Atlas Robots

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

1/33

1/33

1/3

1/3

0

0

1/14

1/14

1/3

1/3

1/3

1/3

1/3

1/3

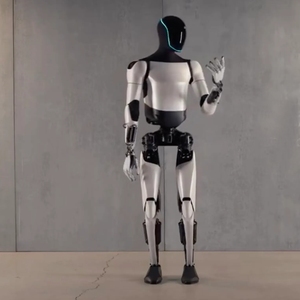

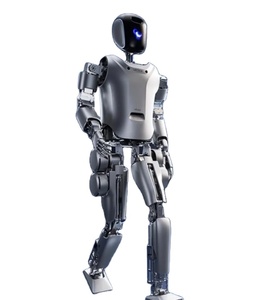

About atlas robots

Where to Source Atlas Robots Suppliers?

China leads global production of humanoid and industrial robotics, with key manufacturing hubs in Guangdong, Fujian, and Jiangsu provinces. These regions host vertically integrated supply chains combining precision engineering, AI integration, and automated assembly lines. Guangzhou and Shenzhen serve as innovation centers for commercial service robots, leveraging proximity to semiconductor and sensor suppliers that reduce component lead times by 25–40%. Fuzhou and Wuxi facilities specialize in mid-volume production runs, offering flexible configurations for delivery, reception, and intelligent walking platforms.

The concentration of R&D talent and Tier-1 automation partners enables rapid prototyping and scalable manufacturing. Buyers benefit from ecosystems where motor control systems, LIDAR modules, and battery packs are sourced within 50km, supporting faster iteration cycles. Average production lead times range from 30–60 days depending on customization level, with standard models available for immediate dispatch. Cost advantages stem from localized procurement—reducing unit prices by 18–30% compared to non-Asian manufacturers—while maintaining compatibility with international safety and performance benchmarks.

How to Evaluate Atlas Robots Suppliers?

Implement structured assessment protocols to ensure technical and operational reliability:

Technical Validation

Confirm compliance with relevant standards including ISO 9001 for quality management and CE marking for electrical safety. For autonomous navigation systems, verify functional testing documentation covering obstacle avoidance, path planning accuracy, and voice interaction latency. Request firmware version logs and software update policies to assess long-term supportability.

Production Capacity Assessment

Analyze infrastructure indicators:

- Minimum factory area exceeding 2,000m² for stable output

- In-house capabilities in CNC machining, PCB assembly, and final system integration

- Dedicated QA stations with cycle testing for motor endurance and battery life

Correlate on-time delivery rates (target ≥95%) with reorder metrics to validate scalability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services until acceptance testing is completed. Prioritize suppliers with documented dispute resolution histories and clear warranty terms (minimum 12 months on core components). Conduct pre-shipment inspections via third-party auditors or remote video verification, focusing on motion stability, sensor calibration, and UI responsiveness.

What Are the Top Atlas Robots Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Value |

|---|---|---|---|---|---|---|

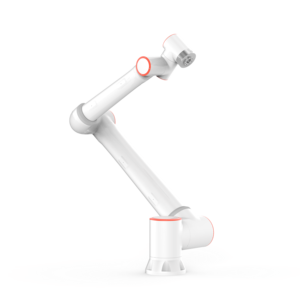

| Ounaian Electronic Technology (Fuzhou) Co., Ltd. | Articulated Robots, Collaborative Robots, Optical Sensors | US $7,000+ | 50% | 66% | ≤2h | $20,000+ |

| AVOS AUTO EXPORTS LIMITED | Humanoid Robots, Bio-Inspired Robotics | - | - | - | ≤6h | $9,000+ |

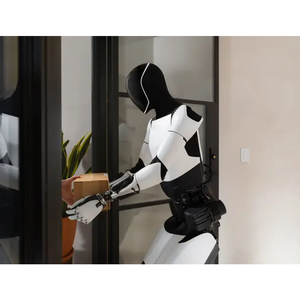

| Guangzhou Robin Intelligent Robot Co., Ltd. | Commercial Delivery Robots, Reception Robots | US $40,000+ | 100% | <15% | ≤1h | $3,999+ |

| Wuxi Benefit Technology Co., Ltd. | Humanoid Service Robots, Advertising Robots | US $10,000+ | 100% | 20% | ≤1h | $3,199+ |

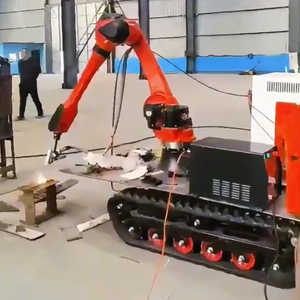

| Shenzhen Era Automation Co., Ltd. | Industrial Cobot Arms, AGVs | US $380,000+ | 100% | 25% | ≤2h | $3,600+ |

Performance Analysis

Shenzhen Era Automation demonstrates strong industrial-grade output with high online revenue and perfect on-time fulfillment, positioning it as a preferred partner for robotic arms and automation cells. Guangzhou Robin and Wuxi Benefit achieve 100% on-time delivery with sub-2-hour response times, indicating robust order management despite lower reorder rates. Ounaian Electronic shows a high reorder rate (66%), suggesting niche market alignment, though its 50% delivery performance indicates potential logistical constraints. AVOS AUTO EXPORTS offers competitive entry-level pricing but lacks verifiable transaction data, increasing procurement risk. Buyers seeking volume deployments should prioritize suppliers with proven after-sales infrastructure and firmware update support.

FAQs

How to verify atlas robots supplier credibility?

Cross-check declared certifications with official registries. Request evidence of past shipments through bill of lading samples or export declarations. Assess technical competence via live demos or recorded operation tests under real-world conditions.

What is the typical MOQ and pricing range?

Standard MOQ is 1 unit across all major suppliers, enabling pilot testing. Unit prices vary significantly by function: commercial delivery robots start at $3,999, while advanced humanoid models exceed $25,000. Bulk orders (5+ units) typically qualify for 5–12% discounts.

Can suppliers customize robot functionality?

Yes, most manufacturers support hardware and software modifications. Common customizations include voice command localization, payload adjustments, API integration for enterprise systems, and exterior branding. Development timelines range from 2–6 weeks depending on complexity.

Do suppliers provide technical documentation?

Reputable vendors supply user manuals, maintenance guides, SDKs, and wiring diagrams. Confirm availability of English-language materials and API access prior to purchase. Some require NDA agreements before releasing full technical packages.

What are the shipping and import considerations?

Robots are typically shipped via air freight (DAP or FOB terms) due to weight and sensitivity. Import classifications depend on function—service robots may fall under HS code 8479.89, subject to tariffs varying by destination. Ensure compliance with local electrical safety and radio frequency regulations, especially for Wi-Fi/Bluetooth-enabled models.