Automated Sorting System Manufacturer

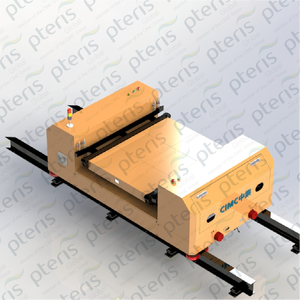

1/15

1/15

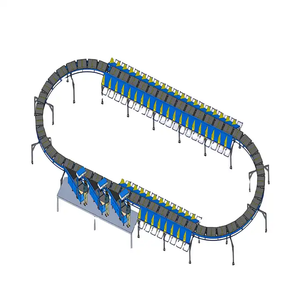

1/25

1/25

CN

CN

CN

CN

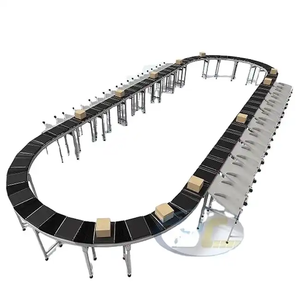

1/21

1/21

CN

CN

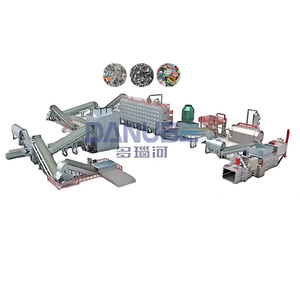

1/33

1/33

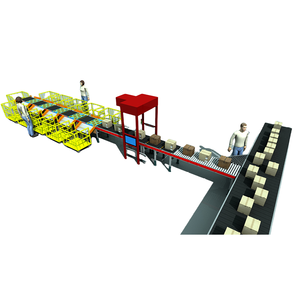

About automated sorting system manufacturer

Where to Find Automated Sorting System Manufacturers?

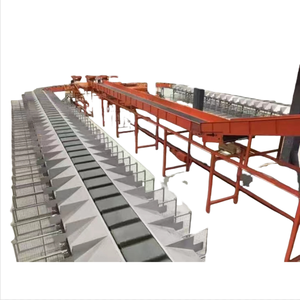

China remains the global epicenter for automated sorting system manufacturing, with key industrial hubs concentrated in Shanghai, Zhejiang, Guangdong, and Shenzhen. These regions host vertically integrated production ecosystems that combine advanced robotics, conveyor engineering, and intelligent logistics software. The proximity of component suppliers—ranging from servo motors to barcode scanning modules—enables rapid prototyping and scalable deployment. Suppliers in these clusters benefit from mature supply chains, reducing material lead times by 20–30% compared to non-specialized regions.

The sector is characterized by high operational efficiency, with many manufacturers operating under ISO-certified quality management systems and offering end-to-end automation solutions. Average factory areas exceed 5,000m², supporting dedicated R&D units focused on AI-driven sorting algorithms, cross-belt conveyor design, and DWS (Dimensioning, Weighing, Scanning) integration. Buyers gain access to flexible production models capable of fulfilling both standard configurations and fully customized systems tailored to parcel logistics, e-commerce fulfillment centers, or agricultural grading applications.

How to Choose Automated Sorting System Manufacturers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For export-bound systems, ensure compatibility with regional voltage requirements (e.g., 220V/380V) and control interfaces (PLC-based HMI panels). Request documentation on motor efficiency ratings, belt tensile strength, and sensor accuracy (e.g., barcode reading speed, volumetric measurement precision).

