Assembly Contracts

About assembly contracts

Where to Find Assembly Contracts Suppliers?

China remains the global epicenter for electronics and product assembly services, with Shenzhen and Dalian emerging as key hubs for contract manufacturing. These regions host vertically integrated supply chains that support rapid prototyping, low-to-high volume production, and end-to-end logistics. Shenzhen alone accounts for over 60% of China’s electronics contract manufacturers, leveraging proximity to component suppliers, automated SMT lines, and streamlined export channels through the Pearl River Delta.

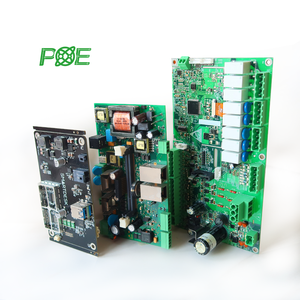

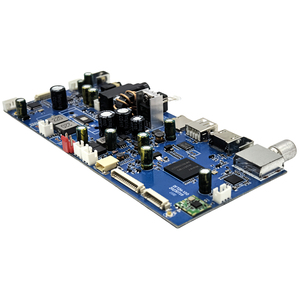

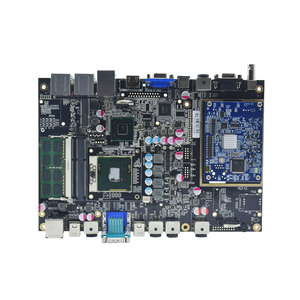

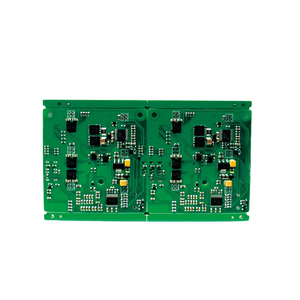

The industrial ecosystem enables suppliers to offer scalable solutions—from single-piece prototypes to mass production runs—while maintaining tight tolerances and compliance standards. Buyers benefit from localized sourcing of PCBs, ICs, and packaging materials, reducing material lead times by 20–35% compared to offshore alternatives. Typical advantages include MOQs as low as one unit, per-unit pricing starting below $0.10 for high-volume orders, and full customization across design, labeling, and packaging. Turnkey capabilities often encompass PCB design, BOM sourcing, SMT/DIP assembly, AOI inspection, and final product boxing.

How to Choose Assembly Contracts Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional parameters:

Technical & Production Capabilities

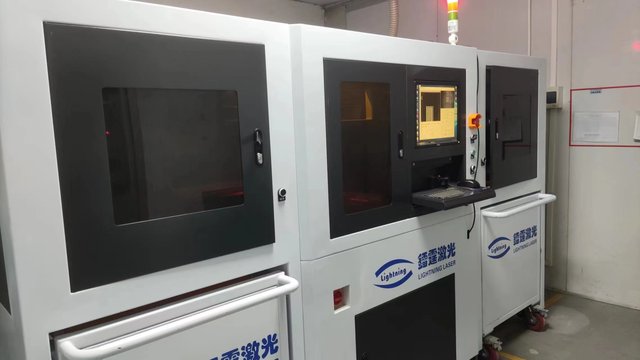

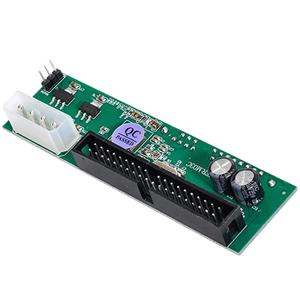

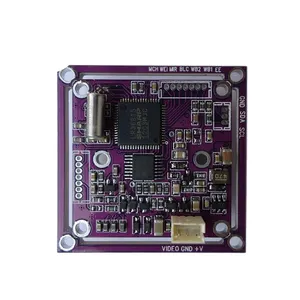

Verify access to surface mount technology (SMT) lines, automated optical inspection (AOI), and in-circuit testing (ICT). Preferred suppliers maintain in-house engineering teams capable of handling PCB reverse engineering, IC programming, and rigid-flex board assembly. Confirm compatibility with FR4, HDI, and FPC substrates, as well as support for micro-components down to 0201 package sizes.

Quality Assurance Protocols

Prioritize partners demonstrating adherence to IPC-A-610 Class 2/3 standards and ISO 9001-certified workflows. Request documentation for solder paste inspection (SPI), thermal profiling, and environmental stress testing. For medical or industrial applications, ensure compliance with RoHS, REACH, and UL marking requirements where applicable.

