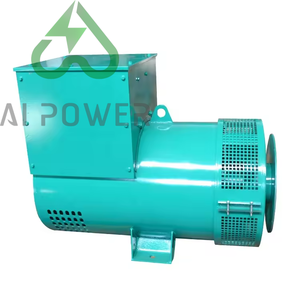

Asynchronous Generator Producer

1/8

1/8

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/15

1/15

1/3

1/3

CN

CN

1/27

1/27

1/3

1/3

CN

CN

1/19

1/19

1/29

1/29

1/3

1/3

1/3

1/3

1/3

1/3

1/21

1/21

1/3

1/3

0

0

About asynchronous generator producer

Where to Find Asynchronous Generator Producers?

China remains the central hub for asynchronous generator manufacturing, with key production clusters in Jiangsu, Zhejiang, and Hebei provinces. These regions host vertically integrated industrial ecosystems that support efficient electromechanical component sourcing, precision machining, and final assembly. Jiangsu’s Changzhou and Wuxi zones are particularly notable, housing over 45% of China’s industrial motor and generator producers due to proximity to rare earth material processors and copper refineries.

The concentration enables streamlined production cycles, with localized access to stator windings, cast iron frames, aluminum die-cast rotors, and insulated coil materials within 50km supply radii. This integration supports MOQs as low as 10 units for custom configurations while maintaining scalability for bulk orders exceeding 500 units per month. Lead times average 35–50 days for standard three-phase induction generators (ranging from 5kW to 10MW), with export-ready packaging and IEC 60034 compliance commonly available. Cost advantages stem from reduced material logistics—up to 18% lower component procurement costs compared to EU-based manufacturers—and mature workforce specialization in electromagnetic design and thermal testing protocols.

How to Choose Asynchronous Generator Producers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and supply chain resilience:

Quality Management Verification

Confirm ISO 9001 certification as a baseline for documented quality control systems. For international deployment, validate compliance with IEC 60034-1 (efficiency classes IE2/IE3), CE marking for EU market access, and RoHS conformity where applicable. Request test reports on no-load current, insulation resistance (minimum 100 MΩ at 500V DC), and temperature rise under continuous duty (Class B/F insulation limits).

Production Infrastructure Assessment

Evaluate core operational capabilities through objective benchmarks:

- Minimum factory footprint of 3,000m² to support dedicated winding, balancing, and dynamometer testing lines

- In-house rotor casting and stator varnishing processes to control critical tolerances

- Engineering team comprising ≥8% of total staff to support OEM designs and efficiency optimization

Correlate facility scale with order fulfillment performance—target suppliers with demonstrated on-time delivery rates above 97%.

Transaction and Technical Safeguards

Utilize secure payment structures such as letter of credit or escrow arrangements until site acceptance testing is completed. Require sample validation against specified parameters including slip rate (typically 2–6%), power factor (≥0.85 at full load), and noise levels (≤75 dB(A) at 1m). Insist on prototype delivery within 4 weeks for non-standard frame sizes or dual-speed configurations.

What Are the Key Considerations When Sourcing Asynchronous Generators?

While specific supplier data is currently unavailable, industry benchmarks provide actionable guidance for buyer decision-making:

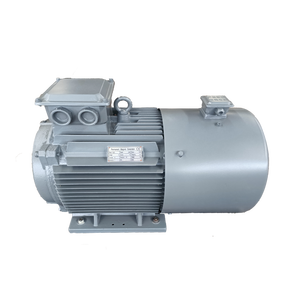

Performance and Customization Parameters

Standard asynchronous generators are typically built to IP55 ingress protection, with options for IP56 in high-humidity environments. Common mounting configurations include B3 (foot-mounted), B5 (flange-mounted), and B35 (combined). Voltage adaptability spans 220V–690V AC, with frequency tolerance for both 50Hz and 60Hz grids. Buyers seeking regenerative braking or variable-speed operation must confirm compatibility with external VFD control systems.

Customization lead time increases by 10–20 days for modified cooling fans, special bearings (e.g., SKF seals), or marine-grade corrosion protection. High-efficiency models using cold-rolled silicon steel laminations can achieve IE3 ratings but may carry a 12–15% premium over IE2 equivalents.

Logistics and Export Readiness

Most established producers offer FOB terms from Shanghai, Ningbo, or Qingdao ports, with container loading optimized for 20ft or 40ft HC units. Generators above 2 tons require skid-mounted frames for forklift handling and shock-absorbing crating. Ensure suppliers provide comprehensive documentation packages including wiring diagrams, alignment specifications, and commissioning checklists for customs clearance and installation support.

FAQs

How to verify asynchronous generator producer credibility?

Audit issued certifications through official registries and request factory inspection reports from third-party agencies. Review historical shipment records and assess after-sales service capacity, particularly technical support availability in local time zones.

What is the typical sampling timeline for asynchronous generators?

Standard samples take 20–30 days to produce, depending on stock availability of core components. Custom prototypes involving new tooling or insulation systems may require 45 days. Air freight adds 5–8 days for global delivery.

Can asynchronous generator producers handle global exports?

Yes, experienced manufacturers manage international logistics and comply with destination-specific regulations, including EPA standards for associated prime movers and grid synchronization requirements. Confirm Incoterm clarity—FOB, CIF, or DDP—to allocate risk appropriately.

Do suppliers offer free samples?

Free samples are uncommon due to high unit value. Suppliers typically charge 30–60% of list price for evaluation units, refundable upon placement of volume orders (usually 10+ units).

How to initiate technical customization?

Submit detailed specifications covering rated power, shaft dimensions, insulation class, ambient operating temperature, and required duty cycle. Leading producers respond with engineering proposals, 3D mounting drawings, and test plans within 5 business days.