Automated Machines In Factories

Top sponsor listing

Top sponsor listing

CN

CN

About automated machines in factories

Where to Find Automated Machines in Factories Suppliers?

China remains the global epicenter for automated factory machinery manufacturing, with key industrial hubs in Shandong, Henan, and Guangdong provinces driving innovation and scale. Shandong is home to specialized food processing automation clusters, leveraging local expertise in mechanical design and integration. Henan has emerged as a center for chemical and soap production line automation, supported by robust supply chains for stainless steel and control systems. Guangdong’s Pearl River Delta region excels in liquid filling and packaging automation, benefiting from proximity to electronics and sensor component suppliers.

These regional ecosystems enable vertically integrated production—from CNC machining and sheet metal fabrication to PLC programming and final assembly—reducing lead times and improving cost efficiency. Buyers benefit from concentrated networks where engineering talent, component vendors, and logistics providers operate within tight geographic proximity. Typical advantages include 20–35% lower unit costs compared to Western manufacturers, lead times of 30–60 days for standard configurations, and strong flexibility for OEM/ODM customization.

How to Choose Automated Machines in Factories Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical and Functional Compliance

Verify that equipment meets applicable safety and performance standards such as CE or ISO 9001. For food-grade automation, ensure compliance with hygiene regulations including material certifications (e.g., SUS304 stainless steel) and design features like easy-clean surfaces and IP-rated electrical enclosures. Request documentation on motor specifications, control systems (PLC brands), and energy consumption metrics.

Production and Customization Capacity

Assess core capabilities through objective indicators:

- Confirmed ownership of in-house production lines (not trading-only operations)

- Proven experience in system integration for end-to-end assembly lines

- Offering of modular designs allowing capacity scaling (e.g., output adjustment from 2,000 to 20,000 units/hour)

- Support for customization in dimensions, power sources, feeding mechanisms, and packaging interfaces

Cross-reference product listings with response time and reorder rate data to gauge service reliability and post-sale satisfaction.

Transaction and Risk Mitigation Protocols

Prioritize suppliers offering verifiable quality assurance processes and secure payment terms. Use third-party inspection services prior to shipment to validate machine functionality and build quality. Analyze historical performance metrics such as on-time delivery rates (>95% recommended) and customer reorder frequency. Pre-shipment testing, including video run-offs or factory acceptance tests (FAT), should be standard practice for high-value orders.

What Are the Best Automated Machines in Factories Suppliers?

| Company Name | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Notable Product Lines |

|---|---|---|---|---|---|---|---|

| Zhucheng Lijie Food Machinery Co., Ltd. | Other Snack Machines (197); Food Processing Lines (196) | Blanching, slicing, frying, cooling, deoiling, labeling, nitrogen gas packaging, flouring, material size, logo style | 88% | <15% | ≤2h | US $240,000+ | Potato chips making machines, multi-stage snack processing lines |

| Jinan Mingde Machinery Co., Ltd. | Pet Food Processing Machines (560); Food Processing Lines (319) | Fried instant noodle production with capacity tuning and layout adaptation | - | 100% | ≤2h | - | Full-automatic Indomie and pet food production lines |

| Henan Taion Industry Co., Ltd. | Soap Making Machines (175); Multi-Function Packaging (29) | Toilet bar soap molding, wrapping, and full-line integration | 100% | <15% | ≤1h | US $10,000+ | Automatic laundry soap and toilet soap production lines |

| Guangzhou Guanhe Light Industry Machinery Co., Ltd. | Filling Machines (368); Capping & Sealing Systems (19) | Liquid viscosity adaptation, container size variation (200–750ml), BPH output scaling | 100% | 100% | ≤4h | US $5,000+ | High-viscosity sauce, vinegar, and barrel filling lines |

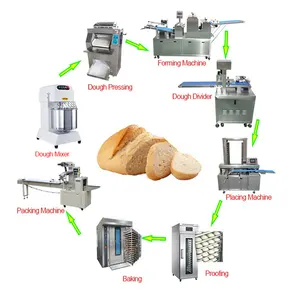

| Guangzhou Fuya Machinery Co., Ltd. | Food Processing Lines (148); Baking Ovens (59) | Maamoul biscuit shaping, tunnel oven heating type (gas/electric), line length customization | 100% | - | ≤4h | - | Automatic Maamoul and bread baking production systems |

Performance Analysis

Suppliers like Guangzhou Guanhe and Henan Taion demonstrate strong reliability with 100% on-time delivery and full customization support in niche segments such as liquid filling and soap manufacturing. Jinan Mingde stands out for customer retention (100% reorder rate), indicating high satisfaction despite limited public revenue data. Zhucheng Lijie offers broad configurability across food processing parameters but shows a lower reorder rate, suggesting potential gaps in after-sales service or consistency. Response times are generally fast, with 80% of these suppliers replying within 2 hours, enhancing communication efficiency for international buyers. For mission-critical deployments, prioritize partners with documented process validation and scalable factory infrastructure.

FAQs

How to verify automated machine supplier credibility?

Request evidence of owned production facilities via video tours or audit reports. Validate compliance claims (CE, ISO) through official databases. Review transaction history, focusing on consistent delivery performance and resolution of disputes. Third-party inspections pre-shipment are strongly advised for first-time partnerships.

What is the typical lead time for automated production lines?

Standard configurations require 30–45 days for manufacturing and testing. Customized systems may take 50–70 days depending on complexity. Add 10–20 days for international shipping via sea freight. Air freight options are limited due to size and weight constraints.

Do suppliers support OEM/ODM for factory automation systems?

Yes, most leading suppliers offer OEM branding and ODM engineering services. Clients can specify machine dimensions, throughput rates, control panel language, and integration with existing ERP/MES systems. Prototype development typically takes 3–5 weeks after specification finalization.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set for complete lines. Pricing varies widely: small-scale soap or snack lines start at $3,000–$8,500, while fully automated food or liquid filling systems range from $30,000 to $40,000. Volume discounts apply for multiple line installations.

Can automated machines be adapted for different raw materials?

Yes, many systems are designed for material flexibility. For example, food processors can handle various dough types or vegetable inputs with tooling changes. Confirm compatibility with your specific feedstock during technical consultations, including adjustments to cutting blades, conveyors, or heating elements.