Automated Conveyor System

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/11

1/11

1/2

1/2

0

0

0

0

1/3

1/3

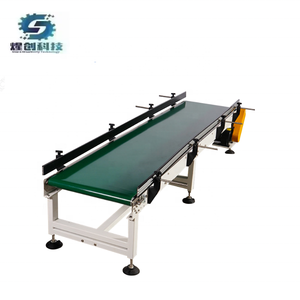

About automated conveyor system

Where to Find Automated Conveyor System Suppliers?

China remains the global hub for automated conveyor system manufacturing, with key industrial clusters in Jiangsu, Shandong, and Guangdong provinces offering scalable production and specialized engineering. Suzhou and Qingdao host advanced material handling ecosystems, integrating R&D centers, precision fabrication facilities, and export logistics networks. These regions benefit from concentrated supply chains for motors, drive systems, and structural components, enabling cost reductions of 20–35% compared to Western manufacturers.

The clusters support both standardized and engineered-to-order systems through vertically integrated operations—spanning sheet metal processing, control panel assembly, and system integration. Buyers access rapid prototyping (7–14 days), modular designs for easy expansion, and compliance-ready configurations. Typical advantages include lead times of 25–40 days for custom builds, MOQs as low as 1 meter or set, and scalability for high-volume deployments across warehousing, food processing, and logistics sectors.

How to Choose Automated Conveyor System Suppliers?

Implement structured evaluation criteria to ensure technical reliability and supply chain resilience:

Technical Compliance & Certifications

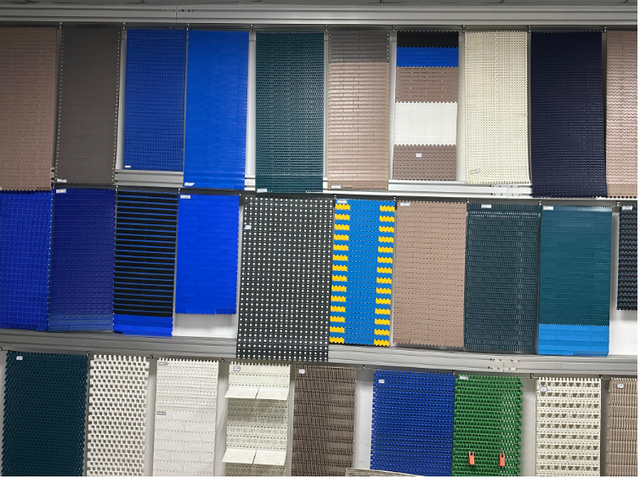

Confirm adherence to international standards such as ISO 9001 for quality management. For EU and North American markets, verify CE marking and electrical safety compliance (e.g., IEC 60204). Request documentation on motor efficiency ratings, belt material certifications (FDA for food-grade, UL for fire resistance), and control system compatibility (PLC brands, IoT readiness).

Production Capability Assessment

Evaluate core manufacturing infrastructure:

- Minimum 5,000m² factory area for large-scale assembly

- In-house capabilities in CNC cutting, welding, and electrical integration

- Dedicated design teams supporting CAD layout planning and dynamic simulation

Cross-check online revenue indicators (>US $100,000+) and reorder rates (>25%) as proxies for market validation and post-sales performance.

Customization & Integration Readiness

Prioritize suppliers offering configurable parameters: belt type (PVC, PU, stainless steel), frame material (aluminum, carbon steel), motor power (AC/DC, variable speed), and integration with sorting, scanning, or warehouse management systems. Confirm availability of 3D layout drawings, load capacity testing data, and compatibility with existing automation platforms.

Transaction Security Protocols

Utilize secure payment methods with milestone-based releases. Require product-specific test reports—including no-load operation trials and dimensional verification—before shipment. Leverage inspection services at origin or destination to validate functionality, especially for complex multi-zone conveyors.

What Are the Best Automated Conveyor System Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Xinlilong Intelligent Equipment (Suzhou) Co., Ltd. | Conveyors (284) | US $50,000+ | 100% | ≤2h | 22% | Layout, motor, color, size, belt design | 1 meter |

| Shandong Chenming Intelligent Equipment Co., Ltd. | Conveyors (871) | US $100,000+ | 100% | ≤1h | 25% | Material, chain type, configuration | 10 meters / 1 set |

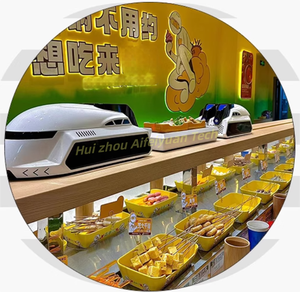

| Huizhou Aifeiyuan Technology Co., Ltd. | Conveyors (N/A) | US $470,000+ | 100% | ≤1h | 30% | Size, motor, color, frame, rainproofing | 10 meters |

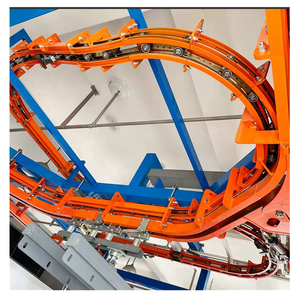

| Chongqing Haodong Technology Co., Ltd. | Conveyors (121) | US $140,000+ | 96% | ≤2h | 19% | Limited (standard overhead systems) | 50–100 meters |

| Shenzhen Weipai Tengda Technology Co., Ltd. | Conveyors (N/A) | US $330,000+ | 100% | ≤3h | 38% | Belt type, length, motor, sorting logic, graphics | 1 piece/set |

Performance Analysis

Shenzhen Weipai Tengda leads in customer retention (38% reorder rate), indicating strong satisfaction with its parcel sorting and cross-belt systems. Huizhou Aifeiyuan excels in niche food-service automation, particularly sushi conveyor lines with aesthetic customization. Shandong Chenming offers the broadest product range (871 listings), suggesting robust production capacity and component standardization. Xinlilong provides entry-level flexibility with 1-meter MOQs ideal for pilot installations. Chongqing Haodong specializes in low-cost overhead trolley systems but requires higher minimum orders, limiting suitability for small-scale buyers.

FAQs

How to verify automated conveyor system supplier reliability?

Audit supplier credentials by confirming ISO certification status and reviewing transaction history metrics—on-time delivery (>97%), response time (<2 hours), and reorder rate (>25%). Request references or case studies involving similar throughput requirements. Validate design capability through sample layout submissions and motor specification sheets.

What is the typical lead time for custom conveyor systems?

Standard configurations ship in 15–25 days. Customized systems with integrated controls or non-standard dimensions require 25–40 days, including design approval and pre-shipment testing. Expedited builds may reduce timelines by 5–7 days at additional cost.

Can suppliers integrate conveyors with existing warehouse automation?

Yes, leading suppliers support PLC-based interfacing (Siemens, Mitsubishi, Omron) and communication protocols (Modbus, Ethernet/IP). Confirm I/O compatibility and provide existing control architecture details prior to order finalization. Some vendors offer SCADA integration and remote monitoring upgrades.

Do manufacturers offer free samples or trial units?

Sample policies vary. Functional segment samples (1–2 meter sections) are sometimes provided at reduced cost for evaluation. Full-system trials are typically reserved for qualified bulk orders (≥50 meters or full-line deployment). Expect to cover shipping and handling fees in all cases.

How to initiate a customization request?

Submit detailed specifications including: required throughput (units/hour), load weight, environmental conditions (wet/dry, indoor/outdoor), curve radius, incline angle, and integration points. Reputable suppliers respond with CAD layouts, material options, and control schematics within 72 hours.