Automatic Flyash Bricks Machine

Top sponsor listing

Top sponsor listing

CN

CN

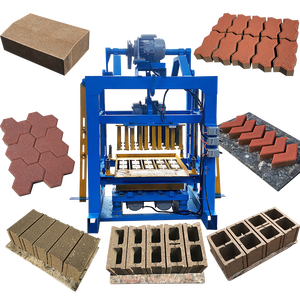

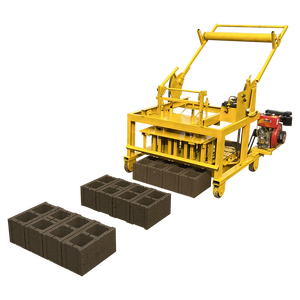

About automatic flyash bricks machine

Where to Find Automatic Flyash Bricks Machine Suppliers?

China remains the global epicenter for automatic flyash bricks machine manufacturing, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, hydraulic system integration, and final assembly under one supply chain. Shandong’s machinery corridor—centered around Linyi and Jining—leverages proximity to steel and casting hubs, reducing component procurement lead times by up to 25%. Henan, home to over half of China’s construction equipment manufacturers, offers superior logistics connectivity via Zhengzhou’s multimodal transport network, enabling faster export fulfillment.

The regional specialization supports both standard and engineered-to-order production models. Factories in these zones typically operate modular production lines capable of assembling semi-automatic to fully automated systems, including conveyor integration, batching plants, and curing setups. Buyers benefit from localized supplier networks where mold fabrication, hydraulic power units, and control panels are sourced within a 50-kilometer radius, contributing to cost efficiency and shorter delivery cycles (average 30–45 days for standard configurations). Production scalability ranges from small-capacity QT4-15 models (output: ~1,500 blocks/hour) to high-volume QT12-15 systems producing up to 4,500 blocks/hour.

How to Choose Automatic Flyash Bricks Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

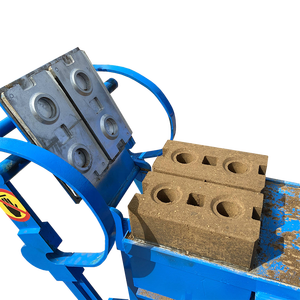

Confirm suppliers offer ISO 9001-certified design and manufacturing processes as a baseline quality benchmark. For international compliance, CE marking is essential for market access in Europe and many developing economies. Request documentation on core system specifications—hydraulic pressure ratings (typically 16–20 MPa), PLC control systems (Siemens or equivalent), and mold durability (minimum 10,000 cycles without deformation). Validate compatibility with flyash-based mixes (up to 70% flyash content) and interlocking block designs.

Production Infrastructure Assessment

Evaluate facility scale and engineering capacity through verifiable indicators:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house R&D teams focused on automation upgrades and energy efficiency

- Integrated capabilities in CNC machining, welding, and hydraulic testing

Cross-reference online revenue data and order fulfillment rates (target ≥98% on-time delivery) to assess operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Prioritize suppliers with documented after-sales support, including remote troubleshooting and spare parts availability. Conduct sample testing to verify block density (≥1,800 kg/m³), compressive strength (>10 MPa), and dimensional accuracy (±1mm tolerance). Customization feasibility should be confirmed through detailed technical consultations covering mold design, colorant integration, and packaging automation.

What Are the Best Automatic Flyash Bricks Machine Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Linyi Aiwei International Trade Co., Ltd. | Shandong, CN | Brick Making Machinery, Concrete Mixers, Crushers | Conveyor, mold, color, capacity, hydraulic system, silo, packaging | 100% | ≤1h | US $30,000+ | 16% |

| Henan Best Link Import And Export Trading Co., Ltd. | Henan, CN | Brick Making Machinery, Mining Equipment, Chemical Agents | Limited customization reported | 100% | ≤1h | US $240,000+ | <15% |

| Shandong Canhua International Trade Co., Ltd. | Shandong, CN | Brick Making Machinery, Paver Blocks, Hollow Blocks | Mold, color, automation level, material feed, power configuration | 100% | ≤2h | US $170,000+ | <15% |

| Shandong Ruidaming New Material Co., Ltd. | Shandong, CN | Brick Making Machinery, Concrete Mixers | Customizable molds, block shape, automation features | 100% | ≤1h | US $8,000+ | <15% |

| Zhengzhou Canmax Machinery & Equipment Co., Ltd. | Henan, CN | Brick Making Machinery, Clay Brick Machines | Color, logo, mold, packaging, block shape, material mix | 100% | ≤3h | US $330,000+ | 31% |

Performance Analysis

Zhengzhou Canmax stands out with the highest reorder rate (31%) and robust customization capabilities, indicating strong customer satisfaction despite a slightly longer response time. Linyi Aiwei and Henan Best Link demonstrate high responsiveness (≤1h) and proven export volume, with the latter reporting the second-highest online revenue. Shandong-based suppliers dominate in production flexibility, offering extensive options for mold design, automation level, and material handling integration. All listed suppliers maintain perfect on-time delivery records, suggesting reliable logistics execution. Buyers seeking turnkey solutions should prioritize companies with demonstrated experience in full-line installations, including batching, mixing, and curing systems.

FAQs

How to verify automatic flyash bricks machine supplier reliability?

Validate ISO 9001 or CE certifications through official registries. Request factory audit reports or video walkthroughs confirming in-house machining, assembly lines, and quality testing procedures. Analyze transaction history, focusing on consistent on-time delivery performance and post-sale service responsiveness.

What is the typical MOQ and lead time?

Minimum Order Quantity is generally 1 set, accommodating pilot projects and small-scale operations. Lead time averages 30–45 days for standard machines; customized systems may require 50–60 days depending on complexity.

Can suppliers customize machine configuration?

Yes, leading suppliers offer configurable options including mold design (interlocking, hollow, solid), automation level (semi-auto to fully automatic), hydraulic system pressure, and auxiliary components like conveyors, silos, and packaging units. Technical drawings and 3D layouts are typically provided within 72 hours of inquiry.

Do manufacturers support global shipping and installation?

Most suppliers manage international freight via FOB or CIF terms and provide basic installation guidance. For complex deployments, on-site commissioning support may be available at additional cost. Confirm inclusion of electrical compatibility (voltage/frequency) and language-specific operation manuals.

Are samples or test runs available before purchase?

While full-machine trials are uncommon, suppliers often provide produced brick samples for quality assessment. Some offer live video demonstrations of running machines with specified raw materials. Sample bricks can be used to verify compressive strength, water absorption, and dimensional consistency per national standards (e.g., IS 2180, GB/T 11968).