Assembly And Fabrication

Top sponsor listing

Top sponsor listing

About assembly and fabrication

Where to Find Assembly and Fabrication Service Suppliers?

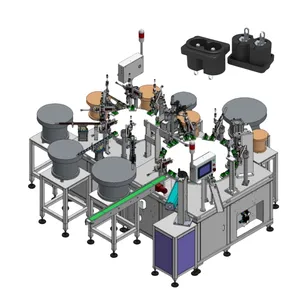

China remains a global hub for industrial assembly and fabrication services, with key manufacturing clusters in Guangdong, Fujian, and Shandong provinces. These regions host vertically integrated facilities that combine design, component sourcing, and production under one roof, enabling streamlined one-stop solutions. Dongguan and Shenzhen in Guangdong specialize in automation equipment and electronics assembly, supported by dense ecosystems of PCB and motor manufacturers. Xiamen in Fujian has emerged as a center for battery and industrial machinery fabrication, while Shandong’s laser technology firms support high-precision metal processing and customized production lines.

The concentration of suppliers in these zones enables economies of scale, localized supply chains, and rapid prototyping capabilities. Facilities typically operate dedicated production lines for automated assembly, with average lead times ranging from 30 to 60 days depending on complexity. Buyers benefit from cost efficiencies—up to 25–40% lower than Western counterparts—due to reduced logistics overhead and access to in-house machining, welding, coating, and testing infrastructure within 50 km supplier radii.

How to Choose Assembly and Fabrication Service Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Production Capability Assessment

Prioritize suppliers with documented in-house production lines and engineering teams capable of end-to-end project execution. Key indicators include:

- Ownership of automated assembly or PLC-controlled production systems

- Capacity for customization (e.g., material, color, size, labeling, graphic integration)

- Minimum factory area supporting batch or continuous production runs

Cross-reference product listings and service descriptions with delivery performance metrics to assess scalability and consistency.

Quality and Compliance Verification

Confirm adherence to international quality benchmarks through verifiable data points. While formal certifications (ISO 9001, CE, RoHS) are not explicitly stated in available records, operational reliability can be inferred from:

- On-time delivery rates ≥97%

- Response times ≤6 hours (preferably ≤2h)

- Reorder rates above 25%, indicating customer retention and satisfaction

High-performing suppliers maintain response efficiency and consistent output, critical for time-sensitive industrial procurement.

Transaction Risk Mitigation

Implement safeguards prior to order placement:

- Require detailed technical specifications and validation of customization scope

- Utilize secure payment mechanisms tied to milestone deliveries

- Request sample units or facility documentation before full commitment

Analyze online revenue trends and product listing diversity as proxies for business stability and market demand absorption.

What Are the Best Assembly and Fabrication Service Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Notable Product Range |

|---|---|---|---|---|---|---|---|---|

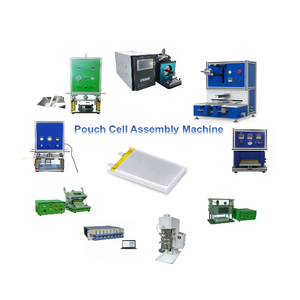

| Xiamen Tmax Battery Equipments Limited | Fujian, CN | Other Machinery & Industrial Equipment (921) | 88% | ≤6h | <15% | US $130,000+ | Color, material, size, logo, packaging, label, graphic | Battery pack lines, coating & grinding equipment |

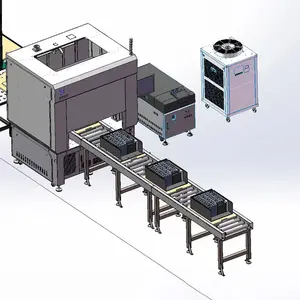

| Shandong Huiyao Laser Technology Co., Ltd. | Shandong, CN | Data not available | 66% | ≤2h | <15% | US $10,000+ | Factory customization supported | Lithium battery production lines, EV battery systems |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Other Machinery & Industrial Equipment (342) | 100% | ≤6h | - | - | PLC control, motor type, layout design | Circuit breaker lines, AC/DC motors, automation systems |

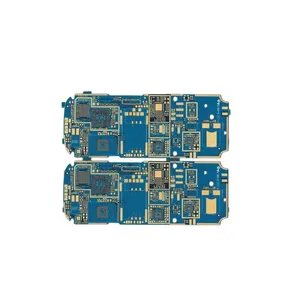

| Shenzhen Kingfung Technology Co., Ltd. | Guangdong, CN | PCBA (125) | 100% | ≤4h | 28% | US $9,000+ | One-stop PCB assembly, BMS, drive boards | Industrial control boards, solar inverters, energy storage |

| Shenzhen Yongkefeng Technology Co., Ltd. | Guangdong, CN | PCBA (327) | 100% | ≤1h | 25% | US $70,000+ | Design, clone, multilayer PCB, electronic product development | PCB design, electronic manufacturing, FR4 boards |

Performance Analysis

Suppliers like Dongguan Yicheng and Shenzhen-based firms demonstrate strong operational reliability with 100% on-time delivery and robust customization frameworks. Shenzhen Kingfung and Yongkefeng stand out in electronics-focused assembly, offering one-stop PCBA and embedded system fabrication with high reorder rates (25–28%), reflecting client trust in technical execution. Xiamen Tmax exhibits broad industrial reach with over 900 equipment listings but shows lower repeat order activity, suggesting potential gaps in post-sale engagement or niche specialization.

Shandong Huiyao offers large-scale lithium battery line solutions priced up to $1.5 million per set, yet its 66% on-time delivery rate presents a notable risk for time-critical deployments. In contrast, Shenzhen Yongkefeng combines rapid ≤1-hour response times with extensive PCB expertise, making it ideal for fast-turnaround electronic subassembly projects. Buyers seeking automation lines should prioritize Guangdong and Fujian suppliers with proven track records in circuit breakers, motors, or battery systems.

FAQs

How to verify assembly and fabrication supplier reliability?

Evaluate on-time delivery history, response speed, and reorder rate as proxies for service consistency. Request technical documentation, process flowcharts, or video audits of production lines. Assess customization depth through sample requests and specification reviews.

What is the typical MOQ and pricing range?

Minimum order quantities vary: automated production lines often require 1 set (priced $25,000–$1.5M), while electronic assemblies may start at 1–10 pieces ($0.20–$200/unit). Pricing depends on complexity, materials, and level of integration.

Do suppliers support full customization?

Yes, most offer configurable options including material type, color, dimensions, branding (logo, labels), and functional parameters (voltage, control systems). Full turnkey design services are available from top-tier providers in Shenzhen and Dongguan.

What are standard lead times for custom assembly projects?

Lead times typically range from 30 to 60 days post-design approval. Prototypes for electronic boards can be delivered in 10–15 days, while complex machinery such as battery or motor assembly lines may require 8–12 weeks.

Can suppliers handle global shipping and compliance?

Most experienced exporters manage international logistics via FOB or CIF terms. However, buyers must confirm compatibility with destination-market standards (e.g., CE, UL, IEC) for electrical and mechanical systems prior to shipment.