Arm Cortex A53

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/23

1/23

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/2

1/2

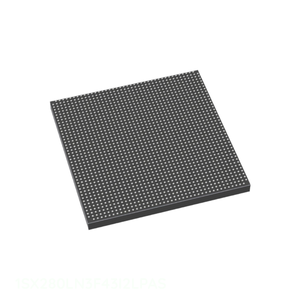

About arm cortex a53

Where to Find ARM Cortex-A53 Suppliers?

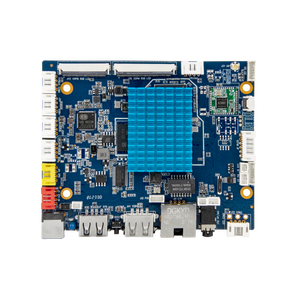

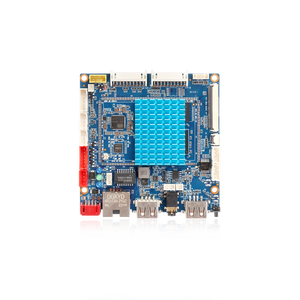

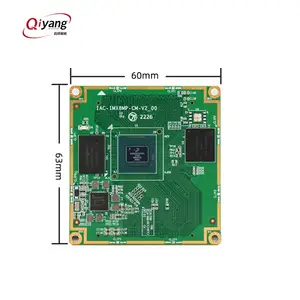

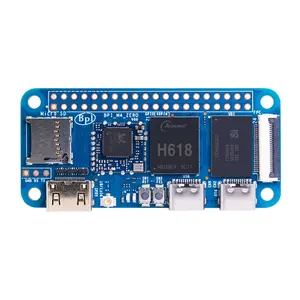

The global supply of ARM Cortex-A53-based semiconductor solutions is concentrated in East Asia, with China, Taiwan, and South Korea hosting the majority of design houses and contract manufacturers. Within China, industrial clusters in Shanghai, Shenzhen, and Beijing have emerged as key hubs for embedded systems and System-on-Chip (SoC) development leveraging the Cortex-A53 architecture. These regions benefit from dense ecosystems integrating IC design firms, foundry partners, and electronics manufacturing services (EMS), enabling rapid prototyping and volume production.

Shenzhen’s Huaqiangbei district serves as a distribution nexus for components incorporating Cortex-A53 cores, including application processors from Allwinner, Rockchip, and MediaTek. The city's proximity to Tier-1 EMS providers allows for seamless integration into finished products such as set-top boxes, industrial controllers, and IoT gateways. Meanwhile, Shanghai hosts several ARM-authorized design centers and fabless semiconductor companies that license the Cortex-A53 core for custom SoC development, supported by local access to 12-inch wafer testing and packaging facilities. This regional specialization enables lead times as low as 4–6 weeks for pre-certified modules and accelerates time-to-market for derivative designs.

How to Choose ARM Cortex-A53 Suppliers?

Selecting reliable suppliers requires rigorous technical and operational due diligence:

Design & Compliance Validation

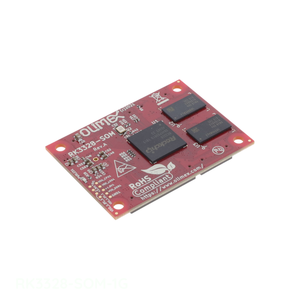

Confirm adherence to ARM architectural licensing requirements. Suppliers must provide evidence of valid ARM processor licenses and compliance with AMBA interface standards. For commercial and industrial applications, verify RoHS and REACH compliance. Consumer-grade SoCs should meet applicable safety certifications such as FCC Part 15 or CE EMC directives.

Manufacturing & Integration Capability

Assess backend production infrastructure through documented audits:

- Minimum 8-layer PCB assembly support for high-density routing

- In-house firmware flashing and burn-in testing capabilities

- Access to accredited third-party labs for thermal, signal integrity, and EMI validation

Prioritize suppliers offering full traceability across BOM components, particularly for DRAM and power management ICs co-used with Cortex-A53 SoCs.

Supply Chain Resilience & Transaction Security

Evaluate component lifecycle status—ensure no use of end-of-life (EOL) or counterfeit silicon. Require Lot tracking numbers and date-code transparency. Utilize escrow payment terms until batch verification is completed at destination. Cross-reference supplier claims against independent distributor platforms for consistency in delivery performance and return material rates.

What Are the Best ARM Cortex-A53 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

Performance Analysis

Due to absence of verified supplier data, procurement teams should focus on established semiconductor distributors and authorized design partners. Leading vendors typically operate ISO 9001-certified workflows with dedicated product longevity programs ensuring Cortex-A53-based chips remain available for 7+ years post-launch. High-performing partners demonstrate reorder rates above 30%, indicating strong customer retention driven by stable firmware updates, long-term BOM control, and responsive technical support. Prioritize those offering reference designs, SDK access, and Linux BSP maintenance for faster integration cycles.

FAQs

How to verify ARM Cortex-A53 supplier reliability?

Validate ARM IP licensing status through official partner directories. Request test reports for operating temperature range, power consumption under load, and boot cycle endurance. Review supplier history for product discontinuations and assess availability of pin-to-pin compatible alternatives.

What is the average sampling timeline?

Evaluation kits and engineering samples are typically dispatched within 5–10 business days. Custom carrier board designs require 3–5 weeks for fabrication and pre-production testing. Allow additional 7–14 days for international shipping depending on region.

Can suppliers ship globally?

Yes, most semiconductor suppliers support worldwide distribution via DDP or FCA Incoterms. Confirm export controls compliance, especially for dual-use technologies. Shipments to regulated markets may require ECCN classification (e.g., 3A991.b.1 for general-purpose microprocessors).

Do manufacturers provide free samples?

Sample policies vary by vendor scale. Large semiconductor firms often offer limited free samples for qualified developers. Smaller design houses may charge nominal fees recoverable against future orders. Development boards are frequently discounted but rarely provided at zero cost.

How to initiate customization requests?

Submit detailed requirements including clock frequency targets, memory configuration (LPDDR3/DDR4), I/O interface needs (USB 3.0, Gigabit Ethernet), and thermal envelope constraints. Reputable suppliers respond with feasibility assessments within 72 hours and deliver preliminary schematics in 1–2 weeks.