOQ trials (as low as 100–500 units), making them ideal for prototype validation. As demand scales, shift toward suppliers with demonstrated batch consistency and ERP-integrated quality tracking systems to minimize defect rates in mass deployment scenarios.

FAQs

How to verify Arduino rotary encoder supplier reliability?

Validate certifications through official databases and request factory audit reports covering incoming material inspection, process control, and final testing procedures. Assess responsiveness and technical competence through engineering inquiries related to bounce time, pull-up resistor configuration, or pulse per rotation (PPR) accuracy.

What is the typical sampling timeline?

Standard encoder samples are typically produced within 5–10 working days. Custom variants requiring modified shafts or integrated LEDs may require 15–20 days depending on tooling needs. Air shipping adds 5–8 days for international delivery.

Can suppliers ship Arduino rotary encoders worldwide?

Yes, most manufacturers support global logistics via air or sea freight. Confirm Incoterms (FOB, CIF, DDP) during quotation and verify compliance with destination electronics import regulations, especially for shipments into the EU or U.S. where conformity marking and customs documentation are mandatory.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer one free sample per inquiry for qualified buyers, especially if followed by a purchase commitment. For customized prototypes, expect full cost recovery unless MOQ thresholds (typically 1,000+ units) are met in subsequent orders.

How to initiate customization requests?

Submit detailed specifications including shaft diameter (6mm standard), total height, detent count (12, 20, or continuous), PPR (typically 20), and circuit requirements (common cathode/anode, inclusion of switch). Reputable suppliers respond with CAD drawings or 3D models within 72 hours and deliver functional prototypes in 2–3 weeks.