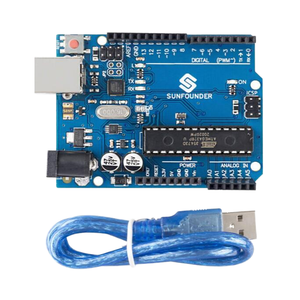

Arduino With Display

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/12

1/12

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/2

1/2

1/1

1/1

1/8

1/8

1/3

1/3

0

0

0

0

0

0

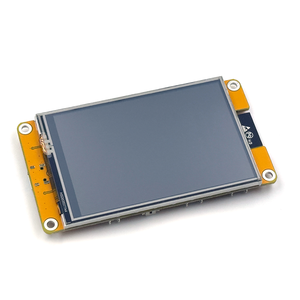

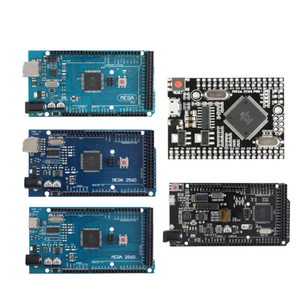

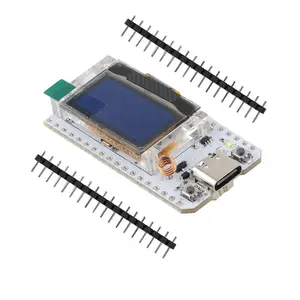

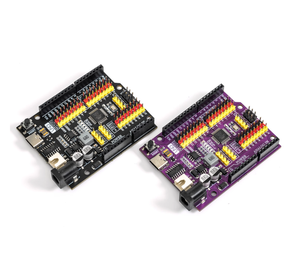

About arduino with display

Where to Find Arduino with Display Suppliers?

China remains the central hub for electronics manufacturing, particularly in the development and production of integrated microcontroller solutions such as Arduino boards with built-in or bundled displays. Key industrial clusters in Guangdong Province—centered around Shenzhen and Dongguan—leverage advanced surface-mount technology (SMT) lines and proximity to semiconductor supply chains to deliver high-volume, cost-competitive units. These regions host over 70% of China’s consumer electronics OEMs, supported by mature ecosystems integrating PCB fabrication, component sourcing, and rapid prototyping.

Suppliers in these zones benefit from vertically integrated operations, enabling end-to-end control from design to final assembly. This integration reduces lead times for standard configurations to 25–35 days and supports flexible order scaling, with many facilities capable of monthly outputs exceeding 50,000 units. Localized access to key materials—including ATmega328P/ESP32 microcontrollers, OLED/LCD modules, and FR-4 substrates—reduces material procurement cycles by up to 40% compared to non-specialized regions. Buyers also gain logistical advantages through Shenzhen’s port infrastructure, facilitating efficient air and sea freight options for global distribution.

How to Choose Arduino with Display Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Quality & Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management and RoHS compliance for hazardous substance restrictions. For commercial deployments in regulated markets (EU, North America), CE and FCC certifications are mandatory to ensure electromagnetic compatibility and product safety. Request test reports validating signal integrity, power efficiency, and display interface stability under variable load conditions.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum 2,000m² production area with dedicated SMT and DIP assembly lines

- In-house programming and testing stations for firmware flashing and functional validation

- R&D teams comprising at least 8–12% of total staff to support customization

- Monthly output capacity ≥30,000 units to ensure scalability

Cross-reference declared capabilities with historical order fulfillment data, targeting suppliers with documented on-time delivery rates above 97%. Facility walkthrough videos showing automated optical inspection (AOI) systems and ESD-safe workstations provide additional confidence in process rigor.

Procurement Risk Mitigation

Utilize secure transaction models such as third-party escrow until post-delivery quality verification is completed. Prioritize suppliers with verifiable export experience to your target market, particularly those familiar with customs documentation for electronic kits and educational hardware. Pre-shipment sampling is critical—test sample units against key performance indicators including boot time consistency, display refresh rate, and I/O pin accuracy before committing to bulk orders.

What Are the Best Arduino with Display Suppliers?

No supplier data is currently available for analysis.

Performance Analysis

In the absence of specific supplier profiles, buyers should focus on regional strengths when initiating sourcing campaigns. Shenzhen-based manufacturers typically offer faster turnaround due to dense component availability and agile logistics, while Dongguan suppliers often provide better pricing for large-volume runs owing to larger factory footprints and automation investments. When evaluating new partners, prioritize transparency in bill-of-materials (BOM) sourcing and willingness to undergo remote or on-site audits. For applications requiring long-term support, verify firmware update policies and component lifecycle management practices to mitigate obsolescence risks.

FAQs

How to verify Arduino with display supplier reliability?

Validate certifications through official databases and request audit trails covering incoming component inspection, in-process testing, and final QA procedures. Analyze customer feedback focusing on defect rates, communication responsiveness, and after-sales technical support. Where possible, conduct video audits of production lines to observe real-time quality controls.

What is the average sampling timeline?

Standard samples take 10–18 days to produce, depending on configuration complexity. Units with custom preloaded firmware or modified PCB layouts may require 25–30 days. Add 5–9 days for international express shipping. Some suppliers offer expedited 7-day sampling for validated buyers at a premium cost.

Can suppliers ship Arduino with display units worldwide?

Yes, most established manufacturers support global shipping via air, sea, or express courier. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam) during quotation and verify that packaging meets ISTA 3A standards for electronic goods. Ensure suppliers can generate necessary export documentation, including commercial invoices, packing lists, and HS code classification (typically 8542.31 or 8517.62).

Do manufacturers provide free samples?

Free samples are uncommon for fully assembled Arduino-display units due to component costs. However, suppliers may waive fees for repeat customers or offset sample charges against future orders exceeding 500 units. Typical sample costs range from $15–$35 per unit, covering BOM and labor expenses.

How to initiate customization requests?

Submit detailed specifications including microcontroller type (ATmega328P, ESP32, etc.), display type (OLED, TFT, LCD), resolution, power input requirements, and desired firmware features. Leading suppliers will return schematic proposals, Gerber files, and 3D renderings within 5–7 business days, followed by prototype builds in 3–4 weeks.