Automatic Bottle Capper

About automatic bottle capper

Where to Find Automatic Bottle Capper Suppliers?

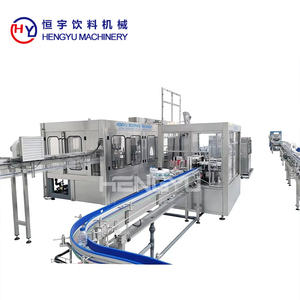

China leads global production of automatic bottle capping equipment, with key manufacturing clusters in Guangdong, Henan, and Guangzhou offering specialized capabilities. Guangdong province is home to advanced automation manufacturers leveraging integrated smart systems for high-speed rotary cappers, while Henan-based suppliers focus on cost-effective semi-automatic and pneumatic models suited for small to mid-sized beverage and chemical producers. These regions benefit from mature packaging machinery ecosystems supported by localized component sourcing—reducing lead times and assembly costs by 15–25% compared to non-specialized markets.

The industrial clusters enable vertical integration across filling, capping, labeling, and sealing lines, allowing suppliers to offer turnkey packaging solutions. Proximity to steel, electronics, and pneumatics suppliers ensures rapid prototyping and scalable production. Buyers gain access to facilities capable of producing 50–500 units per month, with average delivery windows of 30–45 days for standard configurations. The concentration of engineering talent and export logistics infrastructure further enhances supply chain reliability for international procurement.

How to Choose Automatic Bottle Capper Suppliers?

Procurement decisions should be guided by objective evaluation criteria to ensure performance, compliance, and long-term reliability:

Technical & Quality Compliance

Prioritize suppliers with verifiable adherence to international quality standards such as ISO 9001. For exports to regulated markets (EU, North America), confirm CE marking or equivalent safety certifications. Request documentation on motor efficiency, torque control systems, and material compatibility—particularly for food-grade or pharmaceutical applications requiring stainless steel contact surfaces and sanitary design.

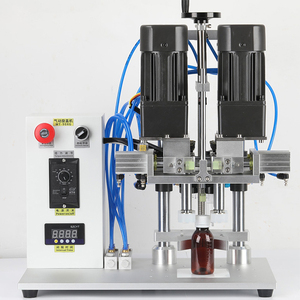

Production and Customization Capability

Assess supplier capacity through the following benchmarks:

- Minimum factory area exceeding 3,000m² for stable output

- In-house R&D teams supporting custom cap types (screw, snap, trigger spray) and bottle sizes (100ml–5L)

- Integration of vibration feeders, servo-driven capping heads, and programmable logic controllers (PLCs)

- Customization options including explosion-proof designs, atex-rated components, and multi-lane configurations

Cross-reference technical claims with product listings showing actual build specifications and pricing tiers.

Transaction and Risk Mitigation

Utilize secure payment methods such as escrow services to align payment milestones with shipment and inspection. Analyze supplier performance metrics: target on-time delivery rates above 95%, response times under 4 hours, and reorder rates indicating customer retention. Conduct video audits of production lines before finalizing bulk orders. Always request functional samples to validate capping accuracy, speed (up to 60–120 bottles per minute), and compatibility with your container and cap type.

What Are the Best Automatic Bottle Capper Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Zhengzhou Songtsam Machinery Equipment Co., Ltd. | Zhengzhou, CN | Filling Machines, Capping Machines, Packaging Lines | 100% | ≤4h | <15% | $6,000+ | $369–6,999 |

| Guangzhou Maiton Automation Packaging Equipment Co., Ltd. | Guangzhou, CN | Capping Machines, Filling Machines, Sealing Machines | 95% | ≤4h | 27% | $290,000+ | $1,300–5,800 |

| Guangdong New Zhen Xiang Smart Equipment Co., Ltd. | Guangdong, CN | Rotary Cappers, Trigger Spray Cappers, Custom Systems | 100% | ≤1h | 28% | $320,000+ | $8,900–16,990 |

| Guangzhou Tengde Machinery Equipment Co., Ltd. | Guangzhou, CN | Capping Machines, Labeling, Auxiliary Packaging | 80% | ≤1h | <15% | $40,000+ | $1,480–9,944 |

| Metica Machinery (Shanghai) Co., Ltd. | Shanghai, CN | Automatic Linear & Rotary Cappers | 100% | ≤3h | 40% | $430,000+ | $7,200–13,500 |

Performance Analysis

Metica Machinery (Shanghai) demonstrates strong customer loyalty with a 40% reorder rate and full on-time delivery record, indicating consistent quality and post-sale support. Guangdong New Zhen Xiang stands out for rapid responsiveness (≤1h) and high customization depth, particularly for specialty caps like trigger sprays and fine mist pumps. While Zhengzhou Songtsam offers entry-level models starting at $369, its low reorder rate suggests limited differentiation in competitive segments. Guangzhou Maiton balances mid-range pricing with solid delivery performance, making it suitable for buyers seeking reliable throughput without premium automation. Shanghai and Guangdong-based suppliers dominate higher-end production, offering PLC-controlled systems with integrated conveyors and fault diagnostics.

FAQs

How to verify automatic bottle capper supplier reliability?

Validate certifications (ISO, CE) through official registries and request test reports for motor durability, torque consistency, and material corrosion resistance. Review transaction history, focusing on dispute resolution records and customer feedback related to machine uptime and after-sales service.

What is the typical sampling timeline?

Standard sample production takes 10–20 days, depending on complexity. Custom configurations with specialized cap handling or explosion-proof components may require 30–40 days. Air freight shipping adds 5–10 business days globally.

Can suppliers provide customized capping solutions?

Yes, leading manufacturers offer full customization including cap feeder design, capping head height adjustment, bottle size adaptability, and integration with existing filling lines. Suppliers with in-house engineering teams can deliver 3D models within 72 hours and functional prototypes in 3–5 weeks.

What are common MOQ and pricing structures?

Most suppliers set MOQ at 1 unit for standard models, enabling low-risk evaluation. Pricing varies significantly by automation level: semi-automatic units range from $350–$1,500, fully automatic single-head systems from $1,800–$6,000, and high-speed rotary or multi-head lines from $8,000–$17,000. Volume discounts typically apply for orders over 5 units.

Do suppliers support global shipping and installation?

Yes, experienced exporters manage FOB and CIF shipments worldwide. Many offer remote commissioning support via video guidance. For complex installations, on-site technician deployment may be available at additional cost. Confirm inclusion of user manuals, spare parts kits, and electrical compatibility (voltage/frequency) prior to order confirmation.