Arduino Wholesale

1/1

1/1

1/3

1/3

1/8

1/8

1/1

1/1

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

1/4

1/4

1/13

1/13

0

0

0

0

0

0

0

0

1/3

1/3

About arduino wholesale

Where to Find Arduino Wholesale Suppliers?

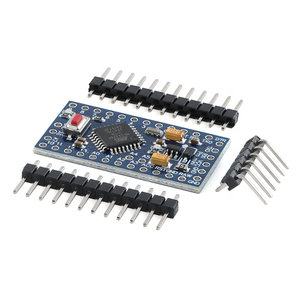

China remains the central hub for electronics manufacturing, with established industrial clusters in Guangdong and Zhejiang provinces leading production of microcontroller-based products such as Arduino-compatible boards. Shenzhen, located in Guangdong, hosts a dense ecosystem of electronics OEMs and component suppliers, enabling rapid prototyping and scalable assembly. Over 70% of global low-to-mid-tier microcontroller units are produced within this region, supported by mature PCB fabrication, surface-mount technology (SMT) lines, and automated testing infrastructure.

These manufacturing zones offer integrated supply chains where raw materials—FR-4 substrates, ATmega328P and ESP32 chips, passive components—are sourced within localized networks, reducing material lead times by up to 40%. Production facilities typically operate under ISO 9001 quality management systems, with many achieving RoHS and CE compliance for export markets. Buyers benefit from modular production setups capable of fulfilling both standard wholesale orders (MOQs from 50–500 units) and customized variants with preloaded firmware or modified pin layouts. Average lead times range from 15 to 30 days, depending on order complexity and component availability.

How to Choose Arduino Wholesale Suppliers?

Procurement decisions should be guided by structured supplier evaluation protocols:

Quality & Compliance Verification

Confirm adherence to international standards including RoHS (restriction of hazardous substances) and CE marking for electromagnetic compatibility. For integration into commercial or educational products, ensure boards undergo ESD protection testing and voltage tolerance validation. Request test reports for key parameters such as clock stability, analog-to-digital converter accuracy, and power consumption under load.

Production Capacity Assessment

Evaluate operational scale through verifiable metrics:

- Minimum 2,000m² facility with dedicated SMT and through-hole assembly lines

- In-house programming stations for bootloader flashing and functional testing

- Automated optical inspection (AOI) systems to reduce defect rates below 200 PPM (parts per million)

Cross-reference production capacity with order history, targeting suppliers maintaining >95% on-time delivery performance.

Customization & Transaction Security

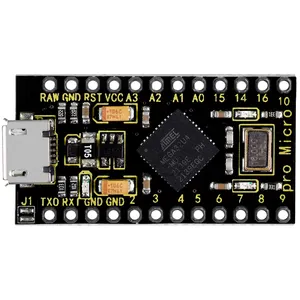

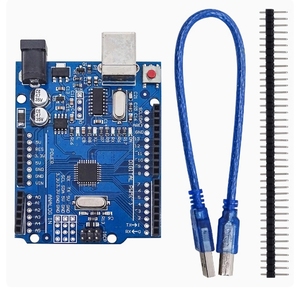

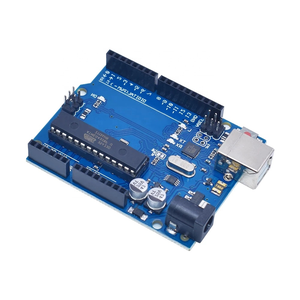

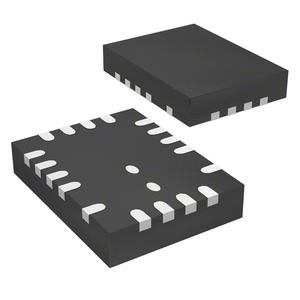

Assess flexibility for firmware customization, branding (silk-screened logos), and bundled accessories (cables, shields). Require secure transaction frameworks—preferably third-party escrow or letter of credit arrangements—for initial large-volume orders. Validate sample performance against reference Arduino UNO or Nano specifications before scaling procurement. Benchmark boot success rate across 100+ power cycles and verify USB-to-serial chip authenticity (e.g., genuine CH340G vs. clones).

What Are the Best Arduino Wholesale Suppliers?

No supplier data is currently available for analysis. Procurement professionals are advised to conduct direct factory audits or engage independent inspection services when evaluating new partners. Prioritize manufacturers with documented export experience to North America and EU regions, as compliance requirements in these markets necessitate rigorous quality control processes. Video tours of production floors, solder reflow profiles, and ESD-safe handling procedures serve as critical due diligence tools.

Performance Analysis

In absence of specific supplier records, sourcing strategy should emphasize risk mitigation through phased sampling and incremental order scaling. Suppliers demonstrating transparent documentation, consistent product revision control, and responsive technical communication typically present lower onboarding risk. Given the prevalence of counterfeit ICs in the market, insist on component traceability from authorized distributors such as Digi-Key, Mouser, or Arrow for critical microchips.

FAQs

How to verify Arduino wholesale supplier reliability?

Validate certifications through issuing bodies and request batch-specific compliance documentation. Conduct unannounced audits or hire third-party inspection firms to assess production practices. Analyze customer feedback focusing on long-term board reliability, firmware consistency, and post-sale technical support responsiveness.

What is the average sampling timeline?

Standard sample production takes 7–14 days, including PCB assembly, programming, and basic functionality checks. Custom configurations requiring unique PCB designs or firmware development may require 20–30 days. Air shipping adds 5–10 days for international delivery.

Can suppliers ship Arduino boards worldwide?

Yes, most established manufacturers support global logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm proper packaging for electrostatic discharge protection and compliance with IATA regulations for lithium battery-containing shipments if batteries are included in kits.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer one paid sample to cover material and labor costs, refundable against first bulk orders above 200 units. Fully free samples are uncommon due to embedded component value, particularly for boards using authentic MCU chips.

How to initiate customization requests?

Submit detailed technical requirements including target form factor, MCU type (ATmega, ESP32, SAMD), required peripherals (Wi-Fi, BLE, motor drivers), and firmware specifications. Reputable suppliers will provide schematic reviews, gerber file confirmations, and prototype units within 3–4 weeks for validation.