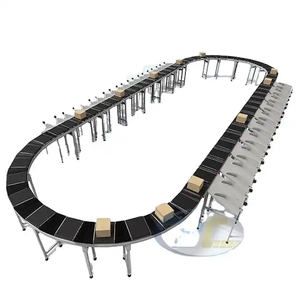

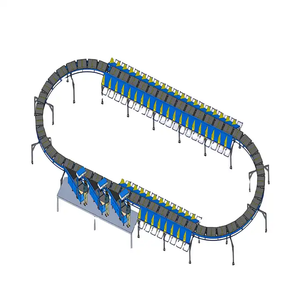

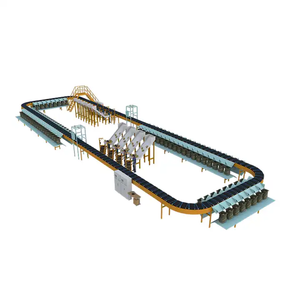

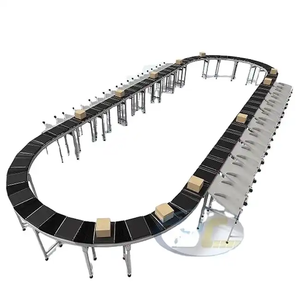

Automated Sorting Systems Manufacturer

Top sponsor listing

Top sponsor listing

1/15

1/15

1/25

1/25

CN

CN

About automated sorting systems manufacturer

Where to Find Automated Sorting Systems Manufacturers?

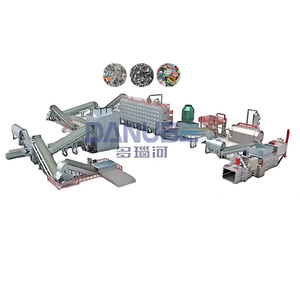

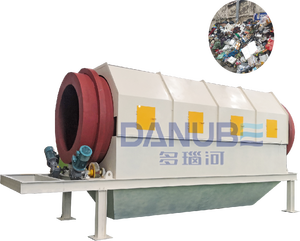

China remains the global epicenter for automated sorting systems manufacturing, with key production hubs concentrated in Guangdong, Zhejiang, and Shanghai. These regions host vertically integrated industrial ecosystems that support rapid prototyping, scalable production, and export-ready logistics. Shenzhen and Huizhou in Guangdong province are home to advanced intelligent equipment clusters specializing in conveyor automation and material handling integration. Shanghai’s robotics corridor fosters innovation in AI-driven parcel sorting and DWS (Dimensioning, Weighing, Scanning) technologies, while Zhejiang’s electrical engineering base enables precision control system development.

Manufacturers in these zones benefit from co-located component suppliers—servo motors, PLCs, sensors, and structural steel—reducing lead times by 20–30% compared to offshore alternatives. Facilities typically operate under ISO 9001-aligned quality management frameworks, with many offering CE-marked solutions compliant with European safety directives. Average factory sizes range from 3,000 to over 20,000 m², supporting monthly outputs of 10–50+ units depending on system complexity. This infrastructure enables OEMs and logistics operators to source high-reliability systems at competitive price points, with standard configurations available within 45–60 days.

How to Choose Automated Sorting Systems Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

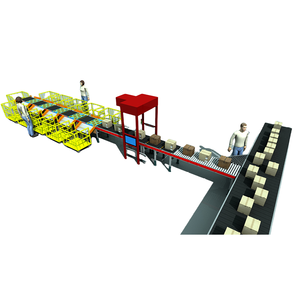

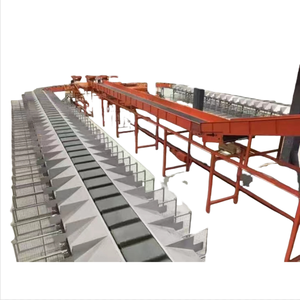

Verify adherence to international standards such as CE, ISO 9001, and where applicable, RoHS. For integration into automated warehouses or distribution centers, confirm compatibility with WMS/TMS platforms via Modbus, Profibus, or Ethernet/IP protocols. Assess design flexibility: leading suppliers offer customization in belt width (300–1,200 mm), frame materials (stainless steel, aluminum, carbon steel), motor configurations, and environmental protection (IP54/IP65 for dust/rain resistance).