Production Infrastructure Audit

Assess core manufacturing competencies through verifiable metrics:

- Minimum factory footprint of 3,000m² to support assembly line operations

- In-house engineering teams specializing in automation controls and mechanical design

- Integrated testing protocols for system throughput (units/hour), error rate (<1%), and mean time between failures (MTBF)

- Cross-reference delivery performance (target ≥97%) with response times (ideally ≤5 hours) to gauge service responsiveness

Customization and Transaction Security

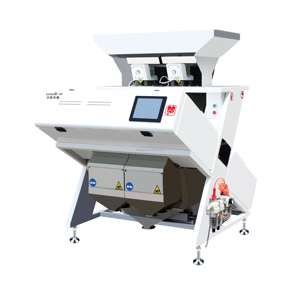

Prioritize suppliers offering modular designs and configurable parameters such as lane count, sorting direction, and integration with warehouse management systems (WMS). Confirm customization scope—including code, color, weight, volume, and shape detection—before procurement. Utilize secure payment mechanisms like escrow services and require pre-shipment inspection clauses. Sample validation is critical: benchmark system accuracy, noise levels (≤75 dB), and power consumption against project specifications prior to full-scale orders.

What Are the Leading Automated Sorting System Manufacturers?

| Company Name | Location | Verified Status | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (Min. Order) |

|---|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Shanghai, CN | Multispecialty Supplier | Automated parcel sorting, DWS systems, conveyor integration | 100% | ≤5h | 100% | US $60,000+ | $9,000–50,000/set |

| Zhejiang Xinli Electrical Equipment Co., Ltd. | Zhejiang, CN | - | Cross-belt sorters, high-speed logistics systems | 100% | ≤2h | - | US $6,000+ | $50,000/set |

| Guangdong Gosunm Intelligent Industry Co., Ltd. | Guangdong, CN | Custom Manufacturer | DWS systems, cross-belt sorters, intelligent conveying | 100% | ≤1h | 60% | US $210,000+ | $4,260–19,820/set |

| Linhai Linong Machinery Co., Ltd. | Zhejiang, CN | - | Fruit & vegetable grading machines | 100% | ≤5h | - | - | $10,000–100,000/piece |

| Huayuan (Shenzhen) Intelligent Equipment Co., Ltd. | Shenzhen, CN | - | Parcel sorting, DWS conveyors, narrow belt systems | 100% | ≤3h | 50% | US $330,000+ | $9,000–28,000/set |

Performance Analysis

Guangdong Gosunm and Huayuan (Shenzhen) demonstrate strong commercial traction, supported by high online revenue and proven reorder rates (60% and 50%, respectively), indicating customer satisfaction and repeat business. Senad Robot stands out with a perfect 100% reorder rate, reflecting exceptional service consistency. Zhejiang Xinli and Linhai Linong specialize in niche segments—industrial logistics and agricultural sorting—offering targeted expertise but limited reorder visibility. Response efficiency varies significantly: Guangdong Gosunm leads with sub-one-hour average replies, while others maintain acceptable turnaround within 5 hours. Pricing reflects application complexity, with fruit grading systems reaching up to $100,000 per unit due to precision optics and food-grade materials.

FAQs

How to verify an automated sorting system manufacturer’s reliability?

Validate certifications (ISO 9001, CE) through issuing bodies and request facility audit reports. Analyze transaction history, focusing on on-time delivery records and post-installation support. Conduct video tours to confirm in-house production capabilities and engineering team involvement.

What is the typical lead time for automated sorting systems?

Standard systems require 30–45 days for production and testing. Custom configurations involving WMS integration or multi-directional sorting may extend timelines to 60–75 days. Air freight adds 5–10 days; sea shipping takes 25–40 days depending on destination.

Do manufacturers offer customization options?

Yes, leading suppliers provide full customization including sorting capacity (up to 12,000 packages/hour), chute configuration, software interface design, and sensor integration (weight, barcode, RFID, dimensioning). Minimum order quantities typically start at one set, with pricing adjusted for scale and complexity.

Can automated sorting systems be integrated with existing warehouse infrastructure?

Most manufacturers design modular systems compatible with existing conveyor networks and enterprise software platforms. Confirm communication protocols (e.g., TCP/IP, Modbus) and physical interface dimensions during the design phase to ensure seamless integration.

Are samples available before bulk ordering?

Due to system complexity, full-system sampling is rare. However, suppliers often provide functional demos via video or offer component-level testing (e.g., scanner accuracy, belt speed). Some may ship scaled-down prototypes for validation at buyer expense.