Automated Storage And Retrieval System

Top sponsor listing

Top sponsor listing

1/24

1/24

1/17

1/17

1/3

1/3

1/1

1/1

1/3

1/3

CN

CN

0

0

CN

CN

1/20

1/20

1/3

1/3

CN

CN

1/1

1/1

CN

CN

1/3

1/3

CN

CN

1/13

1/13

1/3

1/3

About automated storage and retrieval system

Where to Find Automated Storage and Retrieval System Suppliers?

China remains the central hub for automated storage and retrieval system (AS/RS) manufacturing, with key production clusters in Guangdong, Guangxi, and Henan provinces. These regions host vertically integrated facilities specializing in material handling systems, leveraging proximity to steel suppliers and logistics networks to streamline production. Guangzhou and Nanning-based manufacturers benefit from mature industrial ecosystems that support rapid prototyping and scalable fabrication of racking structures, robotic shuttles, and control systems.

The concentration of component suppliers—ranging from cold-rolled steel processors to automation module assemblers—within 50km radii enables efficient supply chain coordination. This integration reduces lead times for standard configurations to 30–45 days, while custom AS/RS solutions typically require 60–75 days. Buyers gain access to competitive pricing models, with localized production reducing material costs by 15–25% compared to Western counterparts. The presence of certified engineering teams within supplier organizations further supports turnkey deployment of high-density storage systems tailored to warehouse automation needs.

How to Choose Automated Storage and Retrieval System Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, quality assurance, and transactional reliability.

Technical and Production Capacity

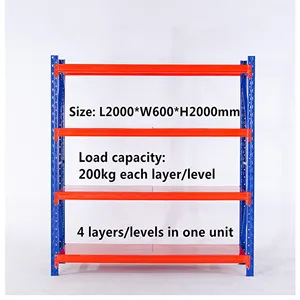

Assess whether suppliers possess in-house design and fabrication capabilities for load-bearing structures and motion control components. Preferred partners demonstrate CNC machining, precision welding, and powder coating processes. Verify customization scope including adjustable shelf spacing, layer count (typically 3–8 levels), load capacity (ranging from 200kg to over 1,000kg per bay), and integration readiness with warehouse management software (WMS).

Quality and Compliance Verification

Confirm adherence to international standards such as ISO 9001 for quality management. While not always explicitly stated, structural integrity testing for galvanized or painted steel components is critical. Review available performance metrics: top-tier suppliers report on-time delivery rates exceeding 98%, response times under 3 hours, and reorder rates above 25%, indicating customer satisfaction and operational consistency.

Order Flexibility and Risk Mitigation

Minimum order quantities (MOQs) vary significantly—from single units for modular shelving to 100+ kilograms for bulk steel components. Prioritize suppliers offering sample units or pilot installations before full-scale procurement. Utilize secure payment mechanisms and request detailed documentation covering material specifications, load test reports, and software interface protocols. For global shipments, clarify FOB terms, packaging standards, and export compliance procedures.

What Are the Best Automated Storage and Retrieval System Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Key Strengths |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Maobang Storage Equipment Co., Ltd. | Guangdong, CN | Stacking Racks & Shelves, Cargo & Storage Equipment | Limited | 93% | ≤3h | 23% | US $1.4M+ | High-volume output; proven logistics performance |

| Luoyang Morgie Electronic Commerce Co., Ltd. | Henan, CN | Heavy-duty industrial racks, layered storage systems | Extensive (color, thickness, capacity, layout) | 95% | ≤5h | <15% | US $540K+ | Broad customization; detailed engineering parameters |

| Guangxi Nanning Jianzhian Integrated Housing Co., Ltd. | Guangxi, CN | Steel storage shelves, mezzanine systems | Moderate (size, layers, weight capacity) | 98% | ≤2h | 28% | US $950K+ | Fast response; high delivery reliability |

| Guangzhou Eyda Storage Equipment Co., Ltd. | Guangdong, CN | Fully automated warehouse robots, CTU systems | High (load capacity, unit configuration) | 100% | ≤2h | 30% | US $230K+ | Advanced automation integration; perfect delivery record |

| AD RACKING STORAGE SYSTEMS PTE LTD | Singapore | Industrial racking, automatic pallet storage | OEM & customized packing options | - | ≤3h | - | - | Design flexibility; international market focus |

Performance Analysis

Guangzhou Eyda stands out with a 100% on-time delivery rate and specialization in fully automated robotic systems priced between $10,000–$35,000 per set, making it ideal for advanced warehouse automation projects. Guangxi Nanning Jianzhian offers strong operational efficiency with sub-2-hour response times and 98% punctuality, suitable for time-sensitive procurement cycles. Luoyang Morgie provides extensive customization across material, color, and structural dimensions, though its lower reorder rate suggests room for improvement in long-term client retention. AD RACKING, based in Singapore, serves international markets with OEM-focused offerings despite limited verifiable transaction data. Guangzhou Maobang leads in revenue volume, indicating robust production throughput for standardized storage equipment.

FAQs

How to verify automated storage and retrieval system supplier reliability?

Cross-check declared delivery performance and response metrics against platform-verified transaction histories. Request evidence of ISO certification, material test reports, and references for completed installations. Evaluate responsiveness through technical inquiries about load distribution calculations or WMS integration protocols.

What is the typical MOQ and pricing range?

MOQs range from 1 unit for pre-engineered modules to 100+ pieces or kilograms for bulk shelving components. Prices vary widely: basic steel shelves start at $11.92/unit, while complete automated robotic cells begin at $10,000/set depending on payload and control complexity.

Can suppliers customize AS/RS configurations?

Yes, leading suppliers offer customization in load capacity (200–500kg+ per level), number of tiers (3–8 layers), footprint dimensions, paint finish, and structural materials (galvanized or cold-rolled steel). Some provide CAD modeling and layout simulation upon request.

Do suppliers support global shipping and installation?

Most suppliers export internationally and work with freight forwarders to manage sea or air shipments. While delivery of components is standard, on-site installation support varies—confirm availability and associated costs during negotiation.

Are samples available before bulk ordering?

Sample policies differ. Some suppliers offer single-unit prototypes for validation, particularly for modular rack sections. Expect partial cost recovery for samples, especially for high-value automated units. Lead time for samples ranges from 15–30 days.