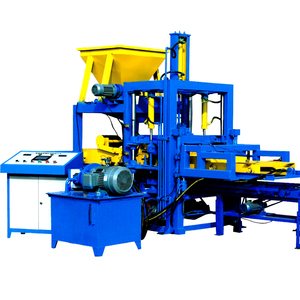

Automatic Hollow Block Making Machine Price

1/12

1/12

1/28

1/28

1/24

1/24

1/17

1/17

1/18

1/18

CN

CN

1/33

1/33

About automatic hollow block making machine price

Where to Find Automatic Hollow Block Making Machine Suppliers?

China remains the global epicenter for automatic hollow block making machine production, with concentrated manufacturing hubs in Henan, Shandong, and Hebei provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, hydraulic system integration, and final assembly under one supply chain. Henan’s Zhengzhou and Shandong’s Qingdao are particularly notable for their specialization in concrete machinery, offering buyers access to mature supplier networks where component sourcing, technical engineering, and export logistics converge within a 50-kilometer radius.

The clustering effect enables significant cost efficiencies—localized steel and casting suppliers reduce material costs by 18–22% compared to non-specialized regions. Facilities typically operate on a lean production model with monthly outputs ranging from 30 to 120 units per line, depending on automation level. Most manufacturers support both standard and custom configurations, including diesel-electric hybrid power systems, interlocking mold designs, and conveyor-integrated setups. Lead times for standard models average 25–40 days, with expedited builds possible within 15 days for pre-engineered variants.

How to Choose Automatic Hollow Block Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate risks and ensure long-term operational reliability.

Technical & Quality Compliance

Verify ISO 9001 certification as a baseline indicator of quality management. For markets requiring regulatory compliance (EU, North America, GCC), confirm CE marking or equivalent safety certifications. Request documentation on core component testing—particularly for hydraulic pumps, vibration motors, and control panels—to assess durability under continuous operation. Machines should meet industry-standard performance metrics, such as block output rates (6,000–12,000 units/8hr) and dimensional accuracy (±1mm tolerance).

Production Capacity Verification

Assess infrastructure maturity through key indicators:

- Minimum factory footprint of 3,000m² to support dedicated casting, machining, and assembly zones

- In-house capabilities for CNC machining, welding, and mold fabrication

- Dedicated R&D teams focused on automation upgrades and energy efficiency improvements

Cross-reference these with on-time delivery performance (target ≥97%) and reorder rates (>25% indicates strong customer retention).

Customization & Transaction Security

Leading suppliers offer modular customization for mold types (hollow, solid, paver), power sources (electric, diesel, three-phase), and automation levels (semi-auto to fully automatic). Confirm availability of design support for non-standard block shapes and packaging configurations. Use secure transaction mechanisms such as escrow services or letter of credit terms. Prioritize suppliers with documented after-sales service frameworks, including remote troubleshooting and spare parts provisioning.

What Are the Best Automatic Hollow Block Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Product Range (Price Range) | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhengzhou Canmax Machinery & Equipment Co., Ltd. | Henan, CN | US $320,000+ | 100% | 31% | ≤3h | $808–$6,500 | Color, material, size, logo, mold, packaging, capacity |

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | US $500,000+ | 97% | 54% | ≤5h | $12,500–$25,000 | Block size, batching system, automation level, noise reduction, pallet design, hydraulic technology, mold types |

| Shandong Canhua International Trade Co., Ltd. | Shandong, CN | US $170,000+ | 100% | <15% | ≤2h | $8,600–$29,500 | Conveyor, color, interlocking molds, pallets, automation, hydraulic systems, labeling |

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | US $80,000+ | 100% | <15% | ≤4h | $289–$5,421 | Limited (focus on standard models) |

| Qingdao Hf Machinery Co., Ltd. | Shandong, CN | US $110,000+ | 100% | 25% | ≤6h | $18,500–$49,500 | High-end customization for large-scale projects |

Performance Analysis

Qingdao Darifeng stands out with the highest reorder rate (54%), indicating strong customer satisfaction and repeat business, supported by extensive customization depth across automation, noise control, and mold engineering. Zhengzhou Canmax offers broad price-tier coverage—from entry-level ($808) to mid-range models—making it suitable for SMEs and emerging markets. Shandong Canhua combines aggressive pricing with rapid response times (≤2h), though lower reorder rates suggest room for improvement in post-sale engagement.

Hebei Zhongke Jiantong provides the most budget-accessible options, including sub-$300 electric models ideal for small workshops, but lacks advanced customization features. Qingdao Hf Machinery targets premium commercial projects with high-capacity machines priced above $40,000, often deployed in large infrastructure developments. Buyers seeking scalability should prioritize suppliers with proven experience in containerized turnkey solutions and multi-machine installations.

FAQs

What is the typical MOQ for automatic hollow block making machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set, facilitating pilot procurement and small-scale adoption. Bulk discounts generally apply starting at 3+ units, with optimized shipping rates for full-container loads (1x40ft can accommodate 2–4 machines depending on size).

How long does production and delivery take?

Standard lead time ranges from 25 to 40 days post-deposit, including manufacturing, testing, and export preparation. Express production is available in 15–20 days for pre-configured models. Sea freight transit adds 15–35 days depending on destination port.

Can suppliers customize molds for specific block dimensions?

Yes, all listed suppliers offer mold customization for block size, shape (hollow, solid, interlocking), and surface texture. Technical drawings or sample blocks are required to initiate tooling design. Mold development typically takes 7–14 days with validation via test runs before shipment.

Do manufacturers provide installation and training support?

Many suppliers include remote setup guidance via video and manuals. On-site technician deployment is available at additional cost (typically $150–$250/day plus travel). Training covers machine operation, maintenance protocols, mix ratio calibration, and fault diagnostics.

Are spare parts readily available after purchase?

Reputable suppliers maintain inventory of critical wear components—vibration motors, seals, hydraulic valves, and mold plates—and offer replacement kits. Plan to procure a starter spare parts package (valued at 5–8% of machine cost) during initial order to minimize downtime.