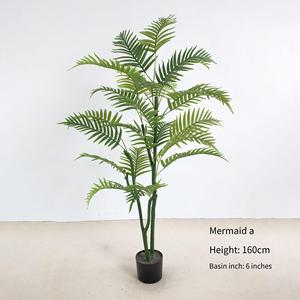

Artificial Tree Outside

1/20

1/20

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/6

1/6

1/19

1/19

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/17

1/17

1/11

1/11

1/3

1/3

About artificial tree outside

Where to Find Artificial Tree Outside Suppliers?

China remains the leading global manufacturing hub for artificial outdoor trees, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities specializing in weather-resistant polymer processing, metal framing, and UV-stabilized foliage assembly. Zhejiang’s Ningbo and Yiwu zones account for over 50% of China’s decorative landscaping exports, leveraging proximity to deep-water ports for efficient international distribution.

Manufacturers in these industrial bases utilize advanced injection molding and powder-coated steel fabrication to produce durable, all-weather artificial trees designed for commercial and municipal applications. Integrated supply chains enable localized sourcing of raw materials such as polyethylene (PE), polyvinyl chloride (PVC), and galvanized steel supports—reducing material costs by 18–25% compared to Western-based producers. Buyers benefit from consolidated ecosystems where design, tooling, production, and packaging operations are co-located within 30km radii, supporting lead times of 25–40 days for standard orders and MOQs as low as 10 units.

How to Choose Artificial Tree Outside Suppliers?

Implement structured evaluation criteria to ensure product durability, compliance, and supply chain reliability:

Material & Environmental Compliance

Confirm use of UV-inhibited PE or PVC foliage rated for minimum 3-year colorfastness under ASTM G154 accelerated weathering standards. For public installations, verify RoHS and REACH compliance for heavy metal content. Outdoor-rated trees must incorporate flame-retardant additives meeting Class B fire ratings per ASTM E84.

Structural Integrity Verification

Assess core construction specifications:

- Steel trunks with wall thickness ≥2.0mm and anti-corrosion coating (zinc + epoxy primer)

- Base mounting systems suitable for ground embedment or weighted surface installation

- Modular branch assemblies allowing field servicing and replacement

Validate structural load testing reports, particularly for tall models (≥3m) exposed to wind loads up to 60 km/h.

Production and Quality Assurance

Prioritize suppliers with ISO 9001-certified quality management systems. On-site audits should confirm in-house mold development, robotic spraying stations, and batch traceability protocols. Request third-party inspection reports (e.g., SGS or Intertek) covering dimensional accuracy, finish adhesion, and salt spray resistance (minimum 480 hours). Evaluate reorder rates and on-time delivery performance as indicators of operational stability.

What Are the Best Artificial Tree Outside Suppliers?

No supplier data is currently available for this category.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on verifying technical documentation and material certifications. Emphasis should be placed on manufacturers demonstrating proven export experience to temperate and tropical climates, where UV exposure and humidity present greater durability challenges. When data becomes available, comparative analysis will prioritize factory scale (minimum 3,000m²), engineering capacity, and compliance with international safety and environmental standards.

FAQs

How to verify artificial tree durability for outdoor use?

Request test reports validating UV resistance, colorfastness, and structural integrity under simulated environmental stress. Insist on real-world installation references in comparable climatic zones. Physical samples should undergo 30-day open-air exposure trials before bulk ordering.

What is the typical lead time for custom artificial trees?

Standard models require 25–35 days post-deposit. Custom designs involving unique canopy shapes, non-standard heights (4m+), or specialized finishes extend lead times to 45–60 days, including prototype approval cycles.

Can suppliers accommodate low-volume or sample orders?

Most manufacturers accept trial orders of 1–5 units at 1.5–2x unit cost. Sample fees are typically waived upon placement of full production runs exceeding 20 units. Air freight shipping adds 7–12 days for international delivery.

What customization options are commonly available?

Reputable suppliers support modifications in height (1.5m–8m), trunk texture (bark-molded, smooth, twisted), foliage density (measured in tips per meter), and color blending (e.g., seasonal variegation). CAD drawings and 3D visualizations are usually provided within 5 business days of specification submission.

What are standard packaging and shipping methods?

Trees are typically disassembled into trunk sections, branches, and base components, packed in reinforced cartons with foam protection. Flat-pack configurations optimize container loading, enabling 8–12 units per 20ft FCL. Crated options are available for high-value or oversized installations requiring lift equipment during deployment.