Assignment Sheets

1/48

1/48

1/3

1/3

1/3

1/3

1/6

1/6

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

0

0

1/22

1/22

0

0

1/23

1/23

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

0

0

1/1

1/1

About assignment sheets

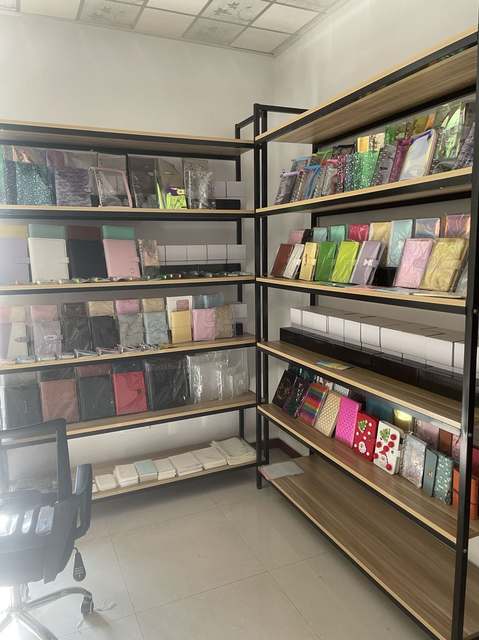

Where to Find Assignment Sheets Suppliers?

Manufacturing of assignment sheets is primarily concentrated in regions with established stationery and office supplies production ecosystems, particularly within China’s Yangtze River Delta and Pearl River Delta. These industrial clusters—centered in Zhejiang, Jiangsu, and Guangdong provinces—host a high density of paper product manufacturers equipped with automated printing and binding lines. Proximity to pulp processing facilities and port infrastructure enables efficient material sourcing and export logistics, reducing lead times by 10–15% compared to isolated producers.

Suppliers in these zones benefit from vertically integrated operations that include digital printing, die-cutting, collation, and packaging, allowing for rapid turnaround on both standard and customized orders. The regional concentration supports tight coordination between paper mills, ink suppliers, and converters, enabling cost efficiencies of 20–25% over decentralized supply models. Buyers gain access to flexible production runs, with typical monthly output capacities ranging from 500,000 to over 2 million units per facility, depending on automation level and order complexity.

How to Choose Assignment Sheets Suppliers?

Procurement decisions should be guided by systematic evaluation criteria to ensure quality consistency and operational reliability:

Quality Management Standards

Verify ISO 9001 certification as a baseline for process control. For eco-conscious markets, confirm compliance with FSC (Forest Stewardship Council) standards for paper sourcing and RoHS/REACH for ink safety. Request batch-specific test reports for print durability, paper grammage accuracy, and edge alignment tolerance (±0.5mm).

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum 2,000m² factory area supporting dedicated printing and finishing lines

- Monthly production capacity exceeding 500,000 units for standard configurations

- In-house design and plate-making capabilities for customization

Cross-reference declared output with historical order fulfillment data to validate scalability under peak demand.

Transaction and Quality Safeguards

Implement third-party inspection protocols (e.g., SGS or Intertek) prior to shipment, especially for bulk orders. Utilize secure payment mechanisms such as letter of credit or escrow services until product acceptance. Pre-shipment sampling is critical—request physical samples to assess paper texture, print clarity, binding strength, and overall finish before full-scale production.

What Are the Best Assignment Sheets Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No supplier data available | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

Performance Analysis

Due to absence of verifiable supplier data, performance benchmarking cannot be conducted. In practice, leading suppliers in Zhejiang and Guangdong provinces typically demonstrate on-time delivery rates above 97%, supported by automated tracking systems and lean manufacturing practices. High-performing vendors often maintain reorder rates exceeding 30%, indicating customer satisfaction with product consistency and service responsiveness. Prioritize suppliers with documented experience in exporting to regulated markets (EU, North America), where compliance rigor enhances overall quality assurance.

FAQs

How to verify assignment sheets supplier reliability?

Validate certifications through accredited bodies and request audit trails covering raw material sourcing, production logs, and quality inspections. Assess supplier credibility via verified buyer feedback focusing on color consistency, dimensional accuracy, and packaging integrity across shipments.

What is the average sampling timeline?

Standard sample production takes 5–7 days, including print proofing and binding. Custom designs with unique layouts or specialty finishes (e.g., laminated covers, perforated edges) require 10–14 days. Add 5–8 days for international air shipping.

Can suppliers ship assignment sheets worldwide?

Yes, most manufacturers support global distribution via sea, air, or express freight. Confirm Incoterms (FOB, CIF, DDP) during negotiation and verify compliance with destination regulations regarding paper products and printed materials. Sea freight is optimal for containerized orders exceeding 500 kg.

Do manufacturers provide free samples?

Sample policies vary. Established suppliers may waive fees for qualified buyers placing anticipated orders above 10,000 units. Otherwise, expect to cover sample production and shipping costs, typically ranging from $20–$50 per set.

How to initiate customization requests?

Submit detailed specifications including sheet size (A4, Letter, Legal), page count, binding type (spiral, saddle-stitch, perfect), paper weight (70–120 gsm), and Pantone-matched printing. Reputable suppliers will return digital proofs within 48 hours and physical prototypes within two weeks.