Automatic Brick Making Machine Price List

CN

CN

About automatic brick making machine price list

Where to Find Automatic Brick Making Machine Suppliers?

China remains the global epicenter for automatic brick making machine manufacturing, with key industrial hubs concentrated in Shandong and Henan provinces. These regions host vertically integrated production ecosystems that combine raw material processing, casting, CNC machining, and final assembly under one supply chain. Shandong's machinery corridor—centered around Jinan and Qingdao—specializes in high-capacity, fully automated systems designed for export markets requiring compliance with international safety and performance standards. Henan, home to over half of China’s construction equipment suppliers, offers cost-efficient production supported by dense networks of component manufacturers and logistics providers based in Zhengzhou.

The regional clustering enables streamlined procurement, with many suppliers operating facilities within 50 kilometers of steel foundries, hydraulic system producers, and mold fabrication workshops. This localization reduces lead times by up to 30% compared to offshore alternatives and supports rapid prototyping and customization. Buyers benefit from scalable production runs, with standard order fulfillment typically completed within 30–45 days. The integration of automation technology and modular design principles allows for flexible output configurations, accommodating interlocking bricks, hollow blocks, pavers, and solid concrete units across diverse market needs.

How to Choose Automatic Brick Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify adherence to recognized quality management systems such as ISO 9001. For buyers in regulated markets (EU, North America), confirm CE marking or equivalent third-party certification for electrical control panels and hydraulic systems. Assess machine specifications including vibration frequency (typically 4,000–6,000 rpm), forming pressure (12–20 MPa), and programmable logic controller (PLC)-based automation. Request detailed CAD drawings and control system schematics prior to purchase.

Production Infrastructure Assessment

Evaluate supplier capabilities through objective metrics:

- Minimum factory area exceeding 3,000m² to ensure stable batch production

- In-house engineering teams capable of customizing mold types, conveyor integration, and stacking systems

- On-site testing protocols for hydraulic durability, motor efficiency, and structural steel integrity

Cross-reference facility scale with on-time delivery performance (target ≥97%) and reorder rates to assess reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as letter of credit or platform-backed escrow services until post-delivery inspection is completed. Prioritize suppliers offering sample units for field testing, particularly when procuring for large-scale infrastructure projects. Validate after-sales support availability, including spare parts inventory and remote troubleshooting via PLC diagnostics.

What Are the Best Automatic Brick Making Machine Suppliers?

| Company Name | Location | Verification Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

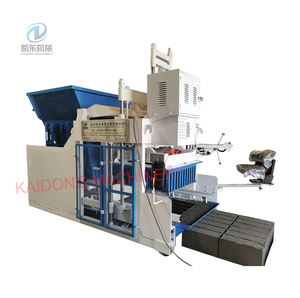

| Shandong Kaidong Construction Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | US $320,000+ | 100% | ≤2h | 18% | $3,000–60,000 | Yes |

| Qingdao HF Machinery Technology Co., LTD | Shandong, CN | Multispecialty Supplier | US $130,000+ | 100% | ≤5h | 25% | $13,500–52,000 | Yes |

| Zhengzhou Yingfeng Machinery Co., Ltd. | Henan, CN | - | US $210,000+ | 100% | ≤7h | 100% | $4,200–100,000 | Limited |

| Henan Chunyue Import & Export Trading Co., Ltd. | Henan, CN | - | US $10,000+ | 100% | ≤5h | <15% | $4,900–12,350 | No |

| Henan Province Gongyi City East China Metallurgical Coal Mine Machinery Factory | Henan, CN | - | Not disclosed | 100% | ≤7h | Not available | $4,000–5,999 | No |

Performance Analysis

Shandong-based suppliers like Kaidong and HF Machinery offer broad customization ranges and higher-end automation packages suitable for industrial-scale operations. Kaidong stands out with a wide price spectrum ($3K–$60K), indicating capacity to deliver both semi-automatic and fully integrated production lines. Qingdao HF demonstrates strong customer retention (25% reorder rate) and responsiveness, positioning it well for mid-tier commercial buyers. In Henan, Zhengzhou Yingfeng reports an exceptional 100% reorder rate, suggesting high end-user satisfaction despite limited customization transparency. Lower-priced offerings from Gongyi and Chunyue target budget-conscious buyers but lack evidence of engineering adaptability or premium component integration. All listed suppliers maintain perfect on-time delivery records, though response speed varies significantly—from ≤2 hours for top-tier vendors to over 5 hours for smaller exporters.

FAQs

What determines the price variation in automatic brick making machines?

Key cost drivers include automation level (manual feed vs. fully automatic palletizer integration), hydraulic pressure capacity, mold configuration complexity, and control system sophistication (e.g., touchscreen HMI with fault diagnostics). Machines producing 12,000+ units per 8-hour shift typically start above $45,000, while entry-level models under $6,000 serve small-scale producers with manual labor supplementation.

What is the typical MOQ and lead time?

Most suppliers require a minimum order quantity of 1 set, enabling pilot procurement. Standard lead times range from 25 to 40 days after deposit confirmation, depending on customization scope. Expedited builds may be available at additional cost for urgent deployments.

Can suppliers customize brick size and shape?

Yes, reputable manufacturers provide mold redesign services to produce specific block formats—including interlocking, hollow, solid, and paving stones—based on client specifications. Custom molds typically add 7–14 days to production timelines and may incur setup fees ranging from $500–$2,000 depending on complexity.

Do suppliers offer installation and training support?

Many suppliers include remote commissioning guidance via video and manuals. On-site technician deployment is often available at extra cost, covering machine setup, operator training, and initial run validation. Confirm service terms and travel expense policies before contract finalization.

How are shipments handled for heavy machinery?

Full container load (FCL) sea freight is standard for single-machine orders due to weight (ranging 3–20 metric tons). Suppliers typically quote FOB prices; buyers arrange destination port handling and inland transport. Proper crating and anti-corrosion coating are essential for long-distance maritime transit.