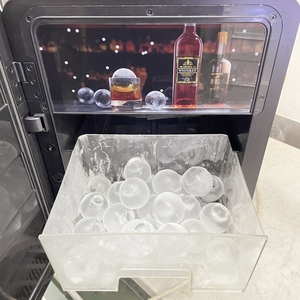

Automatic Ice Maker

About automatic ice maker

Where to Find Automatic Ice Maker Suppliers?

China remains the central hub for automatic ice maker manufacturing, with key production clusters concentrated in Zhejiang, Jiangsu, and Guangxi provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, evaporator coil production, and injection molding of food-grade plastic components. Proximity to Tier-1 ports such as Ningbo and Shanghai enables efficient export logistics, reducing outbound shipping lead times by 7–10 days compared to inland manufacturing zones.

The industrial ecosystem supports rapid scaling, with many suppliers operating facilities exceeding 5,000m² and maintaining in-house R&D teams focused on energy efficiency and compact design. This integration allows for streamlined production cycles—standard models typically achieve assembly within 15–20 days post-order confirmation. Buyers benefit from localized access to critical subsystems like hermetic compressors and electronic control boards, contributing to a 15–25% cost advantage over non-Asian manufacturers. High-volume producers report monthly outputs ranging from 3,000 to 10,000 units, accommodating both retail packaging and bulk commercial configurations.

How to Choose Automatic Ice Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate risk and ensure product conformity:

Quality & Compliance Verification

Confirm adherence to international safety and performance standards. CE, ETL, or UL certification is essential for market entry in Europe and North America. Validate compliance through documented test reports covering electrical insulation, temperature stability, and water contact materials (FDA-compliant plastics). Suppliers should provide evidence of ISO 9001-certified quality management systems to assure consistent process control.

Production & Customization Capacity

Assess operational scale and flexibility using the following benchmarks:

- Facility size ≥3,000m² indicating established production infrastructure

- In-house engineering capability for custom voltage (110V/220V), plug types, or capacity modifications (10–500kg/day output)

- Available customization options: color finishes, OEM branding, logo imprinting, and packaging design

Cross-reference stated capabilities with online revenue metrics and reorder rates to gauge reliability and customer satisfaction.

Transaction Security & Lead Time Management

Prioritize suppliers with verifiable on-time delivery records (≥96%) and response times under 3 hours. Utilize secure payment mechanisms such as escrow services to align financial release with shipment milestones. Standard lead times range from 25 to 35 days for containerized orders; expedited production may reduce this by 5–7 days at additional cost. Request sample units before full-scale procurement to evaluate build quality, noise levels, and ice cycle consistency.

What Are the Best Automatic Ice Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Whalfly Tek Co., Ltd. | Guangdong, CN | Ice Makers (471) | US $9,000+ | 100.0% | ≤1h | <15% | No | 1 piece |

| Guangxi Bsnow Refrigeration Equipment Co., Ltd. | Guangxi, CN | Ice Machines, Commercial Units | US $60,000+ | 96.0% | ≤3h | <15% | Yes | 1 set |

| Nantong Wuding Technology Co., Ltd. | Jiangsu, CN | Ice Machines (380) | US $60,000+ | 100.0% | ≤3h | 16% | No | 1 set |

| Shanghai Bingsu Refrigeration Technology Co., LTD. | Shanghai, CN | Ice Machines (401) | US $20,000+ | 100.0% | ≤1h | <15% | No | 1 piece/set |

| NINGBO KAISON ELECTRIC APPLIANCE CO.,LTD | Zhejiang, CN | Commercial Cube Ice Makers | US $120,000+ | 100.0% | ≤1h | 15% | Yes | 2–9 pieces |

Performance Analysis

NINGBO KAISON leads in transaction volume and responsiveness, offering customization and 100% on-time delivery, though minimum order quantities start at 2 pieces. Whalfly Tek and Shanghai Bingsu stand out for low MOQs (1 piece) and sub-hour response times, making them suitable for small buyers and sample testing. Guangxi Bsnow and Nantong Wuding specialize in commercial-grade units with scalable capacities up to 500kg/day and support for OEM branding. While most suppliers maintain reorder rates below 16%, indicating limited repeat business, their high on-time fulfillment suggests reliable execution for one-off or project-based procurement.

FAQs

How to verify automatic ice maker supplier reliability?

Validate certifications (CE, ETL, ISO 9001) through issuing bodies and request factory audit reports. Analyze response consistency, order fulfillment history, and customer feedback focusing on post-delivery technical support and defect resolution timelines.

What is the typical sampling timeline for ice makers?

Standard sample production takes 10–18 days, depending on model complexity. Shipping via express courier adds 5–7 days internationally. Some suppliers offer free samples contingent upon subsequent bulk orders.

Can suppliers accommodate OEM/ODM requests?

Yes, select manufacturers provide full ODM/OEM services including custom外观, control panel layouts, and branded packaging. Minimum volumes typically start at 50 units, with lead times extending by 7–10 days for design validation and tooling adjustments.

What are common MOQs and pricing ranges?

MOQs vary from 1 piece for residential models to 2–9 units for commercial machines. Unit prices range from $129.99 for compact portable units to over $3,800 for high-capacity gourmet ice systems. Volume discounts are standard beyond 50 units.

How are ice makers packaged and shipped?

Units are double-boxed with EPS foam protection and palletized for container loads. FOB terms are standard; suppliers often partner with freight forwarders to manage air or sea shipments. Pre-shipment inspections can be arranged to verify quantity and functionality prior to dispatch.