Production Capacity Verification

Evaluate infrastructure through documented evidence:

- Minimum facility size of 3,000m² for full-line assembly and testing

- In-house engineering teams capable of layout simulation and 3D modeling

- Integrated fabrication capabilities including CNC machining, welding, and control panel assembly

Cross-reference delivery performance (target ≥98%) with response time metrics (≤2 hours preferred) to gauge operational responsiveness.

Transaction Security & After-Sales Support

Prioritize suppliers with verifiable on-time shipment records and transparent dispute resolution mechanisms. Confirm availability of remote commissioning support, operator training, and spare parts supply chains. Request test reports for load capacity, sorting accuracy (±1–2 mm), and mean time between failures (MTBF). For high-value contracts, utilize secure payment structures and pre-shipment inspections to mitigate risk.

What Are the Leading Automated Sorting Systems Manufacturers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Sample MOQ | Price Range (per set) |

|---|---|---|---|---|---|---|---|---|

| Huizhou Aifeiyuan Technology Co., Ltd. | Conveyors, Material Handling Equipment, Transmission Belts | Motor, color, material, size, belt design, frame, rainproof options | US $450,000+ | 100% | ≤1h | 27% | 1 set | Not specified |

| Senad Robot(Shanghai) Co., Ltd. | Automated Parcel Sorters, DWS Systems, Conveyor Equipment | Limited customization noted | US $60,000+ | 100% | ≤5h | 100% | 1 set | $4,500–$50,000 |

| Huayuan (Shenzhen) Intelligent Equipment Co., Ltd. | Automatic Sorters, DWS Conveyors, Storage Equipment | Size, material, application-specific adjustments | US $330,000+ | 100% | ≤3h | 50% | 1 set | $11,500–$28,000 |

| Zhejiang Xinli Electrical Equipment Co., Ltd. | Cross-belt Sorters, Logistics Sorting Systems, Weighing Scales | System configuration and integration support | US $6,000+ | 100% | ≤2h | - | 1 set | $50,000 |

| Guangdong Gosunm Intelligent Industry Co., Ltd. | DWS Systems, Custom Cross-belt Sorters, Intelligent Sorting Lines | Code, shape, weight, volume, label, material, logo customization | US $210,000+ | 100% | ≤2h | 60% | 1 set | $4,260–$19,820 |

Performance Analysis

Suppliers vary significantly in scale and specialization. Senad Robot and Zhejiang Xinli focus on high-end logistics automation, with Zhejiang Xinli commanding premium pricing ($50,000/set) for cross-belt systems designed for large-scale distribution networks. In contrast, Guangdong Gosunm offers cost-effective, highly customizable DWS solutions starting below $5,000, making it suitable for SMEs and regional fulfillment centers. Reorder rates indicate strong customer retention: Senad Robot and Gosunm report 100% and 60% repeat business respectively, reflecting confidence in reliability and service. All listed manufacturers maintain perfect on-time delivery records, with sub-3-hour average response times enhancing buyer engagement efficiency.

FAQs

How to verify automated sorting system manufacturer reliability?

Validate certifications (ISO, CE) through official registries and request factory audit reports or video walkthroughs. Analyze transaction history indicators such as reorder rate (>50% is favorable), on-time delivery consistency (target 100%), and response speed. Review product documentation for compliance with mechanical safety (e.g., EN 620) and electrical standards (e.g., IEC 60204-1).

What is the typical lead time for custom automated sorting systems?

Standard configurations ship within 30–45 days. Customized systems requiring engineering design, PLC programming, and integration testing typically require 45–75 days, depending on scope. Prototypes can be delivered in 25–35 days upon finalization of technical specifications.

Can suppliers provide turnkey installation and commissioning?

Yes, many manufacturers offer remote supervision, on-site installation guidance, and operator training packages. Some provide SCADA interface integration and real-time monitoring dashboards. Confirm service coverage and associated costs during procurement negotiations.

Do automated sorting system suppliers offer free samples?

Full-system sampling is uncommon due to size and cost; however, suppliers may provide subsystem demonstrations (e.g., a single sorting chute or scanner module) at reduced cost. Sample fees are often credited toward bulk orders exceeding one unit.

How to initiate a customization request?

Submit detailed requirements including throughput capacity (units/hour), item dimensions, weight range, desired sortation type (cross-belt, tilt-tray, sliding shoe), and environmental conditions. Reputable suppliers respond with layout drawings, component specifications, and control logic diagrams within 72 hours.