Operational Performance Metrics

Evaluate based on verified performance indicators:

- On-time delivery rate exceeding 98%

- Response time under 4 hours (ideal: ≤1 hour)

- Reorder rate above 30% indicating customer retention

- Minimum factory area supporting dedicated production cells

Cross-reference these metrics with service scope, particularly for turnkey versus partial assembly models.

Transaction Security & Scalability

Utilize secure payment frameworks with milestone-based disbursements tied to production phases. Assess financial stability through annual online revenue benchmarks—suppliers reporting US$300,000+ indicate established operations. Conduct video audits of assembly floors prior to full-scale engagement, focusing on workstation organization, ESD controls, and traceability systems.

What Are the Best Assembly Contracts Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|---|

| Shenzhen Topwell Innovations Co., Ltd. | Shenzhen, CN | Custom Product Assembly, PCB + Packing | Color, material, size, logo, packaging, label, graphic | 100% | 50% | ≤4h | US $710,000+ | 1–50 sets | $0.18–0.50 |

| Shenzhen Yongkefeng Technology Co., Ltd. | Shenzhen, CN | PCBA, Multilayer PCB, OEM Modules | PCBA (327 listings), FPC, ODM designs | 100% | 25% | ≤1h | US $70,000+ | 1 piece | $2.20–222 |

| Tecoo Electronics Co., Ltd. | Shenzhen, CN | Full Turnkey PCBA, SMT, ODM | Precision assembly, BOM sourcing, AOI, cloning, IC programming | 98% | 32% | ≤3h | US $460,000+ | 10 pieces | $0.50–10 |

| Dalian Jy Electronics & Technology Co., Ltd. | Dalian, CN | PCB Assembly, Cable Burning, Box Building | Boxes, cables, color, logo, packaging, label | 100% | 41% | ≤1h | US $300,000+ | 1 piece | $0.10–1.00 |

| Shenzhen Yachuanglian Technology CO.,Ltd. | Shenzhen, CN | OEM/ODM PCBA, Medical Device Assembly | Color, material, size, logo, packaging, label | 100% | 28% | ≤2h | US $270,000+ | 1 piece | $0.88–5.00 |

Performance Analysis

Shenzhen-based suppliers dominate in service breadth and customization depth, with Tecoo Electronics offering comprehensive engineering support including reverse engineering and automated inspection. Dalian Jy Electronics stands out for ultra-low-cost assembly ($0.10/unit minimum) and rapid response cycles, ideal for cost-sensitive prototyping. Shenzhen Topwell leads in customer retention (50% reorder rate), signaling strong satisfaction in packaging integration and color/material flexibility. While Yongkefeng and Yachuanglian report faster average response times (≤1h and ≤2h respectively), their lower reorder rates suggest room for improvement in post-sale execution. All top-tier suppliers guarantee 100% on-time delivery, underscoring reliable scheduling control—critical for Just-in-Time inventory models.

FAQs

How to verify assembly contract supplier reliability?

Request documented evidence of quality management systems (e.g., ISO 9001), sample production reports with AOI/SPI data, and client references in similar product categories. Validate component sourcing policies, especially for avoiding counterfeit ICs through authorized distributors.

What is the typical lead time for assembly contracts?

Standard turnaround ranges from 5–15 days for prototype batches (1–100 units), extending to 20–30 days for full turnkey orders involving BOM procurement. Expedited services are available at premium rates, with some suppliers offering 72-hour assembly for pre-stocked components.

Do suppliers support small batch or single-unit orders?

Yes, all listed suppliers accept minimum orders of 1 piece, making them suitable for R&D, pilot testing, and niche market launches. Unit costs decrease significantly at volumes exceeding 1,000 pieces due to setup amortization.

Can I customize packaging and branding?

Full branding customization—including private labeling, custom box dimensions, user manuals, and graphic design—is standard among leading providers. Digital proofing is typically provided within 24–48 hours before production launch.

Are there additional costs beyond unit pricing?

Potential add-ons include stencil fees (~$50), programming charges for new PCB designs (~$100–300), and tooling for specialized test fixtures. These are often waived for recurring orders or annual contracts exceeding 10,000 units.