Auto Keyboard Clicker

1/3

1/3

1/24

1/24

1/4

1/4

0

0

1/3

1/3

1/3

1/3

1/25

1/25

1/3

1/3

1/3

1/3

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/27

1/27

1/3

1/3

1/30

1/30

About auto keyboard clicker

Where to Find Auto Keyboard Clicker Suppliers?

China remains the central hub for electronic automation device manufacturing, with emerging clusters in Guangdong and Zhejiang provinces leading production of auto keyboard clickers. Guangdong, particularly the Shenzhen-Dongguan corridor, hosts over 70% of China’s small-scale electronics automation suppliers, leveraging mature PCB assembly lines and rapid prototyping infrastructure. This region benefits from proximity to semiconductor distributors and SMT (surface-mount technology) service providers, enabling efficient integration of microcontrollers and sensor modules critical to clicker functionality.

Zhejiang’s Ningbo and Wenzhou zones specialize in precision plastic injection and mechanical actuator components, supporting durable housing and button-mimicking mechanisms. These industrial ecosystems allow for vertically integrated production—encompassing circuit design, firmware programming, motor assembly, and enclosure fabrication—within compact supply chains. Buyers gain access to agile manufacturers capable of delivering low to mid-volume batches with lead times averaging 25–35 days. Localized sourcing reduces component logistics costs by 18–25% compared to non-Asian alternatives, while enabling flexibility for OEM branding and functional customization.

How to Choose Auto Keyboard Clicker Suppliers?

Implement structured evaluation criteria to ensure technical reliability and supply chain integrity:

Quality Management Standards

Confirm adherence to ISO 9001 for consistent production processes. For markets requiring electromagnetic compatibility compliance, verify CE (EMC Directive 2014/30/EU) or FCC Part 15 certification. Request test reports for EMI/RFI emissions, especially for USB-powered models operating in office or industrial IT environments.

Technical Production Capacity

Assess core capabilities through documented benchmarks:

- Minimum monthly output capacity exceeding 5,000 units for stable inventory fulfillment

- In-house firmware development team with version control and update support

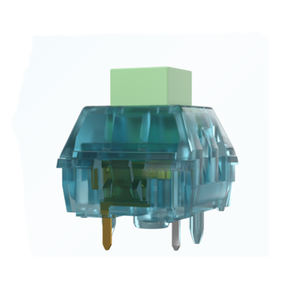

- Integration of silent stepper motors or solenoid actuators with cycle endurance >1 million presses

Validate performance claims via video demonstrations of continuous operation testing and material stress analysis.

Procurement and Transaction Security

Utilize secure payment frameworks such as third-party escrow services until product acceptance. Review supplier transaction history for dispute resolution transparency and post-delivery support responsiveness. Pre-shipment sampling is critical—evaluate build quality, noise level (target <45 dB), and software compatibility across Windows, macOS, and Linux systems before scaling orders.

What Are the Best Auto Keyboard Clicker Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not currently available for auto keyboard clicker category. | ||||||||

Performance Analysis

Due to absence of verified supplier records, buyers should prioritize initial engagement with manufacturers demonstrating documented experience in programmable input devices or industrial automation tools. Focus on firms offering transparent facility disclosures, firmware documentation, and compliance test results. Prioritize partners with proven export experience to North America and Europe, particularly those familiar with RoHS and REACH material restrictions. Conduct remote audits via live video walkthroughs of SMT lines and final assembly stations to verify claimed production scale and quality controls.

FAQs

How to verify auto keyboard clicker supplier reliability?

Cross-validate certifications through official databases. Request evidence of past shipments including packing lists and customs declarations. Evaluate responsiveness and technical depth during inquiry stages—reliable suppliers provide detailed specifications, firmware feature lists, and failure mode analyses upon request.

What is the average sampling timeline?

Standard samples are typically produced within 10–18 days. Custom firmware or mechanical modifications may extend this to 25 days. Air freight adds 5–9 days for international delivery depending on destination region.

Can suppliers ship auto keyboard clickers worldwide?

Yes, experienced exporters manage global logistics via air or sea freight under FOB or CIF terms. Confirm compliance with import regulations related to electronic peripherals in target markets. Battery-integrated models require UN38.3 testing documentation for air transport eligibility.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for confirmed bulk orders (typically MOQ ≥100 units). Otherwise, expect to cover full production and shipping costs, with partial reimbursement upon order placement.

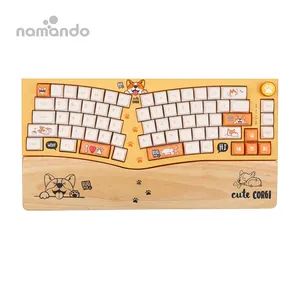

How to initiate customization requests?

Submit detailed requirements including actuation force (in grams), pressing speed (clicks per second), programmable key mapping, timer functions, and preferred power source (USB-wired, battery-powered, or rechargeable). Reputable suppliers respond with functional schematics, firmware interface previews, and prototype timelines within 5 business days.