Assembly Line Robotics

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About assembly line robotics

Where to Find Assembly Line Robotics Suppliers?

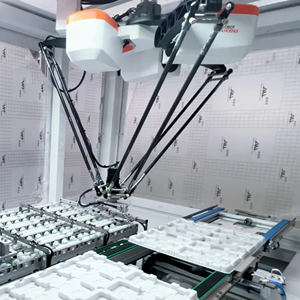

China remains a central hub for assembly line robotics manufacturing, with key production clusters in Guangdong and Shanghai offering specialized expertise. Shenzhen and Guangzhou in Guangdong province host advanced robotics developers focused on precision automation, leveraging proximity to electronics and machinery supply chains. These regions support rapid prototyping and integration of robotic arms, SCARA systems, and parallel robots used in high-speed manufacturing environments.

The industrial ecosystem enables vertically integrated production, where component sourcing, R&D, and final assembly occur within compact geographic zones. This structure reduces lead times—typically 30–45 days for standard robotic units—and supports cost efficiencies through localized machining, electronics procurement, and software calibration. Buyers benefit from scalable output, with suppliers capable of fulfilling both low-volume custom orders and bulk deployments across automotive, electronics, and packaging industries.

How to Choose Assembly Line Robotics Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer validated robotics solutions aligned with application needs—such as six-axis articulated robots for welding or Delta robots for high-speed sorting. Prioritize companies with documented experience in deployment scenarios matching payload, accuracy (±0.02mm typical), and cycle time requirements. Request performance data on repeatability, controller compatibility, and integration with PLCs or MES systems.

Production Infrastructure Assessment

Evaluate core manufacturing competencies:

- In-house design and engineering teams for customization

- CNC machining, welding, and control system assembly capabilities

- On-site testing facilities for motion calibration and endurance validation

Cross-reference facility size indicators and online revenue metrics with on-time delivery rates (target ≥95%) to assess reliability and scalability.

Quality and Transaction Assurance

While formal certifications (ISO 9001, CE) are not explicitly stated in available data, prioritize suppliers demonstrating consistent quality through reorder rates above 50% and response times under 3 hours. Use secure payment mechanisms and request pre-shipment inspection rights. Prototype testing is critical—validate robot performance using application-specific tasks before full-scale procurement.

What Are the Best Assembly Line Robotics Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Penghui Intelligent Manufacturing Electronics (Shenzhen) Co., Ltd. | Cable Manufacturing Equipment, Soldering & Gluing Machines | Not specified | Not specified | 100% | ≤1h | 26% | $80,000+ |

| Robotphoenix Intelligent Technology Co.,Ltd | SCARA Robots, Delta Robots, Industrial Manipulators | $5,000–$15,200 | 1 set | 100% | ≤2h | 100% | $30,000+ |

| Guangdong Borunte Robot Technology Co., Ltd. | 6-Axis Articulated Robots, Collaborative Units | $1,999–$18,800 | 1 set | 66% | ≤3h | 100% | $20,000+ |

| Guangzhou Sanhok Hitech Co., Ltd. | Custom Automated Assembly Lines, Sweeping Robot Production Systems | $8,000–$29,998 | 1–10 sets | 100% | ≤5h | 50% | $220,000+ |

| Shanghai Qiongkuo Intelligent Equipment Co., Ltd. | Robotic Welding Fixtures, Custom Clamps, Assembly Jigs | $6,000–$10,000 | 1 set | 100% | ≤8h | - | - |

Performance Analysis

Robotphoenix stands out with a 100% reorder rate and competitive pricing on SCARA and Delta robots, indicating strong customer satisfaction in high-speed automation applications. Penghui and Sanhok demonstrate flawless on-time delivery, with Sanhok leading in reported online revenue ($220,000+), suggesting robust export activity and capacity for large-scale system integration. Borunte offers the widest price range and lower entry costs ($1,999 units), though its 66% on-time delivery rate presents a risk for time-sensitive deployments. Shanghai Qiongkuo specializes in robotic tooling rather than full systems, serving as a strategic partner for fixture customization but requiring integration with primary robotic platforms.

FAQs

How to verify assembly line robotics supplier reliability?

Assess response consistency, order fulfillment history, and product-specific performance data. Request access to client references or case studies involving similar automation tasks. For critical applications, conduct virtual audits of production and testing processes to confirm engineering rigor.

What is the typical lead time for robotic systems?

Standard robotic arms or manipulators typically ship within 30–45 days after order confirmation. Customized automation lines may require 60–90 days depending on complexity. Prototypes can be delivered in 4–6 weeks for validation.

Can suppliers provide customized robotics solutions?

Yes, several suppliers offer configuration options for payload, reach, mounting style, and control interface. Guangzhou Sanhok and Shanghai Qiongkuo explicitly support customization in materials, branding, and mechanical design for integration into existing production environments.

What are common minimum order quantities?

Most suppliers list a minimum order of 1 set for robotic units, enabling low-volume trials. For peripheral equipment like conveyors or fixtures, MOQs may range up to 10 sets. Negotiation is feasible for pilot projects or long-term partnerships.

How are robotics systems tested before shipment?

Reputable suppliers perform functional tests including motion accuracy checks, cycle endurance runs, and safety protocol verification. Buyers should request test reports or video demonstrations of operational performance under simulated conditions prior to dispatch.